Ngo-2024, imakethe yomhlaba wonke yamarobhothi emboni yensimbi, okuhlanganisa nemishini yokumaka i-laser, yafinyelela ku-$0.77 billion, nokuqagela ukuthi kuzokhula kakhulu ngo-2029. Njengoba amabhizinisi elungiselela u-2025, isidingo sokunemba nokusebenza kahle kwezokukhiqiza siqhuba ukwamukelwa kobuchwepheshe bokumaka be-laser obuthuthukisiwe. Lesi sihloko sicubungula okucatshangelwayo okubalulekile kokukhetha imishini yokumaka nge-laser yensimbi, enikeza imininingwane ngamathrendi akamuva kanye nezinto ezintsha ezilolonga imboni.

Okuqukethwe:

- Isidingo Esikhulayo Semishini Yokumaka I-Laser Embonini Yensimbi

- Ukuhlaziywa Okujulile Kwemakethe Yemishini Yokumaka I-Laser

- Ukucatshangelwa Okubalulekile Lapho Ukhetha Imishini Yokumaka I-Laser Yensimbi

- Izici Ezithuthukile Nezinto Ezintsha Emishini Yokumaka Nge-Laser

– Ukuthobela Umthetho kanye Namazinga Okuphepha

- Amathrendi Nentuthuko Yesikhathi esizayo ku-Laser Marking Technology

- Ukugoqa

Isidingo Esikhulayo Semishini Yokumaka I-Laser Embonini Yensimbi

Imishini yokumaka i-laser iya ngokuya idingeka embonini yensimbi ngenxa yesidingo sokunemba nokusebenza kahle ekukhiqizeni. Ngo-2024, imakethe yomhlaba wonke yamarobhothi emboni yensimbi, ehlanganisa nemishini yokumaka nge-laser, kulindeleke ukuthi ifinyelele ku-$0.77 billion. Le makethe kulindeleke ukuthi ikhule ngesilinganiso sokukhula sonyaka esihlanganisiwe (CAGR) sika-2.24% ukusuka ngo-2024 kuya ku-2029, sifinyelele ku-$0.86 billion ngo-2029. I-China ihola imakethe ngemali engenayo elinganiselwa ku-$119.9 million ngo-2024, igqamisa isikhundla sayo esiphezulu.

I-United States nayo idlala indima enkulu, ngemakethe yayo yemishini nemishini ebiza ama-dollar ayizigidi eziyizinkulungwane ezingama-194.2 ngo-2024, okukhombisa isidingo esinamandla semishini ethuthukisiwe, okubandakanya nobuchwepheshe bokumaka nge-laser. Umphumela womkhakha kulindeleke ukuthi ufinyelele ku-$0.4 trillion, ngezinga lokukhula lika-0.98% kule minyaka emihlanu ezayo. Lokhu kwanda kuqhutshwa ukukhuphuka kwesidingo somhlaba wonke, intuthuko eqhubekayo yezobuchwepheshe, kanye nokukhula kokutshalwa kwezimali kokuzenzakalelayo kanye nokwenza idijithali.

EJalimane, imakethe yamathuluzi nemishini, ehlanganisa imishini yokumaka nge-laser, kulindeleke ukuthi ikhule ku-CAGR ka-2.83% kusukela ngo-2024 kuya ku-2029. Lokhu kukhula kugqugquzelwa ukugxila kwezwe kubunjiniyela obunembayo nokukhiqizwa kwekhwalithi ephezulu, okwenza iJalimane ibambe iqhaza elibalulekile emakethe yomhlaba. Umbono omuhle usekelwa futhi isidingo semikhiqizo emisha nekhathalela imvelo.

Ukuhlaziywa Okujulile Kwemakethe Yemishini Yokumaka I-Laser

Lapho ukhetha imishini yokumaka ye-laser yensimbi, izici ezimbalwa ezibalulekile kufanele zicatshangelwe ukuze kuqinisekiswe ukusebenza kahle nokubuyisela ekutshalweni kwezimali. Lokhu kufaka phakathi uhlobo lobuchwepheshe be-laser, ukuphuma kwamandla, isivinini sokumaka, ukunemba, nokuhambisana nezinsimbi ezihlukahlukene. Ukuqonda lezi zici kusiza amabhizinisi enze izinqumo ezinolwazi ezihambisana nezidingo zabo ezithile.

