Enhle ishidi lenhlama kwenza kube lula kubapheki ukwenza ama-pizza, ipasta, namakhekhe. Ukwanda kwesidingo samashidi enhlama embonini yokudla kanye namabhikawozi ezimboni kuholele ekutheni abadlali abaningi bajoyine imakethe. Ukutholakala kwamashidi amaningi enhlama evela kubakhiqizi abahlukene akusho ukukhetha umshini ofanele kuzoba lula; esikhundleni salokho, kuwubuqili ukukhomba ekahle.

Funda ukuze uthole izinhlobo ezahlukene zamashidi enhlama atholakalayo emakethe nokuthi ungawakhetha kanjani afanelekile. Lesi sihloko sizophinde sixoxe ngokuthi ama-dough sheeters asebenza kanjani kanye nesabelo nobukhulu bemakethe ye-dough sheeters.

Okuqukethwe

Isabelo kanye nosayizi wemakethe ye-dough sheeters

Asebenza kanjani amashidi enhlama

Izinhlobo zamashidi enhlama

Indlela yokukhetha amashidi enhlama afanelekile

Isifinyezo

Isabelo kanye nosayizi wemakethe ye-dough sheeters

Ukwenyuka kwesidingo sokudla okugayiwe kuyisici esikhulu esishayelayo amashidi enhlama ukuthengisa komhlaba wonke. Ngokuvamile, imakethe ye-dough sheeters ihlukaniswe ngokususelwa kuhlobo, isicelo, kanye nesifunda. Izinhlobo zifaka isitayela sebhentshi namashidi we-tabletop. Ngokusekelwe kuhlelo lokusebenza, izigaba ezithile amabhikawozi, izindawo zokudlela, nokunye.

Ubukhulu bemakethe ye-dough sheeters emhlabeni wonke bulinganiselwa ukuthi bunjalo I-USD 1.09 billion ngo-2021. Idatha ye-Intero kulindeleke ukuthi ikhule ifinyelele ku-2030 ngezinga lokukhula elihlanganisiwe lonyaka (CAGR) lika 3.3%. Ngokungeziwe ekwandeni kwesidingo semikhiqizo ye-confectionery kanye ne-bakery, ukukhula kuzobalelwa emalini ekhulayo elahlwayo kanye nenani labantu elikhulayo.

INorth America iphakathi kwezifunda okulindeleke ukuthi zibuse imakethe yamashidi enhlama emhlabeni wonke ngenxa yesidingo esikhulayo sokudla okubhakiwe. I-Europe izoba yimakethe yesibili ngobukhulu, ngenxa yesidingo esikhulayo samakhekhe nesinkwa. I-Asia Pacific izoba yimakethe ekhula ngokushesha ngenxa yokwanda kwenani lama-pizzeria namabhikawozi. Ezinye izinkampani ezinkulu ezihlotshaniswa nokukhiqizwa kwamashidi enhlama zihlanganisa i-Ferneto, i-Omcan, i-Fritsch, ne-Cavallini.

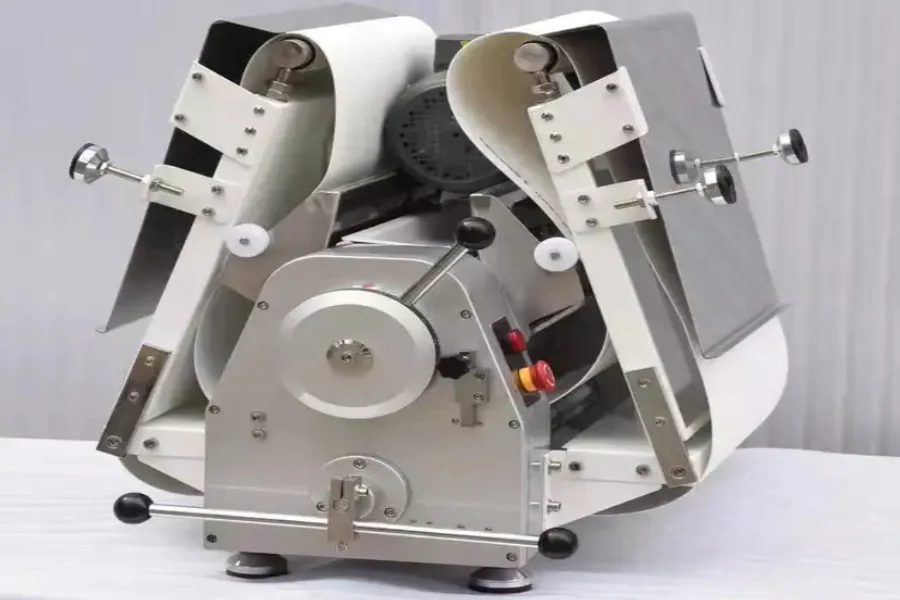

Asebenza kanjani amashidi enhlama

Amashidi enhlama adlulisa izigaxa zenhlama phakathi kwamarola amabili acaba futhi anwebe inhlama ibe ukujiya okungaguquki. Zenzelwe ukucubungula inhlama eningi ngokungaguquki futhi ngokushesha. Izinto ezisetshenziswayo zisetshenziselwa ukonga isikhathi namandla ezinqubweni zokwenza inhlama yezentengiselwano.

