Lo mhlahlandlela ukutshela konke mayelana nemishini yokumaka nge-laser; lokho abayikho, ukuthi basebenza kanjani, izinzuzo abazilethayo, kanye nezicelo zabo ezingase zibe khona.

Okuqukethwe

Uyini umshini wokumaka we-laser?

Usebenza kanjani umshini wokumaka we-laser?

Izinzuzo zomshini wokumaka we-laser

Izinhlelo zokusebenza zemishini yokumaka i-laser

Izinqubo ezahlukene zomshini wokumaka we-laser

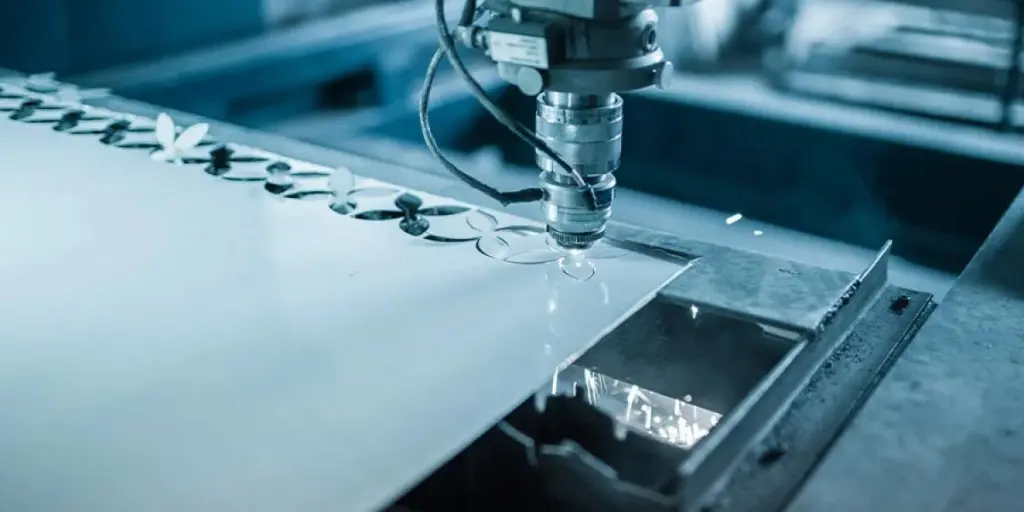

Uyini umshini wokumaka we-laser?

Ukumaketha kwe-laser isebenzisa i-laser beam ukumaka unomphela zonke izinhlobo zezinto. Umgomo wokumaka nge-laser ukuthi i-laser beam ilungisa ukubukeka kwendawo engaphezulu ngokusabela okubangwa lapho amandla e-laser eshaya indawo. Lokhu kungenzeka ngokusebenzisa izindlela ezihlukahlukene:

1. Ukukhishwa kwempahla (i-laser engraving); ngezinye izikhathi kususwa enye isendlalelo esingaphezulu esinombala.

2. Ukuncibilikisa insimbi, ngaleyo ndlela ukuguqula isakhiwo esingaphezulu.

3. Ukushiswa kancane (i-carbonization) ngokuvamile kwephepha, amakhadibhodi, ukhuni, noma ama-polymers.

4. Ukuguqulwa (i-bleaching) kombala (izithasiselo ze-laser zezimboni) kumpahla yepulasitiki.

5. Ukunwetshwa kwe-polymer, isibonelo ngokuhwamulisa isithasiselo.

6. Ukukhiqizwa kwezici ezingaphezulu, njengamabhamuza amancane njengesibonelo.

Ngokuskena i-laser beam (isb, ngezibuko ezimbili ezihambayo), kungenzeka ukuthi ubhale ngokushesha izinhlamvu, izimpawu, amabha amakhodi, nezinye ihluzo, usebenzisa i-vector noma i-raster scanning. Enye indlela ukusebenzisa imaski ekhonjiswe kucwecwe lokusebenza (ukumaka iphrojekthi, ukumaka imaski). Le ndlela ilula futhi iyashesha futhi ingasetshenziswa ngisho nezinto zokusebenza ezihambayo. Nokho, ayiguquguquki kancane kunokuskena.