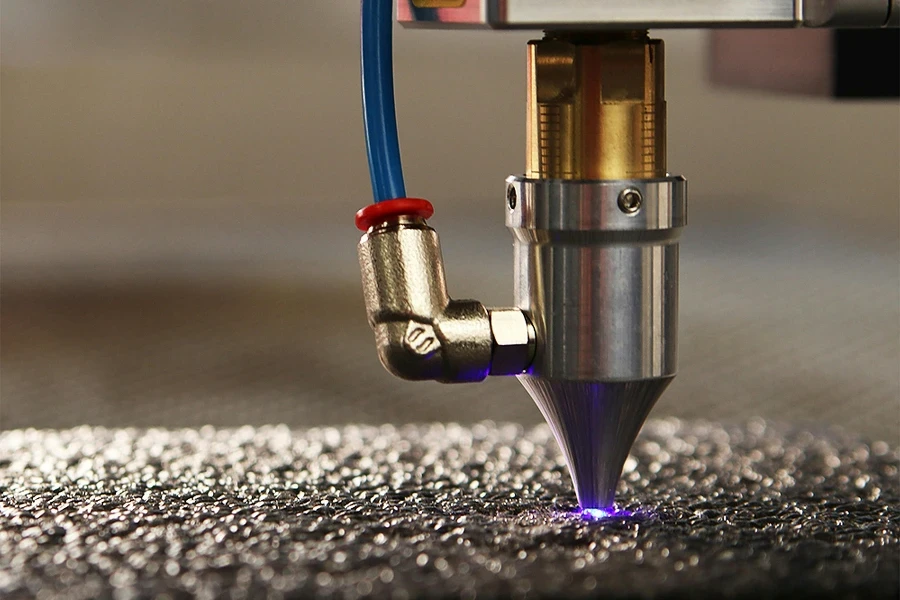

1. Laser Technology Izinhlobo

Uhlobo lobuchwepheshe be-laser luwukucatshangelwa okuyisisekelo lapho ukhetha umshini wokumaka we-laser wensimbi. Izinhlobo ezijwayelekile zifaka amalaser efiber, amalaser e-CO2, namalaser e-Nd:YAG. Ama-fiber lasers asebenza kahle kakhulu futhi afanele ukumaka izinsimbi ngenxa yekhwalithi yawo enhle kakhulu ye-beam nokusebenza kahle kwamandla. Asebenza kahle kakhulu ekumaka insimbi engagqwali, i-aluminium, nezinye izinsimbi. Amalaser e-CO2, nakuba eguquguquka, awasebenzi kahle ezinsimbi ngaphandle kokwelashwa okwengeziwe. Ama-laser e-Nd:YAG, aziwa ngamandla awo aphezulu, alungele ukuqoshwa okujulile nokumaka ezinsimbini eziqinile. Uhlobo ngalunye lwe-laser lunikeza izinzuzo ezihlukile, futhi ukukhetha kuncike ezidingweni ezithile zohlelo lokusebenza.

2. Okukhipha Amandla Nesivinini

Ukukhishwa kwamandla kubalulekile njengoba kunquma ikhono lomshini lokumaka izinsimbi ezahlukene. Ukukhipha amandla aphezulu kuvumela isivinini sokumaka esisheshayo kanye nokuqoshwa okujulile, okubalulekile ezinhlelweni zokusebenza zezimboni ezidinga ukuphuma okuphezulu. Isibonelo, i-50W fiber laser ingamaka kahle izinsimbi ngesivinini esikhulu, iyenze ifanelekele ukukhiqizwa ngobuningi. Nokho, amandla aphezulu aphinde asho ukwanda kokusetshenziswa kwamandla, ngakho-ke kubalulekile ukulinganisa izidingo zamandla nezindleko zokusebenza. Ukwengeza, isivinini sokumaka kufanele sihambisane nezidingo zokukhiqiza ukuze kuqinisekiswe ukusebenza kahle ngaphandle kokubeka engcupheni ikhwalithi.

