Emkhakheni wokuphrinta kwe-3D, amaphrinta e-resin 3D avele njengetshe legumbi lokunemba nekhwalithi, ahlinzekela uhla olubanzi lwezinhlelo zokusebenza kusukela ku-prototyping kuya ekukhiqizweni komkhiqizo wokugcina. Lesi sihloko sidingida ubunkimbinkimbi bokuphrinta kwe-resin 3D, ukuhlola amakhono obuchwepheshe, izinzuzo, kanye nokucatshangelwa abasebenzisi okufanele bakucabangele ngaphambi kokungena emanzini. Ngokuhlukanisa imiqondo eyinkimbinkimbi ibe izincazelo ezigayekayo, sihlose ukunikeza ukuqonda okuphelele kwamaphrinta e-resin 3D, ukukunikeza amandla olwazi ukuze usebenzise lobu buchwepheshe ngempumelelo.

Okuqukethwe:

- Ukuqonda ubuchwepheshe bokuphrinta be-3D resin

- Izinzuzo zokusebenzisa iphrinta ye-resin 3D

- Izicelo ezijwayelekile zamaphrinta we-resin 3D

- Ukucatshangelwa okubalulekile ngaphambi kokuthenga

– Amathiphu okunakekela nokuphepha

Ukuqonda ubuchwepheshe bokuphrinta be-resin 3D

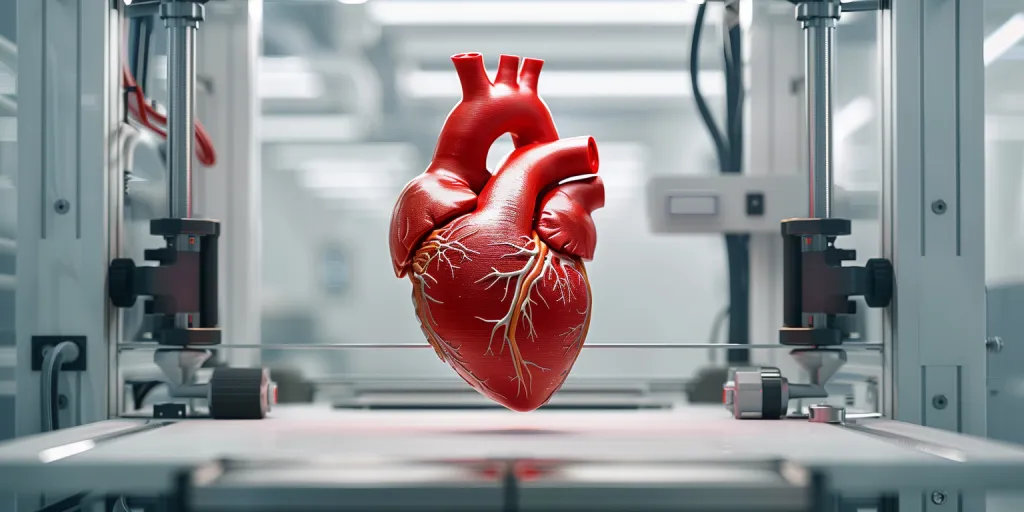

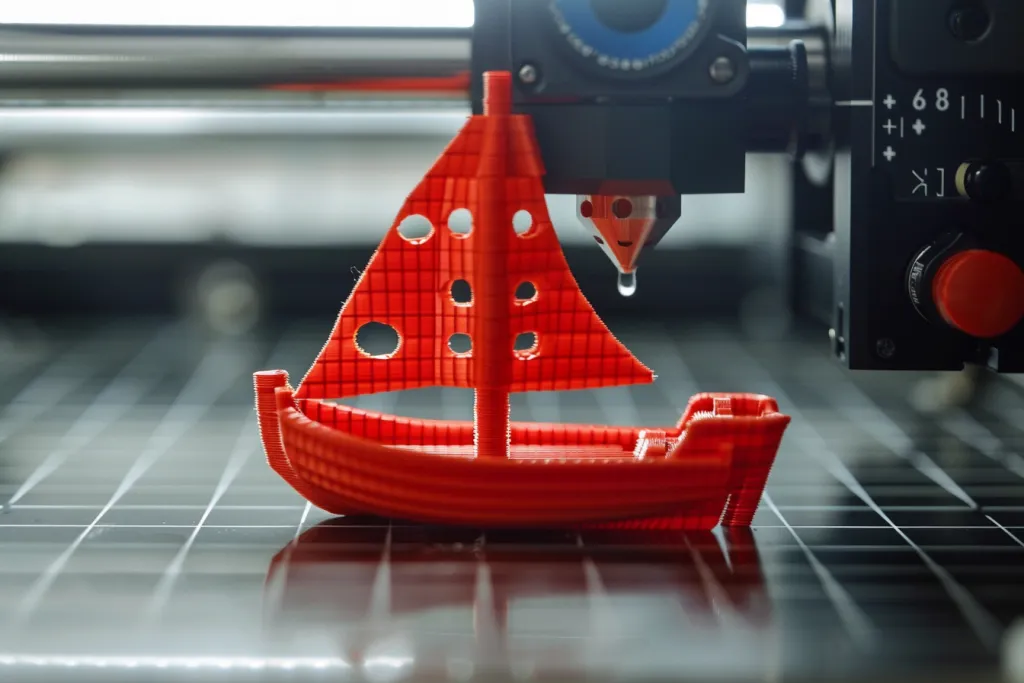

Ukuphrinta kwe-Resin 3D, eyaziwa nangokuthi i-Stereolithography (SLA), igqama ngekhono layo lokukhiqiza izinto ezinokulungiswa okuphezulu nokunemba ngendlela emangalisayo. Inqubo ihilela ukuphulukisa inhlaka ye-photopolymer ewuketshezi ibe izinto eziqinile, ungqimba ngongqimba, kusetshenziswa ukukhanya kwe-ultraviolet (UV). Le ndlela ivumela imininingwane eyinkimbinkimbi kanye nokuqedwa okushelelayo okuvame ukuba yinselele ukufeza nezinye izinhlobo zobuchwepheshe bokuphrinta be-3D.

Umnyombo wobuchwepheshe bokuphrinta be-resin 3D ukunemba kwawo. Ilaser ye-UV igxile emaphoyintini athile ku-resin vat, iqinisa inhlaka lapho into ezokwakhiwa khona. Leli zinga lokulawula livumela ukudalwa kwamajiyometri ayinkimbinkimbi, imiphetho ebukhali, nezici ezinhle ezibalulekile ezinhlelweni eziningi zokusebenza zobungcweti nezimboni.

