Okuqukethwe

Iyini irutha ye-CNC?

Yiziphi izinto ezingasikwa ngemishini ye-CNC router?

Yiziphi izinhlelo zokusebenza ezifanele imishini ye-CNC router?

Usebenza kanjani umshini womzila we-CNC?

Ibiza malini irutha ye-CNC?

Ungalikhetha kanjani ithebula le-router ye-CNC

Yiziphi izinhlobo ezahlukene zemishini yomzila we-CNC?

Iyiphi isofthiwe engasetshenziselwa imishini yomzila we-CNC?

Yiziphi izilawuli ezingasetshenziselwa imishini ye-CNC router?

Yini okufanele uyazi ngaphambi kokuthenga umshini womzila we-CNC?

Ungawu-oda kanjani umshini womzila we-CNC

Imibuzo Evame Ukubuzwa

Iyini irutha ye-CNC?

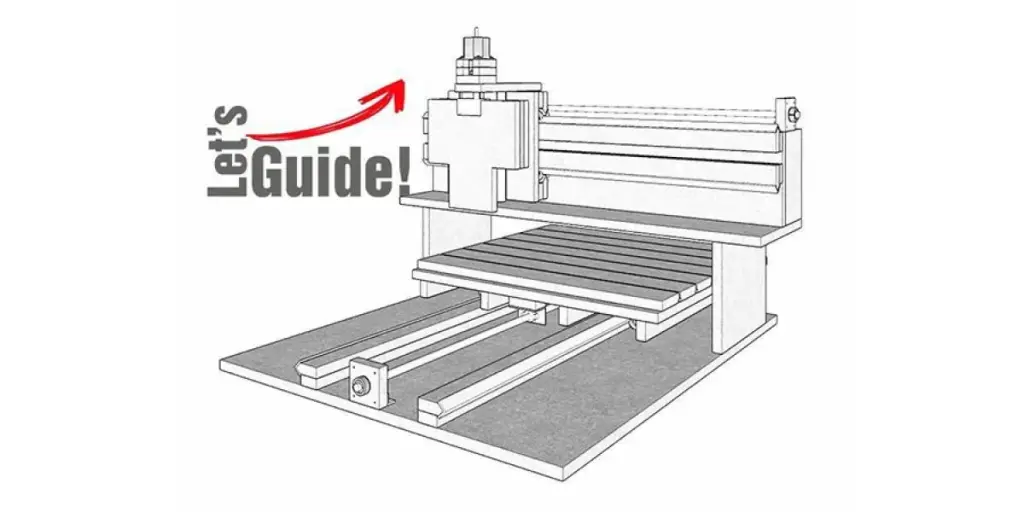

Irutha ye-CNC iwuhlobo lwethuluzi lomshini ozenzakalelayo elisetshenziswa nesistimu ye-CNC yokuqopha okuzenzakalelayo, ukuqopha, ukusika, ukugaya, ukubhoboza, nokugxusha kwezinto ezahlukene. Izinto ezinjengokhuni, igwebu, itshe, amapulasitiki, i-acrylic, ingilazi, i-ACM, ithusi, ithusi, i-aluminium, i-PVC, ne-MDF ingasetshenzwa. Le mishini ingakhiqiza izimo ezinembile neziyinkimbinkimbi namakhonsathi ngokwenza izinto ngomshini usebenzisa ithuluzi. Umshini werutha we-CNC ufinyelela le miphumela usebenzisa ubuncane bezimbazo ezintathu, u-X, Y, no-Z. I-eksisi ye-X ivundlile, isuka kwesokunxele iye kwesokudla, i-Y-eksisi ihlehle futhi iye phambili, futhi i-axis ye-Z ime mpo, okungukuthi phezulu naphansi. Lokhu, okubonwa ngokomfanekiso, kubangela lokho okubizwa ngokuthi ingosi, yingakho amarutha e-CNC anesakhiwo sephothali (i-X-axis eklanywe njengebhuloho) ngokuvamile ebizwa ngokuthi imishini yokugaya ingosi. Ngaphezu kwalokho, eminye imishini yokugaya inama-axes angu-A-, B-, kanye no-C amele ukuzungezisa izimbazo eziyinhloko u-X, Y, no-Z.

Yiziphi izinto ezingasikwa ngemishini ye-CNC router?

Imishini ye-CNC router ingasika izinto eziningi ezahlukahlukene, kufaka phakathi:

Wood

Foam

MDF

Plastics

Ama-acrylic

Stone

Copper

Brass

Aluminum

Glass

I-ACM

PVC

Yiziphi izinhlelo zokusebenza ezifanele imishini ye-CNC router?