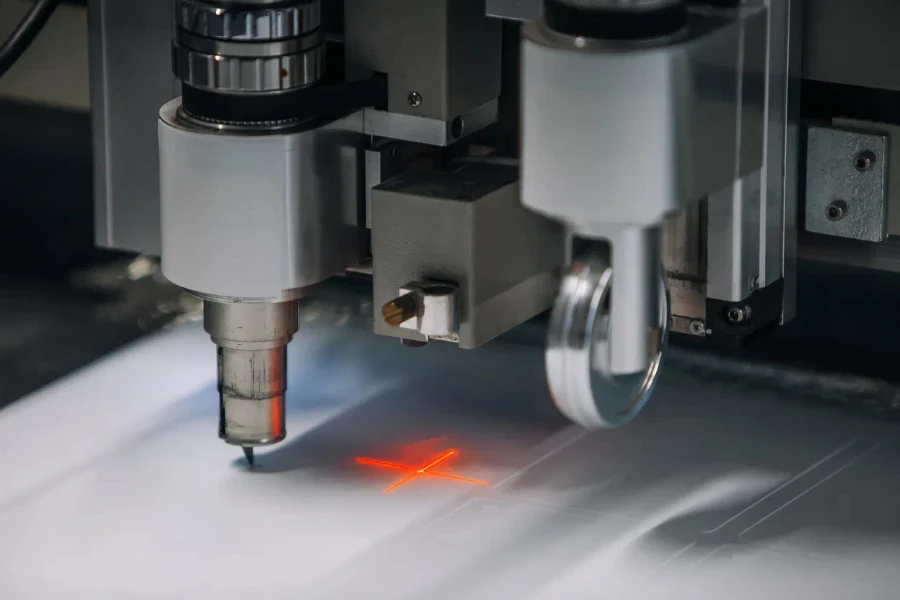

3. Ukunemba Nokunemba

Ukunemba nokunemba kubalulekile ezinhlelweni ezidinga imiklamo enemininingwane neyinkimbinkimbi. Umshini wokumaka we-laser kufanele unikeze amandla okulungiswa okuphezulu ukuze ukhiqize amamaki acacile nanembile. Lokhu kubaluleke kakhulu ezimbonini ezifana ne-aerospace nemishini yezokwelapha, lapho ukumaka kufanele kuhlangabezane nezindinganiso zekhwalithi eziqinile. Imishini enama-optics athuthukisiwe kanye nezinhlelo zokulethwa kwezigxobo zingafinyelela ukunemba okuphakeme, iqinisekise ukuthi ngisho nemininingwane emincane ikhiqizwa kabusha ngokunembile. Ukuhlola ukulungiswa komshini kanye nokucaciswa kokuphindaphinda kunganikeza imininingwane ngamakhono awo anembayo.

4. Ukuhambisana Nezinsimbi Ezihlukahlukene

Ukuhambisana komshini wokumaka we-laser onezinsimbi ezahlukene kungenye into ebalulekile. Eminye imishini yenzelwe izinsimbi ezithile, kuyilapho eminye ihlinzeka ngokuguquguquka kulo lonke uhla lwezinto. Isibonelo, ama-laser efiber afaneleka kahle ukumaka izinsimbi njengensimbi engagqwali, i-titanium, nethusi, kuyilapho ama-laser e-Nd:YAG ekwazi ukuphatha izinsimbi eziqinile njenge-tungsten ne-carbide. Ukuqonda izinhlobo zezinsimbi ezidinga ukumakwa kuzoqondisa ukukhethwa kobuchwepheshe be-laser obufanele kanye nokucushwa komshini.