Ukumaka nge-laser ukumaka noma ukulebula kwezingcezu zokusebenza nezinto zokwakha nge-laser beam. Sizobheka izindlela ezahlukene lokhu okwenzeka ngazo, njengokuqopha, ukususa, ukufaka amabala, ukuhushula, nokukhihliza amagwebu. Kuye ngohlobo lwempahla kanye nekhwalithi oyifunayo, ngayinye yalezi zinqubo inezinzuzo zayo kanye nokubi.

Usebenza kanjani umshini wokumaka we-laser?

Izisekelo zobuchwepheshe be-Laser

Wonke ama-laser aqukethe izingxenye ezintathu eziyinhloko:

1. Umthombo wamandla, ngokuvamile owaziwa ngokuthi umthombo wepompo wangaphandle.

2. I-laser medium esebenzayo.

3. Izibuko ezimbili noma ngaphezulu ezakha i-resonator.

1. Umthombo wepompo uqondisa amandla angaphandle ukuze i-laser futhi kungaba optical, ugesi, noma amakhemikhali kuye ngokuthi medium esebenzayo.

2. I-laser medium esebenzayo yizinto lapho isenzo se-laser senzeka khona. Kuye ngomklamo, kungaba ingxube yegesi (i-CO2 laser), amakristalu aqinile (i-YAG laser), noma ama-optical fibers ahlanganiswe nezinto ezingavamile zensimbi yomhlaba (fiber laser). Uma amandla ephonswa endaweni esebenzayo, aguqulwa kancane abe amandla emisebe.

3. I-resonator yakha amandla okukhanya ku-laser beam. Yakheka ngokubeka izibuko ezimbili noma ngaphezulu zibhekane ukuze ukukhanya okuphuma phakathi kwazo kubonakale emuva naphambili. Esinye sezibuko yi-one-way mirror. Imisebe ye-laser medium esebenzayo ikhuliswa ku-resonator. Inani elithile kuphela lemisebe elingashiya i-resonator ngesibuko sendlela eyodwa. Lena imisebe ye-laser.

Izinzuzo zomshini wokumaka we-laser

Ukumaka okunembe okuphezulu ngekhwalithi engaguquki

Ngenxa yokunemba okuphezulu kokumaka nge-laser, ngisho nezithombe ezithambile, amafonti anephuzu elingu-1, namajiyometri amancane ngempela azofundeka ngokucacile. Ngesikhathi esifanayo, ukumaka nge-laser marker kuqinisekisa imiphumela eqhubekayo yekhwalithi ephezulu.

Isivinini esikhulu sokumaka

Ukumaka nge-laser kungenye yezinqubo zokumaka ezisheshayo ezitholakala emakethe. Lokhu kubangela ukukhiqiza okuphezulu kanye nezinzuzo zezindleko zebhizinisi lakho. Ngokuya ngesakhiwo nosayizi, imithombo ye-laser ehlukene (isb., ama-laser fibre) noma imishini ye-laser (isb., ama-galvo lasers) ingasetshenziselwa isivinini esisheshayo.

Ukumaka okuhlala isikhathi eside

I-laser etching ingunaphakade, ngakho-ke izodinga ukwenziwa kanye kuphela, futhi imelana nemihuzuko, ukushisa, namakhemikhali afana nama-asidi. Ngokuya ngezilungiselelo zepharamitha ye-laser, izinto ezithile zingamakwa ngaphandle kokulimaza indawo.

Izinhlelo zokusebenza zemishini yokumaka i-laser

Imishini yokumaka i-laser ube nezinhlobonhlobo ezinkulu zezicelo:

1. Ukwengeza izinombolo zezingxenye, amabhakhodi, izinsuku zokusetshenziswa, njll., emaphaketheni okudla, amabhodlela, njll.

2. Ukwengeza ulwazi olulandelekayo lokulawula ikhwalithi.

3. Ukumaka amabhodi esekethe aphrintiwe (ama-PCB), izingxenye zikagesi, namakhebuli.

4. Amalogo okuphrinta, amabhakhodi, nolunye ulwazi ngemikhiqizo.

Uma kuqhathaniswa nobunye ubuchwepheshe bokumaka obufana nokuphrinta i-ink jet kanye nokumaka kwemishini, ukumaka nge-laser kunezinzuzo eziningi, okuhlanganisa isivinini sokucubungula esiphezulu kakhulu, izindleko zokusebenza eziphansi (akukho ukusetshenziswa kwezinto ezisetshenziswayo), izinga eliphezulu eliqhubekayo, imiphumela ehlala isikhathi eside, ihlanzekile, akukho ukungcola, futhi ingamaka izici ezincane kuyilapho iguquguquka kakhulu.