Nawa amanye amathuba wohlelo lokusebenza oluhlukahlukene lwemishini ye-CNC router:

- Ukudweba kwe-2D

- Ukudweba kwe-3D

- I-Woodworking

- Ukwenziwa kwe-aluminium

- Ukwenziwa kwe-Acrylic

- Imibukiso nemidlalo

- I-Architectural millwork

- Ukwenza iKhabhinethi

- Ukwenza izimpawu

- Ukwenza iminyango

- Ukukhiqizwa kwefenisha

- Ukwenza isikhunta

- Imihlobiso

- Izinsimbi zomculo

- I-Aerospace

Usebenza kanjani umshini womzila we-CNC?

Umshini werutha we-CNC ulawulwa ngekhompuyutha. Yonke idatha edingekayo, ngendlela yamakhodi e-G, ihlanganiswa ibe uhlelo lwe-CNC. Amakhodi e-G ahlanganisa noma yiliphi igama kuhlelo lwe-CNC oluqala ngohlamvu G. Itshela ithuluzi lomshini ukuthi yiluphi uhlobo lwesenzo okufanele lenze, njengokunyakaza okusheshayo noma imigqa elawulwayo noma ama-arcs. Njengoba la makhodi emisiwe, angasuselwa ku-software yerutha ye-CNC esetshenziswa cishe kuyo yonke imishini yerutha ye-CNC. Lapho yonke idatha isifakiwe futhi nohlelo lwe-CNC selulungele ukuhamba, umshini we-CNC uqala ukusebenza. Abakhiqizi bangeze amakhodi abo kumakhodi e-ISO G, ngakho-ke, ama-post-processor amaningana akhona ukuze akhiqize izinhlelo "ezihambisanayo" ezivela ezinhlelweni ze-CAM zemishini ehlukene.

Ngokuzungezisa ithuluzi elifanele, noma ukusebenzisa i-spindle eguquliwe ebhekene nendawo yokusebenza eboshiwe, ukunyakaza kokusika okudingekayo komsebenzi owufunayo kukhiqizwa. Lokhu kunqunywa kusengaphambili ngokusekelwe kumakhodi e-G. Ithuluzi le-CNC lizungeza ucezu lokusebenza, lenze umumo onqunywe kusengaphambili. Lokhu kungafezwa, kuye ngomklamo werutha, ngokugudluzwa kwe-workpiece etafuleni eligudlukayo lerutha ye-CNC. Ngokusebenzisa zonke izimbazo ezitholakalayo, cishe wonke ama-geometri omsebenzi ayenzeka. Amafomu alandelayo angakhiwa:

Amamodeli e-3D afanele ukwakhiwa kwezakhiwo nokwakhiwa kwamamodeli

Izindawo ezikhululekile ze-3D

Ama-workpieces e-Roto-symmetrical

Ukubhala amagama kukho kokubili i-2D ne-3D

Ukuqoshwa ku-2D naku-3D

imicu

IGrooves

Ibiza malini irutha ye-CNC?

Izindleko zerutha ye-CNC kuncike kakhulu ekucushweni kwayo. Nakuba ungase ucabange ukuthi wonke amarutha e-CNC abukeka afana, kunomehluko omkhulu phakathi kwalokho angakwenza. Yonke imishini yenza imisebenzi eyisisekelo njengokusika, ukubhoboza, ukubhala amagama, ukuqopha indiza, ukusiza, njalonjalo, kodwa ukunemba, ukuxaka, isivinini, ukusebenza, kanye nentengo kuhluka kakhulu.

- Ibanga lentengo yerutha encane ye-CNC: $2,500 - $5,000

- Ibanga lentengo yerutha ye-CNC ejwayelekile: $3,000 – $10,000

- Ibanga lentengo yerutha ye-ATC CNC: $16,800 – $25,800

- Ibanga lentengo yerutha ye-5-Axis CNC: $95,000 – $180,000

- Ibanga lentengo yerutha ye-Smart CNC: $8,000- $60,000.

Ingabe zikhona izindleko ezengeziwe kanye nezindleko uma uthenga irutha ye-CNC?

Ngokungeziwe emshinini ngokwawo, uzodinga ukuthenga iphakheji yesofthiwe ye-computer-aid design (CAD) ukuze udale imiklamo yakho. Lezi zivame ukugijima kusuka ku-$2,000 kuya ku-$15,000.