5. Isondlo kanye Nokwesekwa

Izidingo zokunakekela kanye nezinsizakalo zokusekela zibalulekile ekuqinisekiseni ukuphila isikhathi eside nokwethembeka kwemishini yokumaka ngelaser. Imishini enezidingo ezincane zokunakekelwa kanye nezinsizakalo zosekelo eziqinile zinganciphisa isikhathi sokungasebenzi kanye nokuphazamiseka kokusebenza. Kubalulekile ukuhlola ukutholakala kwezingxenye ezisele, ukwesekwa kobuchwepheshe, nezinketho zewaranti. Abakhiqizi abanikeza ukusekelwa okuphelele kwangemuva kokuthengisa, okuhlanganisa nezinsizakalo zokuqeqesha nokunakekela, bahlinzeka ngenani elengeziwe nokuthula kwengqondo emabhizinisini atshala imali kubuchwepheshe bokumaka nge-laser.

Ukucatshangelwa Okubalulekile Lapho Ukhetha Imishini Yokumaka I-Laser Yensimbi

Lapho ukhetha imishini yokumaka ye-laser yensimbi, izici ezimbalwa ezibalulekile kufanele zicatshangelwe ukuze kuqinisekiswe ukusebenza kahle nokubuyisela ekutshalweni kwezimali. Lokhu kufaka phakathi uhlobo lobuchwepheshe be-laser, ukuphuma kwamandla, isivinini sokumaka, ukunemba, nokuhambisana nezinsimbi ezihlukahlukene. Ukuqonda lezi zici kusiza amabhizinisi enze izinqumo ezinolwazi ezihambisana nezidingo zabo ezithile.

1. Laser Technology Izinhlobo

Uhlobo lobuchwepheshe be-laser luwukucatshangelwa okuyisisekelo lapho ukhetha umshini wokumaka we-laser wensimbi. Izinhlobo ezijwayelekile zifaka amalaser efiber, amalaser e-CO2, namalaser e-Nd:YAG. Ama-fiber lasers asebenza kahle kakhulu futhi afanele ukumaka izinsimbi ngenxa yekhwalithi yawo enhle kakhulu ye-beam nokusebenza kahle kwamandla. Asebenza kahle kakhulu ekumaka insimbi engagqwali, i-aluminium, nezinye izinsimbi. Amalaser e-CO2, nakuba eguquguquka, awasebenzi kahle ezinsimbi ngaphandle kokwelashwa okwengeziwe. Ama-laser e-Nd:YAG, aziwa ngamandla awo aphezulu, alungele ukuqoshwa okujulile nokumaka ezinsimbini eziqinile. Uhlobo ngalunye lwe-laser lunikeza izinzuzo ezihlukile, futhi ukukhetha kuncike ezidingweni ezithile zohlelo lokusebenza.

2. Okukhipha Amandla Nesivinini

Ukukhishwa kwamandla kubalulekile njengoba kunquma ikhono lomshini lokumaka izinsimbi ezahlukene. Ukukhipha amandla aphezulu kuvumela isivinini sokumaka esisheshayo kanye nokuqoshwa okujulile, okubalulekile ezinhlelweni zokusebenza zezimboni ezidinga ukuphuma okuphezulu. Isibonelo, i-50W fiber laser ingamaka kahle izinsimbi ngesivinini esikhulu, iyenze ifanelekele ukukhiqizwa ngobuningi. Nokho, amandla aphezulu aphinde asho ukwanda kokusetshenziswa kwamandla, ngakho-ke kubalulekile ukulinganisa izidingo zamandla nezindleko zokusebenza. Ukwengeza, isivinini sokumaka kufanele sihambisane nezidingo zokukhiqiza ukuze kuqinisekiswe ukusebenza kahle ngaphandle kokubeka engcupheni ikhwalithi.

