Imishini yokusika i-Laser ingabonakala njengesibonelo sokuphelela uma kuziwa kunoma yimuphi umshini ngoba inikeza ukunemba, isivinini kanye nokuguquguquka kwezinto zokusika ngokungafani nanoma yimuphi omunye umshini emhlabeni. Lo mhlahlandlela uchaza ukuthi abasiki be-laser basebenza kanjani, basetshenziswa kanjani, nokuthi kubiza malini, kanye nokubheka abasiki be-laser abasezingeni eliphezulu abatholakala emakethe.

Okuqukethwe:

- Uyini umshini wokusika i-laser?

- Isebenza kanjani imishini yokusika i-laser?

- Ungawusebenzisa kanjani umshini wokusika i-laser

- Ubiza malini umshini wokusika i-laser?

- Imishini yokusika i-laser ephezulu

Uyini umshini wokusika i-laser?

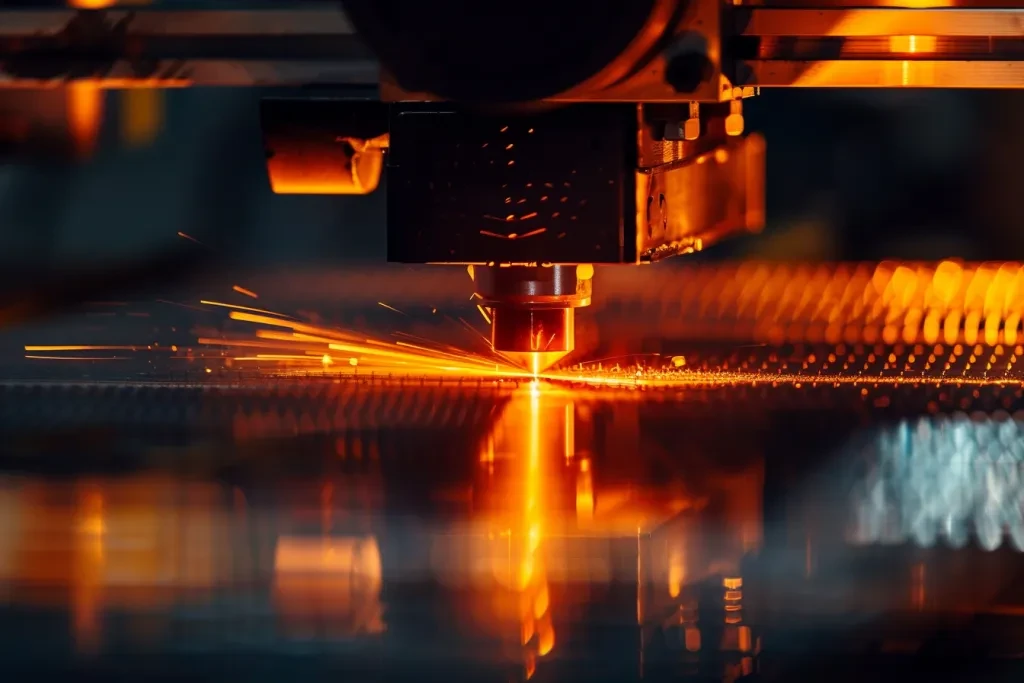

Umshini wokusika i-laser iyisisetshenziswa esithuthukisiwe sikagesi esisebenza nge-laser beam. Yenzelwe ukusika, ukuqopha, noma ukumaka endaweni. Imishini yokusika i-laser esetshenziswa ezimbonini eziningi ngenxa yokunemba nokusebenza kahle kwayo. Ukusika, ukuqopha nokumaka ezintweni ezihlukahlukene sekulula kakhulu kusetshenziswa imishini yokusika i-laser .Imishini yokusika i-laser ingasetshenziswa ezinhlobonhlobo ezinkulu zezinto ezihlanganisa insimbi, ipulasitiki, ukhuni nengilazi. Ubuchwepheshe bokusika i-laser buye bavela ngokuhamba kwesikhathi okwenza kube nemishini yokusika i-laser.

