Embonini yesimanje yokukhiqiza, izikhungo zokujika ze-CNC kanye nezintambo seziphenduke izingcezu ezimbili zemishini ebaluleke kakhulu. Isidingo salawa mathuluzi besilokhu sikhula kakhulu ngenxa yesidingo sezingxenye ezisezingeni eliphezulu nezinembayo zezinhlelo zokusebenza zezimboni eziningi.

Le bhulogi ihlola izici zabo kanye nokwehluka, ihlinzeka ngemininingwane yokwenza izinqumo ezithuthukisiwe uma kuziwa ekukhetheni phakathi kwalezi zixazululo ezimbili zezimboni.

Okuqukethwe

Isikhungo sokujika kanye nokubukeka kwemakethe ye-lathe

Izinhlobo eziyisihluthulelo zezikhungo zokujika kanye nezintambo

Izikhungo eziphendukayo uma ziqhathaniswa nama-lathes: uyini umehluko?

Isiphetho

Isikhungo sokujika kanye nokubukeka kwemakethe ye-lathe

Izikhungo eziphendukayo kanye nezintambo kuguqule indlela abakhiqizi abakhiqiza ngayo izingxenye ezinembayo. Le mishini inezici ezithuthukile nezingxenye ezithuthukisa ukusebenza kahle nokukhiqiza, okuholela ekwandeni kwesidingo.

Usayizi wemakethe yezikhungo ezishintshayo namandla

Intuthuko eqhubekayo emkhakheni wemishini yezimboni iholele ekwandeni kwesidingo izikhungo eziphendukayo. Lokhu kufakazelwa ekukhuleni kwemakethe yomhlaba wonke yemishini ye-CNC, eyaziswa kakhulu US$82.5 billion ngo-2022 futhi kulindeleke ukuthi ikhule ngenani lokukhula elihlanganisiwe lonyaka (CAGR) lika-8.7% ukuze lifinyelele ku-US $ 185.4 billion ngo-2032.

Isidingo semishini yokuguqula sisheshiswe yizinto eziningi, okuhlanganisa:

- Ukwanda kwemisebenzi yezimboni edinga izikhungo zokujika ukuze zenze izingxenye zenjini, amashafu, amagiya, amavalvu, nezixhumi.

- Amazinga aphezulu wokuzenzakalela aphumela ekusebenzeni kahle kakhulu nasekukhiqizeni, izindleko ezincishisiwe zabasebenzi, kanye nezikhathi zomjikelezo osheshayo

- Ukuhlanganiswa kobuchwepheshe obuthuthukisiwe, obufana nezinhlelo ze-CNC nezilawuli, ezinikeza isivinini esiphezulu futhi zikhulise ikhwalithi yemikhiqizo.

- Amazinga aphezulu okunemba nokunemba.

Usayizi wemakethe ye-Lathes namandla

Isidingo samalathesi siyaqhubeka nokukhula ngenxa yokukhula kwezimboni emhlabeni wonke kanye nokwanda kwemisebenzi yokukhiqiza. Ngo-2022, imakethe yomhlaba wonke yama-lathes yaqanjwa njengenani US $ 24.0 billion futhi kulindeleke ukuthi ikhule ku-CAGR ka-5% ngo-2023-2028 ukuze ifinyelele ku-US $ 32.7 billion ngo-2028.

Izinto ezahlukahlukene eziqhuba ukukhula kwemakethe yama-lathes, okuhlanganisa:

- Ukwanda kwesidingo ezimbonini zokukhiqiza ezifana nezimoto, i-aerospace, ezokwakha, namandla

- Abakhiqizi bafuna ukuguquguquka ngamalebula athuthuke kakhulu kwezobuchwepheshe

- Ukuhlanganiswa kokuhlanganiswa kwe-CNC kanye ne-automation, okwandisa umkhiqizo kanye nezikhathi zokusetha.