3. Ukunemba Nokunemba

Ukunemba nokunemba kubalulekile ezinhlelweni ezidinga imiklamo enemininingwane neyinkimbinkimbi. Umshini wokumaka we-laser kufanele unikeze amandla okulungiswa okuphezulu ukuze ukhiqize amamaki acacile nanembile. Lokhu kubaluleke kakhulu ezimbonini ezifana ne-aerospace nemishini yezokwelapha, lapho ukumaka kufanele kuhlangabezane nezindinganiso zekhwalithi eziqinile. Imishini enama-optics athuthukisiwe kanye nezinhlelo zokulethwa kwezigxobo zingafinyelela ukunemba okuphakeme, iqinisekise ukuthi ngisho nemininingwane emincane ikhiqizwa kabusha ngokunembile. Ukuhlola ukulungiswa komshini kanye nokucaciswa kokuphindaphinda kunganikeza imininingwane ngamakhono awo anembayo.

4. Ukuhambisana Nezinsimbi Ezihlukahlukene

Ukuhambisana komshini wokumaka we-laser onezinsimbi ezahlukene kungenye into ebalulekile. Eminye imishini yenzelwe izinsimbi ezithile, kuyilapho eminye ihlinzeka ngokuguquguquka kulo lonke uhla lwezinto. Isibonelo, ama-laser efiber afaneleka kahle ukumaka izinsimbi njengensimbi engagqwali, i-titanium, nethusi, kuyilapho ama-laser e-Nd:YAG ekwazi ukuphatha izinsimbi eziqinile njenge-tungsten ne-carbide. Ukuqonda izinhlobo zezinsimbi ezidinga ukumakwa kuzoqondisa ukukhethwa kobuchwepheshe be-laser obufanele kanye nokucushwa komshini.

5. Isondlo kanye Nokwesekwa

Izidingo zokunakekela kanye nezinsizakalo zokusekela zibalulekile ekuqinisekiseni ukuphila isikhathi eside nokwethembeka kwemishini yokumaka ngelaser. Imishini enezidingo ezincane zokunakekelwa kanye nezinsizakalo zosekelo eziqinile zinganciphisa isikhathi sokungasebenzi kanye nokuphazamiseka kokusebenza. Kubalulekile ukuhlola ukutholakala kwezingxenye ezisele, ukwesekwa kobuchwepheshe, nezinketho zewaranti. Abakhiqizi abanikeza ukusekelwa okuphelele kwangemuva kokuthengisa, okuhlanganisa nezinsizakalo zokuqeqesha nokunakekela, bahlinzeka ngenani elengeziwe nokuthula kwengqondo emabhizinisini atshala imali kubuchwepheshe bokumaka nge-laser.