Izinto zepulasitiki, ukhuni, amakhadibhodi, iphepha, isikhumba, ne-acrylic kuvame ukumakwa ngamalaser anamandla aphansi we-CO2. Kodwa-ke, lawa ma-laser awafaneleki kangako endaweni eyinsimbi ngenxa yokumuncwa kwawo okuphansi kumaza amade. Amaza amaza e-laser ahlukene angatholwa ngamalaser a-Nd:YAG ampontshwa isibani (imvamisa u-Q) noma ngamalaser efiber, afaneleka kakhulu endaweni eyinsimbi. Amandla ama-laser asetshenziselwa ukumaka ngokuvamile aphakathi kuka-10 kuya ku-100 W. Amaza amaza amafushane afana no-532 nm, atholwe ngokuphindaphindwa kabili kwama-laser e-YAG, angaba nenzuzo, kodwa abize. Ukuze kuphawulwe izinsimbi njengegolide, ene-spectrum yokumunca ecishe ibe ngu-350-416 nm, amaza amaza amafushane e-laser abalulekile.

Metals

Insimbi engagqwali, i-aluminium, igolide, isiliva, i-titanium, ithusi, iplatinum, noma ithusi kungamakwa unomphela.

Ama-Lasers asesetshenziswe iminyaka eminingana manje, ikakhulukazi ekuqoshweni nasekumaka izinsimbi. Akuzona kuphela izinsimbi ezithambile ezifana ne-aluminium ezingamakwa; insimbi noma ama-alloys aqine kakhulu nawo angamakwa ngokunembile, ngokufundeka, futhi ngokushesha kusetshenziswa i-laser. Ngezinsimbi ezifana nama-alloys ensimbi, kungenzeka futhi usebenzise izimpawu ezimelana nokugqwala ngaphandle kokulimaza isakhiwo esingaphezulu usebenzisa uphawu lokufaka i-annealing. Imikhiqizo eyenziwe ngensimbi imakwe ngama-lasers kulo lonke uhla olukhulu lwezimboni.

Plastics

I-Polycarbonate (PC), i-Polyamide (PA), i-Polyethylene (PE), i-Polypropylene (PP), i-Acrylonitrile butadiene styrene copolymer (ABS), i-Polyimide (PI), i-Polystyrene (PS), i-Polymethyl methacrylate (PMMA), i-Polyester (PES).

Ipulasitiki ingamakwa noma iqoshwe ngama-lasers ngezindlela eziningi. Ungakwazi ukumaka amapulasitiki amaningi ahlukene asetshenziswa ezentengiselwano nge-fiber laser, okuhlanganisa i-polycarbonate, i-ABS, i-polyamide, nokunye okuningi. Isiphetho sizoba unomphela, sisheshe, futhi sibe nekhwalithi ephezulu. Ngenxa yezikhathi eziphansi zokusetha nokuvumelana nezimo okunikezwayo nge-laser yokumaka, ungakwazi ngisho nosayizi abancane benqwaba ngokwezomnotho.

Izinto eziphilayo

Izinto eziphilayo zidinga inani elincane kuphela lamandla e-laser ukuze ziwanikeze amamaki ahlala njalo, acacile. Ochwepheshe bathuthukise izinhlelo ze-Laser Marking ezibhekana ngokuphelele nale mfuneko. Amasistimu amandla awo angalawuleka ukuze kugcinwe ukukhiqizwa kokushisa ngaphakathi kwemikhawulo oyifunayo.

Ingilazi kanye ne-ceramics

Izinto ezifana nengilazi kanye ne-ceramics kunzima ukumaka ngokuphepha usebenzisa izindlela zendabuko. Ngale njongo, i-STYLECNC ithuthukise ubuchwepheshe obukwazi ukusebenzisa ukugqama okuphezulu, okumaka okungaqhekeki engilazini nasezintweni zobumba. Cabanga nje, akukho ukuphuka noma imikhiqizo emoshiwe.