Izinhlobo eziyisihluthulelo zezikhungo zokujika kanye nezintambo

Turning izikhungo kanye izihlakala zivame ukwakhiwa ukuze kuhlangatshezwane nezidingo zemishini ehlukene. Kunamamodeli amaningi atholakalayo emakethe, ngalinye linezici ezihlukile, ezivumela abakhiqizi ukuthi bakhethe umshini ofaneleka kakhulu ngezidingo zabo nezinqubo zokukhiqiza.

Izikhungo eziphendukayo

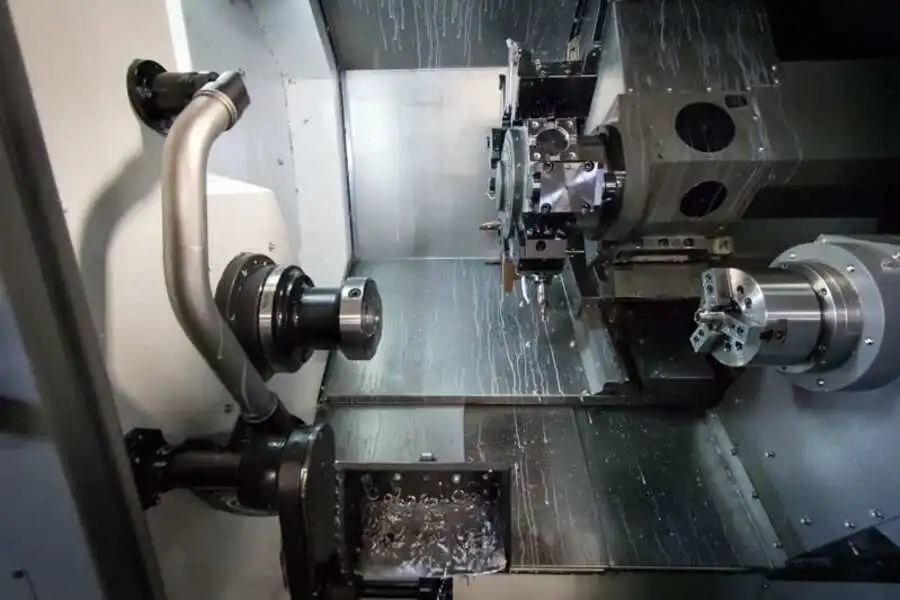

Izikhungo eziguqukayo ziyimishini esezingeni eliphezulu elawulwa ngezinombolo (CNC) yemisebenzi ehlukahlukene yezimboni. Ngokuvamile banezimbazo ezingu-3-5 namandla okusika amaningi, okuhlanganisa ukuphenduka, ukugaya, ukubhola, nokuthepha.

Kunezinhlobo ezimbili eziyinhloko zemishini yokujika, enezingqimba neqondile.

1) Izikhungo zokujika ezivundlile

Izikhungo zokujika ezivundlile iyimishini yokujika evame kakhulu kuzo zonke izimboni ezahlukene. Zibonakala ngokuphotha okuqondile okuqondile kanye nesibambi samathuluzi esisetshenziselwa ukukhweza amathuluzi okusika.

Izici

- I-spindle eqondile eqondile

- Ukunyakaza kwe-eksisi X kanye no-Z

- Ithuluzi turrets

- Amakhono okwenza ama-multi-axis, afana namathuluzi abukhoma kanye nokunyakaza kwe-Y-axis

- Izinhlelo zokulawula ze-CNC

- I-tailstock eguquguqukayo

buhle

- Ukuzinza okuhle kakhulu nokuqina, okuholela ekunembeni okuthuthukisiwe nokuqedwa kwendawo

- Imishini ye-Multi-axis, esiza ukwandisa ububanzi bemisebenzi

- Ukuqedwa kwendawo okuthuthukisiwe

- Ukwanda kokukhiqiza nokusebenza kahle

bawo

- Imishini yokujika evundlile inezinyathelo ezinkulu kunezindawo zokujika eziqondile, ngaleyo ndlela idinga indawo yaphansi eyengeziwe.