Umsiki we-laser udlulisela amandla ezintweni kusetshenziswa umsebe wokukhanya ogxilile. Ukukhanya kufinyelela umgomo wako, futhi amandla amuncwa izinto, okubangela ukuncibilika kokuqala, ukushiswa noma ukuhwamuka, futhi ekugcineni kusike phakathi kwezinto. Konke kwenzeka endaweni ekude, efana ne-vacuum ngaphandle kokuxhumana. Izimo ezinjalo ezilawulwa kakhulu zinamandla okukhiqiza amaphethini ayinkimbinkimbi anemininingwane emihle kakhulu, okuholela ekulahlekeni okuncane. Ukhiye lapha ukusika okukude, ngaphandle kokuthinta. Izinto ezisetshenziswayo zingasetshenziswa ngokuphepha entweni ngokusebenzisa amandla e-laser, futhi inkinga yokungcoliswa iba yimbi.

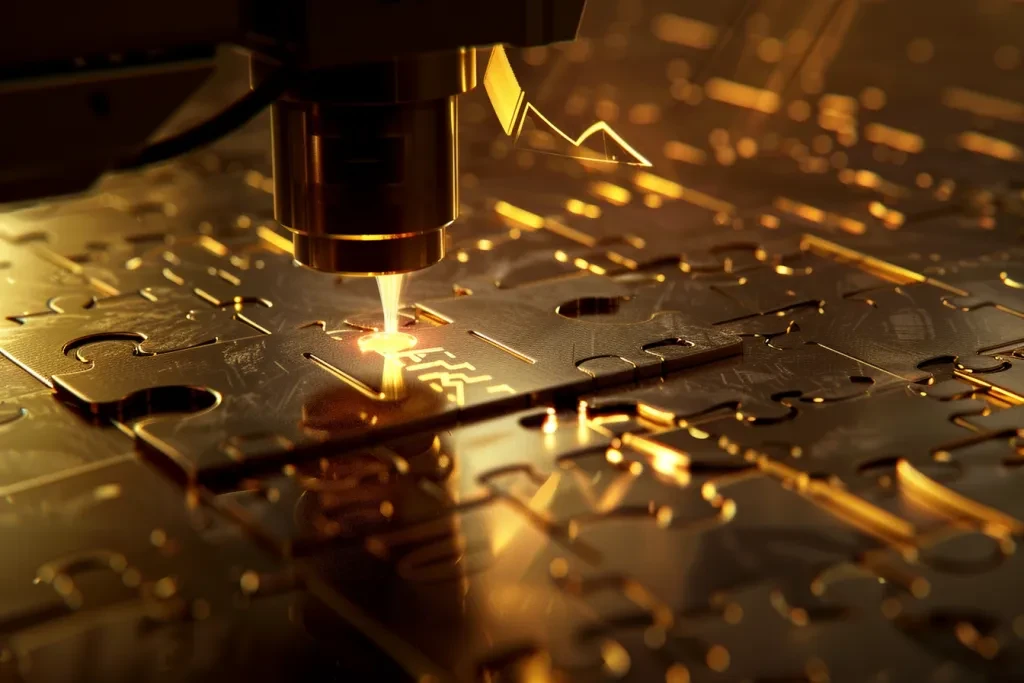

Ukuhlukahluka kwe-laser cutter kuyenza ikwazi ukuqopha noma iqophe iphethini noma idizayini endaweni engaphezulu yento kunokumane iyisike. Kulelo phuzu, umklami noma omunye umuntu onobuciko bobuciko angakwazi ukudweba kalula noma ukuphothula idizayini nganoma iyiphi i-graphics noma isofthiwe yokuklama futhi adlulisele umklamo kokubalulekile.

Isebenza kanjani imishini yokusika i-laser?

Ingxenye yayo eyinhloko i-laser ekhiqizwe ngeshubhu le-laser eligcwele igesi noma imidiya yesimo esiqinile. Lapho i-current isetshenziswa ku-laser tube, ikhiqiza i-beam yokukhanya okuhambisanayo. Izibuko eziningi zisiza inqubo yokukhiqiza futhi ekugcineni ukukhanya kugxilwe endaweni enhle nge-lens egxilile. I-beam egxilile isuke iqhunyiswa kokubalulekile ukwethula ukushisa okukhulu namandla.