Ngezansi inqubo yesinyathelo ngesinyathelo sokuthi amashidi enhlama asebenza kanjani:

– Umsebenzisi ubeka ibhola lenhlama ebhandeni le-conveyor.

– Ibhola lenhlama libe selifakwa eqoqweni lokuqala lamarola ukuze acabangwe abe yisimo esingunxande.

– Inhlama eyisicaba idluliswa kolunye uchungechunge lwamarola anciphisa ngokuhlelekile ukujiya kwawo.

– Amarola ayalungiswa ukuze afinyelele ubukhulu obufunekayo, bese inhlama isikwa ibe ngosayizi oyifunayo womkhiqizo wokugcina.

– Ishidi lenhlama eliqediwe, selilungele ukusetshenzwa futhi, lidluliselwa ebhandeni lokuhambisa eliphuma ngaphandle.

Izinhlobo zamashidi enhlama

Kunamashidi enhlama ahlukahlukene, ngalinye lakhelwe ukusetshenziswa okuthile nezinhlobo zenhlama. Ngezansi izinhlobo ezivame kakhulu zamashidi enhlama:

1. Amashidi enhlama eyenziwe ngezandla

Ziwuhlobo olulula kakhulu lwe amashidi enhlama. Anama-roller amabili angashintshwa ngesandla ukuze aguqule ukushuba kwenhlama. Zincane futhi zilungele ukusebenza ngezinga elincane njengamabhikawozi amancane kanye nokubhaka ekhaya.

2. Amashidi enhlama e-semi-automatic

Amashidi enhlama e-semi-automatic zifana ncamashi nezishicileli zenhlama ezenziwe ngezandla kodwa zifakwe uhlelo oluzenzakalelayo lokuthutha oluphakela inhlama ibe amarola. Ayashesha, ngakho alungele ukusebenza okuphakathi nendawo.

3. Amashidi enhlama azenzakalelayo

Lezi ziwuhlobo oluthuthuke kakhulu lwe amashidi enhlama, njengoba ifakwe isistimu ezenzakalelayo ngokuphelele. Bangakwazi ukukhiqiza amashidi enhlama afanayo ngokushesha nangempumelelo. Ngakho-ke, asetshenziselwa imisebenzi emikhulu njengamabhikawozi okuhweba.

4. Amashidi enhlama e-Spiral

Bangamashidi enhlama akhethekile aklanyelwe ukukhiqiza inhlama ezwelayo futhi ethambile njengenhlama e-croissant, i-puff pastry, kanye ne-Danish. Basebenza ngobumnene ngokusonta inhlama ngochungechunge lwamarola, okunciphisa ubungozi bokulimaza inhlama futhi kulondoloze nesakhiwo sayo esintekenteke.

5. Lamination sheet sheets

Le mishini yakhelwe ukusetshenziswa nayo inhlama laminated njengenhlama ye-croissant. Bahlanganisa inhlama namafutha ndawonye bese bayakugoqa kube ukujiya okufanayo. Lokhu kusiza ukudala izendlalelo ezintekenteke eziyisici salezi zinhlobo zamakhekhe.

Indlela yokukhetha amashidi enhlama afanelekile

I-1. Ibhajethi

Abathengi kufanele baqaphele ukuthi izintengo zangempela zamashidi enhlama zincike kumkhiqizo, izici, namandla. Kufanele futhi bacabangele izidingo zabo zokukhiqiza nokuthi yini ehambisana nesabelomali sabo.

With I-USD 500 noma ngaphansi, abathengi bangathola amashidi enhlama enziwe ngesandla noma enziwe ngesandla, alungele amabhikawozi amancane. Uhla lwebhajethi ye USD 1,000-3,000 angathola amashidi enhlama asezingeni lokungena, alungele kakhudlwana futhi afanele amabhikawozi amancane naphakathi nendawo. Ngokwesilinganiso, ukuthenga amashidi enhlama kagesi asezingeni eliphezulu kungabiza ngaphezulu I-USD 3,000. Aklanyelwe amabhikawozi amakhulu futhi angakwazi ukuphatha inhlama eningi.