- Ukufinyeleleka okunomkhawulo kanye nokusebenziseka kalula

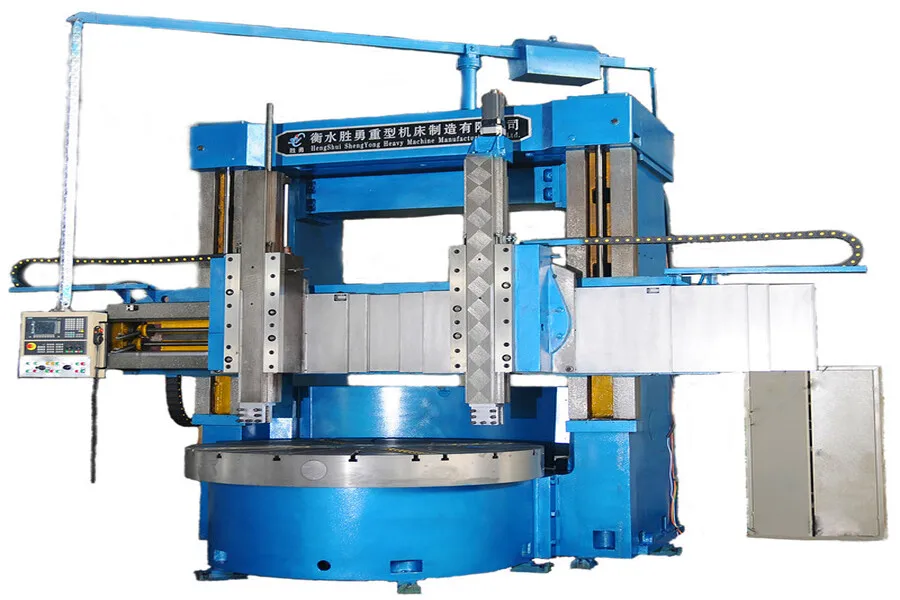

2) Izikhungo zokujika eziqondile

Izikhungo zokujika eziqondile zungezisa ucezu lokusebenza ku-eksisi eqondile. Le mishini ilungele ukukhiqiza izingxenye ezimfushane ezingadingi i-sub-spindle, tailstock noma i-turret engezansi.

Izici

- Ukuma kokuphotha okuqondile

- Ukushintsha kwethuluzi okuzenzakalelayo (ATC)

- I-interface ye-Turret

- Izikhungo zokujika eziqondile ezinkulu zingakwazi ukuphatha izingxenye ezinobubanzi obufika ku-300–800 mm (11.81–31.50 amayintshi)

- Izintambo zokuqoqa zilungele izingxenye ezinobubanzi obufika ku-300 mm ububanzi (amayintshi angu-11.81)

- Amasistimu e-CNC

- Imishini ye-Multi-axis

buhle

- Imishini nokuhlanganisa okusizwa amandla adonsela phansi, okuthuthukisa ukuzinza, ukuqina, nokunemba

- Ngokuvamile zinendawo encane kunezindawo zokujika ezivundlile, okwandisa ukusebenza kahle kwesikhala

- Umshini we-Multi-axis uwenza asebenze emisebenzini ehlukahlukene

bawo

- Ayifanelekile kuma-workpiece amade

- Izindleko eziphakeme zokuqala zokutshala imali uma kuqhathaniswa namathuluzi alula okwenza imishini