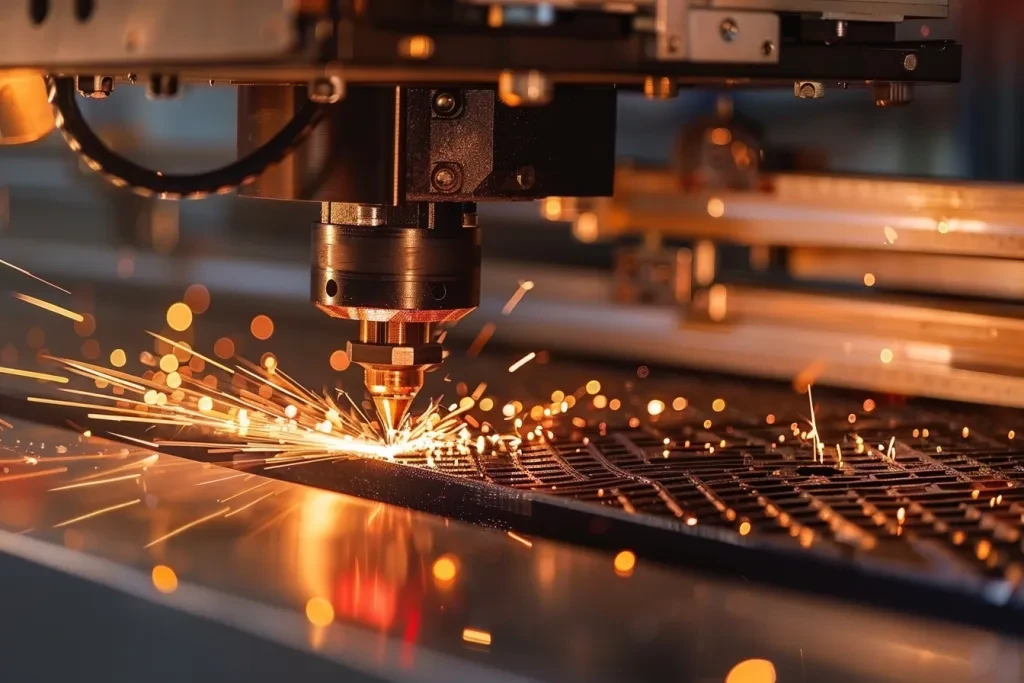

Ikhompyutha ilawula umugqa wokusika we-laser beam ngokuya ngemidwebo yedijithali noma amaphethini - uhlelo lokulawula izinombolo lwekhompiyutha (CNC) - olungahambisa umugqa wokusika uye kuma-fractions anembile wemilimitha, futhi ingakwazi ukusika ngesivinini namazinga wamandla ancike ezintweni kanye nomphumela. Ama-Laser cutters ahlukahlukene ngendlela emangalisayo.

Isistimu yokupholisa nayo iyadingeka ukuze isuse ukushisa, ngaphandle kwalokho idivayisi ivele iyeke ukusebenza. Amasistimu asekelwe emanzini asetshenziselwa amandla okusika aphezulu, kuyilapho ukupholisa komoya kuvame kakhulu emandleni aphansi e-laser. Ukugcinwa okufanele kwalezi zakhi kanye nokulinganisa kwe-laser, izingxenye ze-optical kanye nemishini yomshini kuyadingeka ukuze kuqinisekiswe impilo ende ye-laser cutter kanye nezingxenye zayo.

Ungawusebenzisa kanjani umshini wokusika i-laser

Ukulungiselela ukuqalisa umshini wokusika i-laser kudinga ukuthi umklamo ulungele. Lokhu ngokuvamile uhlobo oluthile lwesithombe oluchazwe kuhlelo olukhethekile. Lolo hlelo luzoguqula izithombe zedijithali zibe ulimi umshini we-laser ongaluqonda. Uma isilayishiwe, isofthiwe izotshela isignali ye-laser ukuthi ilandelwa nini, kuphi, futhi kanjani imingcele enqunywe kusengaphambili yomklamo.

Ukulungiselela impahla efanele nakho kuyadingeka. Impahla ezosikwa kumele iboshwe ngokuqinile embhedeni wokusika ukuze inganyakazi ngenkathi isikwa. Izinto ezisetshenziswayo ezihlukene zinezindlela zokupheka ezihlukene, njengamandla, isivinini nokugxila, ukuze ziveze imiphumela emihle. Ngokuvamile, iresiphi kufanele itholwe ngokuzama nangephutha noma ngokubheka ukulungiselelwa kwezinto ezibonakalayo ezinikezwe umenzi womshini.

Ukuqinisekisa ukuphepha kwabasebenzi kuyinto ehamba phambili uma usebenzisa ama-laser cutters; opharetha kufanele bahlale begqoke izingubo zamehlo ezivikelayo ukuze bavimbe imisebe ye-laser eyingozi futhi banciphise izingozi zomlilo njengoba i-laser beam ingafinyelela amazinga okushisa ezigidi zamadigri celsius. Isistimu yokungenisa umoya egcinwe endaweni yokusika nayo ibalulekile, njengoba ukusika kungakhipha kalula intuthu nentuthu eyingozi kubantu.