Ukuqeqesha ngokuvamile kubiza noma yikuphi kusuka ku-$200 kuya ku-$500 ngosuku. Kuye ngezinga lolwazi lwamanje lwabasebenzi bakho, inqubo ingathatha amahora ambalwa noma izinsuku ezimbalwa. Ukufaka futhi kuvame ukubiza phakathi kuka-$200 kuya ku-$500 ngosuku.

Ukuthumela kuqala kumakhulu amaningana amadola futhi kungabiza kufika ku-$2,000, kuye ngendawo okuyiyonayona.

Abanye abathengisi banikeza amadili enqwaba afaka izindleko zomshini, ukuqeqeshwa, ukuthunyelwa, kanye nokufakwa. Qiniseka ukuthi uhlola ukuthi yiziphi amadili abazenzayo ngaphambi kokunquma ngokuthenga kwakho noma umdayisi.

Ungalikhetha kanjani ithebula le-router ye-CNC

Izinhlobo zethebula

Izinhlobo ezivame kakhulu zamathebula erutha ye-CNC zifaka iphrofayili, i-vacuum, namatafula e-adsorption block. Ithebula lephrofayela yerutha ye-CNC yaziwa nangokuthi itafula lokulungisa. Lolu hlobo lwetafula lucindezela ngokuqondile ucezu lokusebenza ngesikulufu sepuleti elicindezelayo, futhi lifanele ukusika, ukugoba, nezinye izinqubo, njengoba inqobo nje uma umoya ungaphuma, i-vacuum adsorption ayikwazi ukumuncwa. Lapho uthenga itafula lephrofayela, amakhasimende angaphinde akhethe imodeli ewafanele kangcono, ngokusekelwe ezicini ezimbili ezingenhla. Kodwa-ke, uma usebenzisa ithuluzi lokusika elinobubanzi obuncane (ngaphansi kuka-4mm), ngoba igebe lincane, amanye angabuye afakwe i-vacuum-adsorbed etafuleni.

Ithebula le-vacuum ye-CNC router linebhodi lokuminyana futhi lenziwe nge-wood fiber kanye neglue ngaphansi kwengcindezi ephezulu. Kunamapayipi noma izikhala phakathi kwezendlalelo ze-fiber yokhuni futhi ngemva kokuxhuma itheyiphu yokuvala, ipompo ye-vacuum ingavulwa ukuze kwakhiwe i-vacuum futhi ibambe ucezu lokusebenza ngokuphephile etafuleni. Lokhu kusindisa isikhathi faffing mayelana vices noma ngezikulufo futhi kufanelekile ikakhulukazi ukukhiqizwa mass of iminyango ngokhuni. Ngezinye izikhathi kungase kudingeke ukuthi kufakwe ibhodi elincane le-MDF kuqala. Ibhodi le-MDF libekwe etafuleni le-CNC router vacuum suction ukuvimbela isisiki sokugaya ukuthi singalimazi ithebula lokusebenza. Ukucindezela engxenyeni eseduze nebhodi lokuminyana kuphansi kakhulu kunokucindezela komkhathi ngakolunye uhlangothi, kwenza ingcindezi engalungile, ngakho-ke i-workpiece ibanjwe ngokuqinile ngokumangalisayo futhi ayinazo izikulufo ezicasulayo noma izinsimbi endleleni. Isibonelo, kuyisimiso esifanayo nalapho amashidi amabili engilazi enamathele ndawonye futhi kunzima ukuwahlukanisa. Uma uphawu lungasaqinile, akukho ukucindezela okungalungile, ngakho-ke ingcindezi ezinhlangothini zombili zepuleti le-workpiece iyafana, futhi kuba lula ukuhlukana.

Osayizi Bethebula

Amasayizi wethebula le-CNC ajwayelekile kakhulu ahlanganisa: 2′ x 2′, 2′ x 3′, 2′ x 4′, 4′ x 6′, 4′ x 8′, 5′ x 10′, kanye 6′ x 12′.

Iyiphi i-spindle yerutha ye-CNC okufanele uyikhethe?

I-spindle ingenye yezingxenye ezibaluleke kakhulu zomshini we-CNC router. Umshini ngokuvamile udinga ukuhlonyiswa nge-spindle esebenza kahle kakhulu ukuze ufeze imisebenzi yawo. Izinga le-spindle lithinta ngqo isivinini sokucubungula nokunemba komshini we-CNC router, ngakho ukukhetha i-spindle efanele kubaluleke kakhulu. Ngakho, nakhu okudingeka ukuhlole:

1. Yahlulela ukuthi i-spindle iyikhwalithi ephezulu, noma ibukeka ishibhile.

1.1. Ingabe i-spindle motor isebenzisa ama-bearings anembe kakhulu? Uma ama-bearings anembe kakhulu engasetshenziswa, injini yokuphotha izoshisa kakhulu ngemva kokujikeleza kwesivinini esikhulu, okuzothinta impilo yesevisi ye-spindle motor.