Lathi

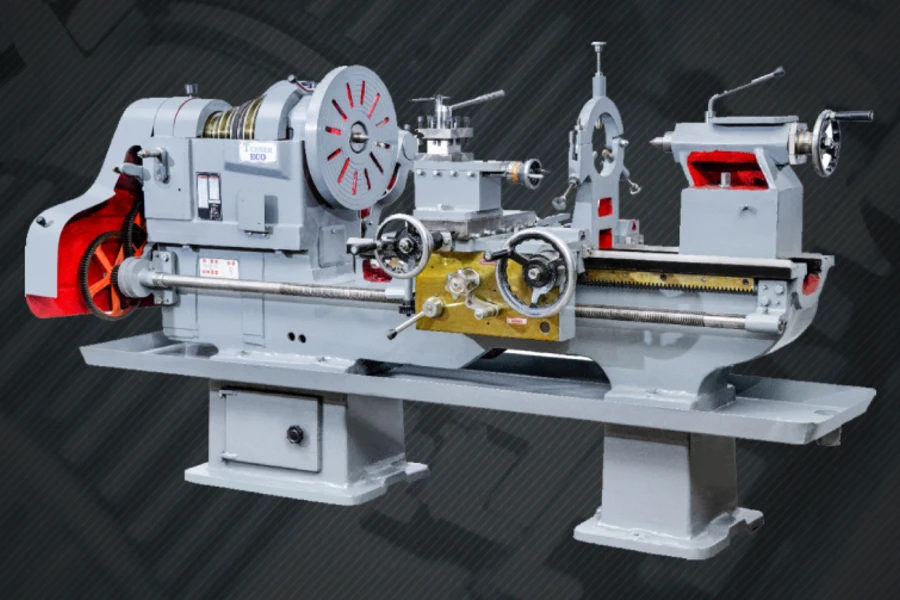

Ama-lathes ayimishini enezinjongo eziningi esetshenziswa ekukhiqizeni nasekulungiseni imisebenzi efana nokubumba, ukusika, ukujika, ukubheka, ukubhoboza, ukugoba, nokuhlanganisa. Izibonelo zezinhlobo ezahlukene zamalathe emakethe zifaka:

1) CNC lathe umshini

The Imishini ye-lathe ye-CNC babe nezici ezifanayo njengama-lathes okwenziwa ngesandla, okuhlanganisa i-spindle, i-headstock, i-chuck, i-tailstock, i-turret yamathuluzi kanye nezikhungo. Nokho, banengxenye eyengeziwe yephaneli yokulawula ye-CNC esetshenziselwa ukuqhuba izinhlelo nokunikeza imiyalelo yokufaka.

Izici

- Isistimu yokulawula ye-CNC

- Ukushintsha ithuluzi okuzenzakalelayo (ATC)

- I-tailstock ehlelekayo

- Amathuluzi abukhoma

buhle

- Ukuqapha okungaphakathi kwenqubo nokulawulwa kwekhwalithi okwenziwa izinhlelo zokulawula ze-CNC

- Ukunemba okuphezulu nokusebenza kahle

- Isikhathi sokusetha esincishisiwe

- Ilungele ukukhiqizwa ngobuningi

bawo

- Idinga ulwazi olukhethekile nokuqeqeshwa

- Ukuvumelana nezimo okukhawulelwe kokukhiqizwa kwenqwaba encane

- Idinga ukunakekelwa nokulungiswa njalo, okuholela ekunciphiseni isikhathi eside

2) Umshini we-lathe webhentshi

Imishini ye-lathe yebhentshi amalebula ahlangene futhi anosayizi omncane aklanyelwe ukusetshenziswa ebhentshini lokusebenza noma etafuleni. Ngokuvamile zisetshenziselwa izingcezu zokusebenza ezincane noma izinhlelo zokusebenza ezilula, okuzenza zifanelekele abathanda ukuzilibazisa, ama-workshop amancane, noma izilungiselelo zemfundo.

Izici

- Ukulawula isivinini esilungisekayo

- Okulula futhi okuphathekayo

- I-tailstock elungisekayo kanye nokuphumula kwamathuluzi

- Amanye ama-lathes ebhentshi anikeza osayizi abahlukahlukene be-chuck.

buhle

- Ilungele ama-workshops anendawo elinganiselwe

- Ingenza imisebenzi eminingi naphezu kosayizi wayo omncane

- Kuyathengeka uma kuqhathaniswa namanye amalathe ezimboni

bawo

- Ayifanele umsebenzi osindayo noma izinto zokusebenza ezinkulu.