Nokho, ukuqonda ukulinganiselwa kubalulekile. Ukusetshenziswa kwe-resin njengento edingekayo kudinga ukuphathwa ngendlela efanele kanye nokungena komoya ngenxa yezakhiwo zayo zamakhemikhali. Ukwengeza, izakhiwo zokusekela ezidingekayo kuma-overhangs nama-undercuts zingashiya amamaki adinga ukucutshungulwa ngemuva. Ngaphandle kwalokhu kucatshangelwa, izinzuzo zokuphrinta kwe-resin 3D ekukhiqizeni izingxenye ezisezingeni eliphezulu kuyenza ibe ithuluzi elibalulekile emikhakheni ehlukahlukene.

Izinzuzo zokusebenzisa iphrinta ye-resin 3D

Enye yezinzuzo ezibaluleke kakhulu zamaphrinta we-resin 3D ukuqeda kwawo okuphezulu. Izinto eziphrintwe nge-resin zibonisa izindawo ezibushelelezi nezinga lemininingwane engenakuqhathaniswa namaphrinta e-3D asuselwa ku-filament. Lokhu kwenza ukuphrinta kwe-resin kukhange ikakhulukazi ezinhlelweni lapho ikhwalithi yobuhle ibaluleke kakhulu.

Enye inzuzo ijubane lokuphrinta. Nakuba kuncike enkingeni nakusayizi wokuphrinta, amaphrinta e-resin ngokuvamile angaqeda imisebenzi ngokushesha kunozakwabo be-filament. Lokhu kusebenza kahle kungenxa yemvelo yenqubo yokwelapha, engaqinisa zonke izendlalelo ngesikhathi esisodwa, kunokuba ilandelele iphuzu lesendlalelo ngasinye ngephuzu.

Ngaphezu kwalokho, ukuhlukahluka kwezinto ze-resin kuvumela ukusetshenziswa okubanzi. Ukusuka kokuqinile nokuqina kuya kokuguquguqukayo nokusobala, ububanzi bezinhlaka ezitholakalayo zisho ukuthi abasebenzisi bangakhetha izakhiwo ezifanelekile zephrojekthi ngezidingo zabo ezithile zephrojekthi. Lokhu kuvumelana nezimo kuvula amathuba amasha emikhakheni efana namazinyo, ubucwebe, kanye nokukhiqizwa kwe-prototype.