1.2. Ingabe iyunifomu yomsindo futhi iyavumelana lapho uzungeza ngesivinini esihlukile, ikakhulukazi ngesivinini esikhulu?

1.3. Ingabe i-spindle ingaphansi kwamandla ekuqondeni kwe-radial? Iphuzu eliyinhloko lokubhekisela kulo ukuthi kungenzeka yini ukusika izinto eziqinile ngesivinini esikhulu. Amanye ama-spindle angasika kuphela izinto eziqinile ngesivinini esiphansi kakhulu, ngaphandle kwalokho, ukusebenza kwe-spindle kuzoba kubi, okuzothinta ukunemba kokuphotha ngemuva kwesikhathi esithile, noma kubangele nokungasebenzi kahle.

1.4. Uma ufuna ukusebenza kahle kokucubungula okuphezulu, isivinini sokucubungula kufanele sisheshe, ngokusikwa kommese omkhulu. Lapho ulungisa izinto zokhuni oluqinile, uzodinga injini yokuphotha enamandla angu-2.2KW noma ngaphezulu.

1.5. Ukucushwa okujwayelekile komshini we-CNC kuyehluka ngokuya ngemininingwane yemishini.

2. Ukukhetha i-spindle yerutha ye-CNC efanele ngokwezinhlelo zokusebenza ezahlukene.

2.1. Into eqoshwe umshini womzila we-CNC okhangisiwe iyimpahla ethambile, ngakho amandla okuphotha adinga kuphela u-1.5kw - 3.0kw. Uma ukhetha lolu hlobo, ungafinyelela umzila ngenkathi ulondoloza ezindlekweni.

2.2. Amandla we-CNC wood router spindle motors angakhethwa ngokuya ngobulukhuni bokhuni okumele lucutshungulwe. Kodwa-ke, ngokuvamile ebalelwa ku-2.2kw – 4.5kw, kufanele yenze umsebenzi.

2.3. Amandla okuphotha emishini ye-CNC yamatshe aphakeme kakhulu, acishe abe ngu-4.5kw – 7.5kw, kanti i-spindle motor engu-5.5kw iyona esetshenziswa kakhulu.

2.4. Amandla okuphotha we-Foam CNC router kufanele futhi akhethwe ngokuvumelana nokuqina kwegwebu okufanele kusetshenzwe. Ngokujwayelekile, u-1.5kw – 2.2kw uzohlangabezana nezidingo zamakhasimende.

2.5. Ngenxa yobulukhuni obukhulu bemishini ye-CNC router yensimbi, amandla e-spindle motor ngokuvamile aphakathi kuka-5.5kw - 9kw.

Ngamanye amazwi, i-spindle motor enamandla kakhulu imosha amandla kagesi futhi inyuse intengo yokuthenga yasekuqaleni. Uma amandla ephansi kakhulu isidingo samandla omzila ngeke sitholakale. Ngakho-ke, ukukhetha amandla e-spindle motor afanelekile kubalulekile.

3. Ubudlelwano phakathi komshini we-CNC router kanye nezinto zomzila.

Uma bukhulu ubulukhuni bempahla yomzila, ijubane lokujikeleza liyancipha. Lokhu kuwumqondo nje. Izinto eziqinile zidinga ukugaywa kancane futhi uma isivinini sokuzungezisa sishesha kakhulu, ithuluzi lingase lonakale. Ukuphakama kwe-viscosity yezinto zomzila, kuyanda ukuphotha okusetshenzisiwe. Lokhu ikakhulukazi okwezinsimbi ezithambile noma izinto ezenziwe umuntu.

Ububanzi bethuluzi elisetshenziswa emishinini yomzila we-CNC nakho kuyisici esibalulekile ekunqumeni isivinini sokuphotha. Ububanzi bethuluzi elisebenzayo buhlobene nezinto zokucubungula kanye nomugqa wokucubungula. Uma ubukhulu bethuluzi bukhulu, ijubane lokuphotha lizohamba kancane. Ukunquma isivinini sokuphotha kufanele kusekelwe ekusetshenzisweni kwe-spindle motor. Lapho isivinini sokuphotha sincipha, amandla okukhipha imoto nawo ayancipha. Uma amandla okukhiphayo ehla aze afike ezingeni elithile, azothinta ukucubungula, okuzothinta kabi impilo yamathuluzi kanye nomsebenzi. Ngakho-ke, lapho unquma isivinini sokuphotha, qiniseka ukuthi i-spindle motor inamandla okukhipha afanele.