- Amandla amancane nokuqina ngenxa yobukhulu bazo obuncane, obuthinta ikhono labo lokusingatha amaphrojekthi okusika anzima

3) Umshini we-lathe ozenzakalelayo

Automatic imishini yokugeza zingamathuluzi emishini athuthukisiwe aklanyelwe ukukhiqizwa okuzenzakalelayo kwezingxenye eziphendukile ngesivinini esikhulu. Lezi kakhulu imishini ye-lathe ezenzakalelayo ingakwazi ukwenza imisebenzi yomshini ngaphandle kokungenelela okwenziwa ngesandla njalo.

Izici

- Ifakwe izici ezithuthukisiwe ezizenzakalelayo

- Ihambisa imishini enesivinini esikhulu, ivumela imijikelezo yokukhiqiza esheshayo kanye nokwanda kokukhiqiza

- Izinhlelo zokulawula ze-CNC

- Ama-spindles amaningi kanye namathuluzi

- Ukukhishwa kwengxenye okuzenzakalelayo kanye nezinhlelo zokuhlunga

buhle

- Ukuguquguquka okuphezulu nokukhiqiza

- Inqubo yokwenza imishini ezenzakalelayo inciphisa izindleko zabasebenzi

- Amasistimu okulawula athuthukile nokwakhiwa komshini oqinile okwandisa ukunemba nokunemba

- Ifanele ukukhiqizwa ngobuningi

bawo

- Uhlelo oluyinkimbinkimbi nokusetha okungadinga ulwazi olukhethekile nokuqeqeshwa

- Ayilungele amaphrojekthi afaka izingxenye ezinkulu noma ezisindayo

4) Umshini we-Capstan/turret lathe

I-Turret lathes, eyaziwa nangokuthi i-capstan lathes, ziwuhlobo lomshini we-lathe ohlanganisa i-turret noma isiteshi samathuluzi. Le mishini yaziwa ngezinguquko zayo zamathuluzi ezisheshayo, ezivumela ukusebenza kwemishini esheshayo nephumelelayo.

Izici

- Isiteshi se-Turret noma samathuluzi

- Indlela yokwenza inkomba yokuma okunembile kwe-turret

- Ukuphakela okuzenzakalelayo nokuphatha impahla

- Ivumela izindawo eziningi zamathuluzi ku-turret, ngaleyo ndlela isuse isidingo soshintsho lwethuluzi okwenziwa ngesandla.

buhle

- Izinga eliphezulu lokukhiqiza

- Ukuma kwethuluzi okunembile, okuthuthukisa ukunemba nokuvumelana

- Ukuzenzakalela kunciphisa izindleko zabasebenzi

- Izinguquko zamathuluzi ezisheshayo nezisebenzayo

bawo

- Ayilungele imisebenzi yemishini eyinkimbinkimbi edinga amathuluzi akhethekile noma ukunyakaza kwama-eksisi amaningi

- Inani elilinganiselwe lamathuluzi ku-turret

Izikhungo eziphendukayo uma ziqhathaniswa nama-lathes: uyini umehluko?

Ngaphandle kokusetshenziswa kwazo ezindimeni ezedlulanayo, izikhungo zokujika kanye nezintambo zinezici ezihlukene namandla okusebenza. Lesi sigaba sihlola umehluko wabo omkhulu.

Umklamo womshini

Izikhungo eziphendukayo kanye nezintambo zinemiklamo ehlukahlukene yemishini, enquma ukusetshenziswa kwazo nokusebenza kwazo. Isibonelo, izindawo zokujika zinezindawo ezivalekile zemishini egcwele futhi zinokucushwa “kombhede otshekile” uma kuqhathaniswa nomklamo “we-flatbed” wamalathe.

Izikhungo eziphendukayo zinezici ezengeziwe ezifana namathuluzi abukhoma nama-turrets amathuluzi angabamba ukuphenduka, ukubhola, namathuluzi okugaya. Ama-lathes, ngokuphambene, anohlelo olulula lwamathuluzi futhi ngokuvamile aklanywa njengemishini ye-axis emibili, egxile kakhulu ekusebenzeni kokuvula.