Izici Ezithuthukile Nezinto Ezintsha Emishini Yokumaka I-Laser

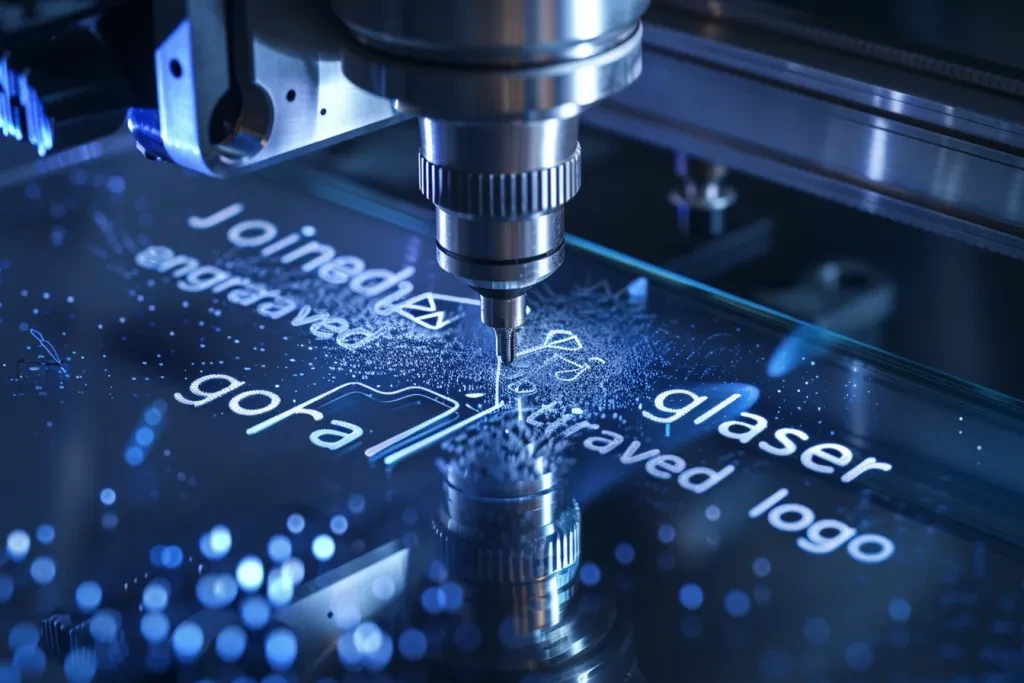

Imboni yokumaka nge-laser iyathuthuka ngokuqhubekayo, ngobuchwepheshe obusha nezici ezithuthukisa amakhono emishini. Ukuqonda lezi ntuthuko kungasiza amabhizinisi asebenzise izinto ezintsha zakamuva ukuze kwenziwe ngcono ukusebenza nokusebenza kahle.

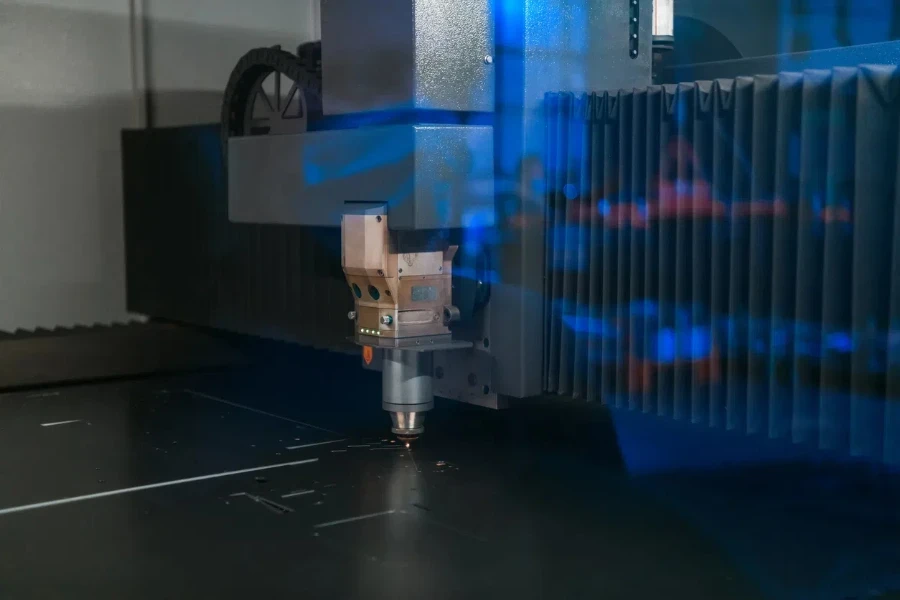

Ukuhlanganisa ne-Automation Systems

Imishini yesimanje yokumaka i-laser ivamise ukufaka amakhono okuhlanganisa namasistimu ezishintshayo, okuvumela ukusebenza okungenamthungo phakathi kwemigqa yokukhiqiza. Lokhu kuhlanganiswa kungafaka izingalo zerobhothi zokuphatha impahla, amasistimu okuthutha okumaka okuqhubekayo, nezindawo zesofthiwe zokuqapha nokulawula kwesikhathi sangempela. Ukuzenzakalela akukhulisi nje kuphela ukukhiqiza kodwa futhi kuqinisekisa ikhwalithi engaguquki ngokunciphisa amaphutha abantu. Amabhizinisi afuna ukuthuthukisa izinqubo zawo zokukhiqiza kufanele acabangele imishini enezici ezizenzakalelayo ezithuthukile.