Izinqubo ezahlukene zomshini wokumaka we-laser

Ukumaka kwe-anealing

I-Annealing marking wuhlobo olukhethekile lwe-laser etching yezinsimbi. I-laser beam ishisa kancane insimbi ibangele inqubo ye-oxidation ngaphansi kwendawo ebonakalayo, okuholela ekushintsheni kombala endaweni yensimbi. Akukho okukhishiwe futhi indawo ayilimele, ngakho-ke ilungele izinhlelo zokusebenza lapho ukugqwala kungakheka khona.

Ukudweba kwe-Laser

Ngesikhathi sokuqoshwa nge-laser, i-laser beam ivele incibilikise into, futhi igesi enomfutho ophezulu, ngokuvamile i-Nitrogen, isetshenziselwa ukufutha insimbi encibilikisiwe iphume ku-kerf. Umbono ongaphezulu uwumbhalo oqoshiwe.

Ukususwa kwe-laser

Ngesikhathi sokususwa, i-laser beam isusa noma yimaphi ama-topcoat afakwe ku-substrate. Ukungafani kukhiqizwa ngenxa yemibala ehlukene ye-topcoat kanye ne-substrate. Izinto ezijwayelekile eziyilaser ezimakwe ngale ndlela zihlanganisa i-aluminiyamu e-anodized, izinsimbi eziboshiwe, ama-foil, amafilimu, noma ama-laminates. Ingasetshenziswa futhi ukususa upende.

Ukukhihliza amagwebu

Lokhu kusetshenziselwa izinto ze-polymer. Ngesikhathi sokugwetshwa, ugongolo lwe-laser luncibilikisa izinto. Inqubo yokuncibilika ikhiqiza amabhamuza egesi ezintweni, abonisa ukukhanya ngokuhlukanayo. Ukumakwa kuzoba lula kunezindawo ezingakabhalwanga. Lolu hlobo lokumaka nge-laser lusetshenziswa ikakhulukazi kumapulasitiki amnyama.

I-Carbonizing

I-Carbonizing inika amandla umehluko oqinile ezindaweni ezikhanyayo. Ngesikhathi senqubo ye-carbonizing i-laser enamandla kakhulu ibangela ukuthi ungqimba olungaphezulu lwento luhwamuke bese kukhishwa umoya-mpilo, i-hydrogen, noma inhlanganisela yawo womabili amagesi. Amabhondi ekhabhoni-carbon akhiwa futhi okusele kuyindawo emnyama (i-carbonized).

I-Carbonizing ingasetshenziselwa ama-polymers noma ama-biopolymers afana nokhuni noma isikhumba. Njengoba i-carbonizing ihlale iholela kumamaki amnyama, ukungafani kwezinto ezimnyama ngeke kube kuhle.

Ukuqoshwa kombala

Ukuqoshwa kombala kuyinqubo yokumaka esebenzisa umthombo we-MOPA fiber laser ukwengeza umbala endaweni yensimbi njengensimbi engagqwali, i-titanium, njll. I-MOPA ibhekisela ekucushweni okuhlanganisa i-laser eyinhloko (noma i-seed laser) kanye ne-optical amplifier ukuze kukhuliswe amandla okukhiphayo. Ingaphezulu ligcwele umbala owufunayo.

Ukumaka kwe-3D

Lokhu kusetshenziselwa ukumaka izimo ze-3D nezinto kunezindawo eziyisicaba. I-lens ye-optical enwetshiwe ye-beam ilawulwa ngekhompuyutha endaweni ye-optical axis ngokunyakaza okuphindaphindayo kwesivinini esikhulu. Ukulungiswa okunamandla kobude bokugxila be-laser beam kudala izindawo ezigxile ezindaweni ezihlukene ngaphezulu futhi kugcina umfaniswano wokumaka futhi unembile.

Umthombo ovela Stylecnc

Umshwana wokuzihlangula: Ulwazi olubekwe ngenhla luhlinzekwa yi-Stylecnc ngaphandle kwe-Cooig.com. I-Cooig.com ayenzi izethulo namawaranti mayelana nekhwalithi nokuthembeka komdayisi nemikhiqizo.