Ubiza malini umshini wokusika i-laser?

Inani le-laser cutter lingahluka ngokuya ngosayizi, inani lamandla eliwasebenzisayo, nezici ezifakiwe. Kuye ngomshini, ungaqala kusukela kumakhulu ambalwa amadola emshinini omncane osezingeni lokungena kuze kufike emashumini ezinkulungwane zamaRandi njengoba eminye imishini esetshenziswa ezimbonini yakhelwe ukusetshenziswa kochwepheshe nokusindayo.

Intengo incike ohlotsheni lwe-laser (i-CO2 laser, i-fiber laser, i-crystal laser), amandla e-laser (watt), usayizi wombhede wokusika kanye nenani lezici ezengeziwe (ezifana ne-autofocus, isistimu yokupholisa ehlanganisiwe, isofthiwe ethuthukisiwe). Lapho utshalomali oluphezulu emishinini yekhwalithi, imiphumela iba ngcono, ukwethembeka okuphezulu kanye nezindleko zokunakekela eziphansi.

Umsiki wezimpawu we-laser ungasiza ibhizinisi ukuthi likhulise umkhiqizo futhi lithuthukise amakhono, kodwa izindleko zempahla efakwe kulokho kutshalwa kwezimali kufanele zicatshangelwe ngokucophelela. Amabhizinisi angathola izinketho zokuxhasa ngezimali ngisho nokuqashisa ukuze anciphise izindleko zokuqala ze-laser cutter uma ukonga kudlula utshalomali lulonke.

Imishini yokusika i-laser ephezulu

Kunezinkampani ezimbalwa ezihamba phambili ezikhiqiza imishini emikhulu, ethembekile, yokusika i-laser. Owokuqala yi-Glowforge Plus, umshini oqondiswe kwabathanda ukuzilibazisa kanye namabhizinisi amancane. Lo mshini osebenzayo, oxhumanisayo futhi odlalayo - omunye odume kakhulu esake sakubona ngesofthiwe esekelwe emafini noma ubani angafinyelela kuyo ngocingo lwakhe - uguquguquka kakhulu futhi ungasika izinto ezihlukahlukene ezihlukahlukene. Uma udinga ikhwalithi ephezulu kakhulu, amandla ebanga lezimboni, uchungechunge lwe-Epilog Laser Fusion Pro luza namandla ebanga lezimboni, okuhlanganisa isivinini sokusika esisheshayo nezindawo zokusebenza ezinkulu.

Okunye ukungena yi-Dremel Digilab LC40, imodeli ethengekayo nethembekile elungele othisha, amabhizinisi amancane noma abathanda ukuzilibazisa okungathi sína. Inesofthiwe enembile kodwa enamandla oyidingayo ukuze uthole amaphrinti aphelele, kanye nezingxenye zekhwalithi ephezulu ezizoqinisekisa ukusebenza okuhle iminyaka eminingana.

Ngokusetshenziswa kwezimboni ngokwesiko, uchungechunge lwe-Trumpf TruLaser lunikeza ukusika ngesivinini esikhulu nokukhetha izinketho ezizenzakalelayo, kuyilapho futhi lunikeza ukunemba kwemilimitha, kuze kufike lapho kungenzeka khona ukusika insimbi ibe ukujiya kwemilimitha eyodwa kuphela. Kubasebenzi bensimbi abafuna ukuhlala, noma ukuya phambili, emqhudelwaneni ngamasu asezingeni eliphezulu okusika i-laser, u-Trumpf unemakethe ngempela.

Isiphetho: Imishini yokusika i-laser inamandla amakhulu okunemba, isivinini, kanye nokuguquguquka kwezinto ezihlukahlukene kanye nezinhlelo zokusebenza. Ukuqonda ukuthi ama-laser cutter asebenza kanjani, asetshenziswa kanjani, nokuthi zingakanani izindleko zokusika i-laser kungasiza amabhizinisi nabantu ngabanye benze izinqumo ezinolwazi mayelana nokuthi bazotshala nini futhi nini kulobo buchwepheshe. Ngomshini ofanele, abasebenzisi bangaba nomhlaba omusha wobuciko nokukhiqiza okuvulwe phambi kwabo.