Amakhono Esoftware Athuthukisiwe

Isoftware idlala indima ebalulekile ekusebenzeni nasekusebenziseni izinto ezihlukahlukene kwemishini yokumaka ngelaser. Izixazululo zesofthiwe ezithuthukisiwe zinikeza izici ezifana nokumaka idatha eguquguqukayo, ukukhiqizwa kwebhakhodi, kanye nekhono lokumaka le-3D. Lezi zici zivumela amabhizinisi ukuthi enze ukumaka ngendlela oyifisayo kwezinhlelo zokusebenza ezahlukene, kusukela kumbhalo olula kuye kwimidwebo eyinkimbinkimbi. Ukwengeza, ukuxhumana okusebenziseka kalula nokuhambisana namafomethi wefayela ahlukahlukene kungenza kube lula ukuklama kanye nenqubo yokumaka, kuyenze ifinyeleleke kuma-opharetha anamazinga ahlukahlukene obuchwepheshe.

Ukusebenza kahle kwamandla kanye nomthelela wemvelo

Ukusebenza kahle kwamandla kuya ngokuya kuba semqoka ekukhethweni kwemishini yezimboni, okuhlanganisa nemishini yokumaka i-laser. Imishini eyonga amandla ayigcini nje ngokunciphisa izindleko zokusebenza kodwa futhi inciphisa umthelela wendawo. Ukuqamba okusha okufana nezilungiselelo ze-eco-mode, ezinciphisa ukusetshenziswa kwamandla ngezikhathi zokungenzi lutho, kanye nokusetshenziswa kwemithombo ye-laser eyonga amandla kunomthelela kuzinjongo zokusimama. Amabhizinisi azibophezele ekwehliseni i-carbon footprint yawo kufanele abeke kuqala imishini enezici ezonga amandla.

Ukuthobela Umthetho kanye Namazinga Okuphepha

Ukuhambisana nezindinganiso zokulawula kanye nezidingo zokuphepha kubalulekile lapho kukhethwa imishini yokumaka nge-laser yensimbi. Ukuqinisekisa ukuthi imishini ihlangabezana nemithetho eqondene nemboni kungavimbela izinkinga zomthetho futhi kuthuthukise ukuphepha emsebenzini.

Imithetho Eqondene Nemboni

Izimboni ezahlukene zinemithetho ethile mayelana nokumaka izingxenye zensimbi. Isibonelo, imboni ye-aerospace idinga ukuhambisana namazinga afana ne-AS9100 ukuze uthole ukulandeleka nokuqinisekiswa kwekhwalithi. Ngokufanayo, abakhiqizi bemishini yezokwelapha kufanele bahambisane nemithetho ye-FDA yokuhlonza umkhiqizo. Ukukhetha umshini wokumaka we-laser ohlangabezana nalawa mazinga aqondene nomkhakha kubalulekile ekugcineni ukuthobela nokuqinisekisa ubuqotho bomkhiqizo.

Izici zokuphepha kanye nezitifiketi

Ukuphepha kuyinkinga enkulu lapho usebenzisa imishini yokumaka ye-laser. Imishini kufanele ifakwe izici zokuphepha ezifana nezindawo ezivalekile, amasistimu e-interlock, nemisebenzi yokumisa izimo eziphuthumayo ukuze kuvinjelwe izingozi nokulimala. Ukwengeza, izitifiketi ezinjengokumaka kwe-CE kanye namazinga e-ISO akhombisa ukuthi umshini uhlangabezana nezimpawu zokuphepha nekhwalithi zomhlaba jikelele. Amabhizinisi kufanele abeke phambili imishini enezici zokuphepha eziphelele nezitifiketi zokuvikela abaqhubi kanye nokugcina indawo yokusebenza ephephile.

Ukucatshangelwa Kwemvelo kanye Nezempilo

Izinqubo zokumaka nge-laser zingadala intuthu nezinhlayiya ezingase zibe yingozi empilweni kubasebenzisi. Imishini efakwe izinhlelo ezisebenzayo zokukhipha intuthu kanye nokuhlunga inganciphisa lezi zingozi ngokususa ukukhishwa okuyingozi endaweni yokusebenza. Ukwengeza, ukuhambisana nemithethonqubo yezemvelo mayelana nokulahlwa kwemfucuza kanye nokukhipha imfucumfucu kubalulekile ekusebenzeni okuzinzile. Amabhizinisi kufanele ahlole ukucatshangelwa kwemvelo kanye nempilo kwemishini yokumaka nge-laser ukuze kuqinisekiswe indawo yokusebenza ephephile futhi ethobelayo.