2. Amandla

Umthamo wabashicileli benhlama ukhombisa inani lenhlama abangayicubungula ngesikhathi esithile. Abathengi kufanele bacabangele ubukhulu bamakhishi abo noma amabhikawozi kanye nevolumu yenhlama abahlose ukuyicubungula.

Amashidi enhlama anezinga eliphansi afanele amabhikawozi amancane, amakhishi asekhaya, namakhefi. Ngokwesilinganiso banamandla okuba cishe Ama-50 amakhilogremu lenhlama ngehora. Amashidi enhlama aphakathi nendawo anomthamo cishe Ama-100 amakhilogremu lenhlama ngehora. Lezi zilungele amakhishi okuhweba aphakathi nendawo namabhikawozi. Inqubo yamashidi enhlama enezinga eliphezulu ngaphezu kwamakhilogremu ayi-100 lenhlama ngehora. Zenzelwe amabhikawozi amakhulu kanye amakhishi okuhweba ezidinga ukucutshungulwa kwenhlama enevolumu ephezulu.

I-3. Ikhwalithi

Abathengi banezici ezihlukahlukene okufanele bazicabangele mayelana nekhwalithi. Kubalulekile ukucabangela abakhiqizi, izinto zokwakha, kanye nezici ezengeziwe. Kunemikhiqizo enegama elihle lokukhiqiza amashidi enhlama ekhwalithi ephezulu. Ukuqina kwe-dough sheeter kuncike ezintweni ezisetshenziswa ekwakhiweni kwayo.

Isibonelo, amashidi enhlama enziwe ngensimbi engagqwali aqinile futhi kufanele agcinwe ukuze kuqinisekiswe impilo ende yesevisi. Futhi, abathengi kufanele bakhethe amashidi enhlama okulula ukuwasebenzisa futhi abe nezici zokuphepha njengezinkinobho zokumisa izimo eziphuthumayo.

4. Ukuguquguquka

Izinga lokulungiswa kwamashidi enhlama liyahlukahluka kakhulu. Ngakho-ke, abathengi kufanele bahlale bekhetha i-sheeter yenhlama ngokusekelwe ezidingweni zabo zokubhaka. Abashicileli benhlama abahlukahlukene banikeza uhla oluhlukile lokujiya kwenhlama ukuze kufakwe izindlela zokupheka ezahlukene nezinhlobo zenhlama.

Kukhona amashidi enhlama anezici zokulawula isivinini ezivumela abathengi ukuthi baqaphe isivinini sama-roller ukuze bakhiqize imiphumela enembayo. Ukwengeza, isikhala samarola, igebe, kanye nendawo kuzovumela abathengi ukuthi balawule ukushuba kanye nebanga ngesikhathi sokukhiqiza.

5. Noise

Lapho bekhetha amashidi enhlama asekelwe ezingeni lomsindo, abathengi kufanele bacabangele izinto ezisetshenziswa ekwakheni, isilinganiso se-decibel, kanye nekhwalithi yokwakha. Kufanele futhi bahlole ukuncishiswa komsindo kuzilungiselelo ezithile zemishini.

Ukucwaninga nokuhlola ukubuyekezwa kwamakhasimende kubalulekile ukuze uthole ulwazi olubalulekile kumazinga omsindo wamamodeli ahlukahlukene. Amanye amashidi enhlama enziwe ngezinto ezinciphisa umsindo nezibamba umsindo njengerabha.

6. Ukusebenza kahle

Ukusebenza kahle kuhilela ukutshala imali kumashidi enhlama asezingeni eliphezulu futhi aklanywe kahle. Le mishini ingacubungula inhlama ngokushesha nangempumelelo ngaphandle kwemfuneko encane noma ingabikho yokulungiswa noma isikhathi sokuphumula.

Amashidi enhlama anamandla okukhiqiza ahlangabezana nezidingo zabathengi afanelekile. Ukulawula isivinini nokuphatha inhlama kuvumela abathengi ukuthi bacubungule izinhlobo zenhlama nogqinsi ngendlela efanele. Ukwengeza, i-automation iqinisekisa ukusetshenziswa kalula, ngaleyo ndlela kusize ukwandisa ukuphepha nokusebenza kahle.

Isifinyezo

Ngaphezu kwezinto ezishiwo kumhlahlandlela ongenhla, abathengi kufanele bacabangele izidingo zabo kanye nezidingo zabo ezithile. Kufanele futhi babheke uhlobo lwenhlama abazoyilungisa, imvamisa, kanye nevolumu yokukhiqiza. Ukutshala imali enhlama yekhwalithi ephezulu namashidi aklanywe kahle kungakhokha kakhulu ngokusebenza kahle, ukusebenza, nokuphila isikhathi eside. Ukwengeza, ukuze uthole amashidi enhlama asebenza kahle kakhulu, vakashela Cooig.com.