Izicelo ezijwayelekile zamaphrinta we-resin 3D

Amaphrinta we-Resin 3D athole i-niche ezimbonini ezisa ukunemba nemininingwane ngaphezu kwakho konke. Embonini yamazinyo, ngokwesibonelo, odokotela basebenzisa ukuphrinta kwe-resin ukuze benze amamodeli wamazinyo anembe kakhulu nezinto ezisetshenziswa ngokwezifiso. Ikhono lokukhiqiza lezi zinto endlini lishintsha ukunakekelwa kwesiguli ngokunciphisa izikhathi zokulinda nokuthuthukisa ukwenza ngokwezifiso.

Emkhakheni wokwenziwa kobucwebe, amaphrinta e-resin 3D anika amandla abaklami ukuthi bakhe amaphethini ayinkimbinkimbi kanye nokubunjwa okwakungenakwenzeka ngaphambilini noma okumba eqolo. Lobu buchwepheshe buvumela inqubo yokuklama, buvumele ukwenziwa kwe-prototyping ngokushesha kanye nokuhlola ngengxenye yezindleko zezindlela zendabuko.

Ngaphezu kwalokho, umkhakha wezemfundo uzuza kumaphrinta e-resin 3D ngokunikeza abafundi ukufinyelela kumamodeli wekhwalithi ephezulu wokufunda nokucwaninga. Kungakhathaliseki ukuthi ku-biology, engineering, noma ubuciko, umuzwa othintekayo wokubamba imodeli enemininingwane kuthuthukisa ukufunda nokudala.

Ukucatshangelwa okubalulekile ngaphambi kokuthenga

Ukutshala imali kuphrinta ye-3D resin kudinga ukucatshangelwa ngokucophelela kwezinto ezimbalwa. Okokuqala, izindleko zokuqala kanye nezindleko eziqhubekayo zezinto zokwakha nokugcinwa kwazo zingabaluleka. Abathengi abazoba ngabathengi kufanele bahlole ibhajethi yabo kanye nembuyiselo engaba khona ekutshalweni kwe-resin engayiletha kumaphrojekthi noma ibhizinisi labo.

Okwesibili, ijika lokufunda lokusebenzisa iphrinta ye-3D ye-resin kanye nokuphrinta kwangemuva kokucubungula kungaba umqansa kwabaqalayo. Nakuba ubuchwepheshe buya kuba busebenziseka kalula, ukuzuza imiphumela emihle kuvame ukudinga ukuhlolwa nolwazi.

Okokugcina, izici zokuphepha nezemvelo ngeke zinganakwa. Ukuphatha i-resin ewuketshezi kanye nokubhekana namakhemikhali angemuva kokucubungula kudinga okokusebenza okufanele kokuphepha kanye nokukhipha umoya. Abasebenzisi kufanele bazijwayeze nezinqubo ezingcono kakhulu zokuqinisekisa ukusebenza okuphephile nokuqhubekayo.

Amathiphu okunakekela nokuphepha

Ukugcina iphrinta ye-3D ye-resin kubalulekile ekuqinisekiseni ubude bayo nokusebenza kwayo. Ukuhlanza njalo i-vat ye-resin, ukuhlola umthombo wokukhanya we-UV, nokubuyekeza i-firmware yephrinta konke kuyizinyathelo ezibalulekile. Ukwengeza, ukuhlunga nokugcina kahle i-resin engasetshenziswanga kungavimbela ukungcoliswa nokumosha.

Ukuphepha kubaluleke kakhulu uma usebenza namaphrinta e-resin. Ukusebenzisa amagilavu, imaski, nezingubo zamehlo ezivikelayo kunganciphisa ukuchayeka kumakhemikhali angaba yingozi. Ngaphezu kwalokho, ukusebenza endaweni enomoya omuhle noma ukusebenzisa uhlelo lokuhlunga umoya kusiza ukugcina indawo enempilo.

Isiphetho

Amaphrinta we-Resin 3D anikezela ngokunemba okungenakuqhathaniswa, isivinini, nokuguquguquka, okuwenza abe yithuluzi eliyigugu kuzo zonke izimboni ezihlukahlukene. Ngokuqonda ubuchwepheshe, ukusetshenziswa kwabo, kanye nokucatshangelwa okuhilelekile, abasebenzisi bangasebenzisa amandla aphelele okuphrinta inhlaka. Ngendlela efanele yokunakekela nokuphepha, ukuphrinta kwe-resin 3D kungavula ama-horizons amasha ekukhiqizeni, ekuklameni, nasemfundweni, kudlule imingcele yalokho okungenzeka.