Amathrendi Nentuthuko Yekusasa Kubuchwepheshe Bokumaka Nge-Laser

Imboni yokumaka nge-laser ilungele intuthuko enkulu, eqhutshwa izinto ezintsha zobuchwepheshe kanye nezidingo zemakethe ezithuthukayo. Ukuqonda lezi zindlela kungasiza amabhizinisi ukuthi ahlale ngaphambi kwejika futhi asebenzise amathuba asafufusa.

I-Miniaturization kanye nokuphatheka

Njengoba ubuchwepheshe buthuthuka, kunomkhuba okhulayo obheke ku-miniaturization kanye nokuphatheka kwemishini yokumaka nge-laser. Imishini emincane nephathekayo inikeza ukuguquguquka nokuba lula, okuvumela amabhizinisi ukuthi enze imisebenzi yokumaka ezindaweni ezihlukahlukene. Le threndi ifaneleka kakhulu ezimbonini ezifana nezezimoto kanye ne-aerospace, lapho ukumaka kusayithi kuvame ukudingeka. Imishini ephathekayo enezinketho ezisebenza ngebhethri nokuxhumana okungenantambo kulindeleke ukuthi ithole ukuduma eminyakeni ezayo.

Ukudidiyelwa kobuhlakani bokwenziwa

I-Artificial intelligence (AI) iya ngokuya ihlanganiswa emishinini yokumaka nge-laser ukuze kuthuthukiswe ukusebenza nokusebenza kahle. Ama-algorithms e-AI angakwazi ukuthuthukisa amapharamitha wokumaka, athuthukise ukunemba, futhi abikezele izidingo zokunakekela, ehlise isikhathi sokuphumula nezindleko zokusebenza. Ukwengeza, amasistimu ombono anamandla e-AI anganika amandla ukuhlolwa kwekhwalithi yesikhathi sangempela, aqinisekise ukuthi izimpawu ziyahlangabezana nezindinganiso zekhwalithi. Ukuhlanganiswa kwe-AI kuhlelelwe ukuguqula imboni yokumaka nge-laser, kunikeze amazinga amasha okuzenzakalela kanye nobuhlakani.

Ukwandiswa Kwezindawo Zokufaka Isicelo

Izindawo zokufaka izicelo zemishini yokumaka nge-laser ziyanda ngale kwezimboni zendabuko. Imikhakha esafufusa efana ne-electronics, amandla avuselelekayo, kanye nokukhiqiza okungeziwe iya ngokuya yamukela ubuchwepheshe bokumaka nge-laser ukuhlonza umkhiqizo kanye nokulandeleka. Lokhu kwanda kuqhutshwa isidingo sekhwalithi ephezulu, izimpawu ezihlala isikhathi eside ezingamelana nezindawo ezinokhahlo kanye nezinqubo zokukhiqiza eziyinkimbinkimbi. Amabhizinisi akule mikhakha esafufusa kufanele ahlole amandla emishini yokumaka nge-laser ukuze athuthukise ukusebenza kwawo kanye nokunikelwa kwemikhiqizo.

Ukufaka phezulu

Ukukhetha umshini wokumaka we-laser ofanele wensimbi kuhilela ukucatshangelwa ngokucophelela kwezinto ezihlukahlukene, okuhlanganisa ubuchwepheshe be-laser, ukuphuma kwamandla, ukunemba, nokuhambisana nokulawula. Ngokuhlala benolwazi mayelana nentuthuko yakamuva namathrendi, amabhizinisi angenza izinqumo zamasu ezithuthukisa amakhono awo okukhiqiza kanye nokuncintisana.