Amakhono e-RPM

Amakhono e-RPM kuyo yomibili le mishini athonywa izici eziningi, njengamandla emishini kanye nomklamo, uhlobo nosayizi wesiqeshana somsebenzi, amathuluzi okusika asetshenzisiwe, nezinto ezenziwe ngomshini.

Izikhungo zokujika ze-CNC zinamandla aphezulu e-RPM kunama-lathes ngenxa yezinketho ezibanzi zesivinini sokuphotha. Ezikhungweni zokujika ze-CNC, isivinini se-RPM singasukela kokuphansi kokuthungatha kanye nokusebenza kwemishini esindayo kuye kusivinini esikhulu sokuqeda kahle nokusika ngesivinini esikhulu.

Izinga lokukhiqiza kanye ne-prototyping

Ama-lathes afaneleka kakhulu ekugijimeni kokukhiqiza okufushane, ukulungiswa okusheshayo, nezingxenye ezilula njengezikhonkwane nama-bushings. Ayashesha ukusetha nokusebenzisa, kokubili ngesandla kanye nezinhlelo ze-CNC.

Izikhungo eziguqukayo zifaneleka kakhulu ukukhiqiza okukhulu njengoba zinamandla amakhulu kanye nekhono lokukhiqiza. Bangenza imisebenzi eminingi ezenzakalelayo ngenani eliphakeme kunama-lathes. Izikhungo eziguqukayo zibonakala ngokuphakela izinto okuzenzakalelayo kanye namathuluzi ashintsha phakathi kwemijikelezo ehleliwe ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza.

Izindleko

Izikhungo zokujika zibiza kakhulu kunezintambo njengoba zinezici eziningi namandla. Le mishini yakhelwe ukuphatha uhla olubanzi lwemisebenzi yomshini, njengokujika, ukugaya, ukubhola, nokunye. Ngenxa yalokho, ngokuvamile ahlome ngezinto ezithuthukisiwe ukuze afake amakhono e-multi-eksisi, ukusebenzisa amathuluzi abukhoma, ama-sub-spindles, nezici ezishintshayo ezithuthukisiwe, okuzenza zibize kakhulu.

Ukuma kwezingxenye ezicutshunguliwe

Ama-Lathes asetshenziswa ngokuyinhloko ekucubunguleni ubujamo obuyi-cylindrical njengamasilinda, ama-cones, nama-sphere. Kodwa-ke, banamakhono alinganiselwe wejometri eyinkimbinkimbi kanye nokusebenza kwemishini yesibili.

Ngakolunye uhlangothi, imishini yokuphendula ingakwazi ukuphatha uhla olubanzi lwezingxenye zomumo namajiyometri. Bangakwazi ukucubungula izimo ze-cylindrical, ezifana nama-shaft, ama-rods, amashubhu, amakhonsathi, amaphrofayili, kanye nezici ezidinga imisebenzi yesibili njengokugaya nokubhoboza.

Isiphetho

Ukukhetha phakathi kwezikhungo zokuvula kanye nama-lathes kuncike emiphumeleni oyifunayo kanye nohlobo lwephrojekthi. Isibonelo, izikhungo zokuguqula zifaneleka kakhulu ekukhiqizeni okukhulu, kanti ama-lathes afaneleka kakhulu kumaphrojekthi wesikhashana. Ngakho-ke, amaklayenti azoba nezidingo ezihlukene futhi akhethe izikhungo zokujika ezihlukene noma ama-lathes ngokusekelwe kububanzi bezidingo namaphrojekthi awo.

Kubalulekile ukuthi amabhizinisi aqondise embonini yemishini abe nempahla ehlukahlukene. Vula amandla ebhizinisi lakho nge-Cutting-Edge izikhungo eziphendukayo futhi izihlakala iyatholakala ku-Cooig.com namuhla!