Yiziphi izinhlobo ezahlukene zemishini yomzila we-CNC?

Ake sibheke izinhlobo eziyi-10 ezivame kakhulu zemishini ye-CNC router, ngokuya ngemisebenzi ehlukene, izimbazo, izinto zokwakha, kanye nezinhlelo zokusebenza.

Thayipha 1: Amarutha amancane e-CNC amabhizinisi amancane

Thayipha 2: Amarutha we-CNC wokuzilibazisa wama-hobbyists

Thayipha 3: Amarutha edeskithophu e-CNC ezitolo zasekhaya

Thayipha 4: Amarutha e-Industrial CNC okusebenza ngokhuni

Uhlobo 5: Amarutha e-ATC CNC anokushintsha ithuluzi okuzenzakalelayo

Uhlobo 6: Imishini yokufaka izidleke ye-CNC yokwenza ikhabethe

Thayipha 7: 4-Axis CNC amarutha anetafula elijikelezayo

Thayipha 8: amarutha e-5-Axis CNC omodeli we-3D

Uhlobo 9: Amarutha e-Metal CNC e-aluminium

Thayipha i-10: Amarutha e-Foam CNC e-EPS ne-Styrofoam

Iyiphi isofthiwe engasetshenziselwa imishini yomzila we-CNC?

I-Type3

I-Type3 iyisisombululo sesoftware ye-CNC eyindilinga yonke yezidingo zedizayini yezithombe zokhuni. Isebenza ngaphansi kwesistimu ye-Microsoft Windows, inephakheji yesofthiwe ye-graphic design engcono kakhulu, futhi ihlanganiswe eduze nenqubo yokucubungula. Ukusuka ezinhlamvu ezilula kuye ekwenzeni iphethini eyinkimbinkimbi, i-Type3 inemisebenzi enamandla kanye nokuguquguquka kokuxazulula zonke izinkinga eziqoshiwe ezichwepheshile. I-Type3 ifanela zonke izidingo zakho futhi kulula ukuyifunda nokusebenzisa. Kuyi-software eyindilinga yokudala kanye nokucubungula okuqoshiwe. I-Type3 ingabala ngokunembile indlela yamathuluzi enezinhlangothi ezintathu, ithuthukise indlela yokucubungula umshini, ikhiqize umzila we-CNC, futhi ekugcineni ikhiqize ikhodi yomzila ye-CNC. Ungakhetha ngokukhululekile amathuluzi ahlukahlukene kanye nokubhoboza okuhlanganisa ikhoni, eyindilinga, nezinhlobo eziyisilinda zomzila.

Ucancam

I-Ucancam isofthiwe ekhethekile ehlanganisa i-computer-aid design (CAD) kanye nokukhiqiza okusizwayo (CAM). Isetshenziswa kakhulu ezinhlelweni eziningi ezifana nokukhangisa, izimpawu, izipho, umhlobiso, ubuciko, ukucubungula izinkuni, kanye nezibungu, ukubala ezimbalwa nje.

Isoftware yochungechunge lwe-Ucancam inomklamo wehluzo onamandla nemisebenzi yokuhlela, isekela okokufaka kokudidiyela futhi ingadweba ngokunembile ihluzo. Iphinde inikeze imisebenzi efana nokukopisha inqwaba, ukuguqulwa kobuciko, ukunqampuna okuguquguqukayo, nokuhlelwa kwamanodi ukuze kube lula ukuhlelwa kwezithombe nokuguqulwa. Ukuzalela okuzenzakalelayo nokusebenzisanayo kukhulisa izinga lokusetshenziswa kwezinto zokwakha kanye nezinhlobo zohlobo ngokushesha.

Ngokubala kwendlela yamathuluzi ezinhlangothi ezintathu esheshayo nenembile, uhlelo lwe-Ucancam post-machining lulungele ukusetha izidingo zekhodi zemishini ehlukene. Yehlisa ukulimala kwethuluzi noma impahla futhi ayishiyi izimpawu zommese endaweni yokusika. I-Cycloid machining inikeza ukwesekwa okuqinile kobuchwepheshe bokusika amatshe aqinile, ingilazi, nezinto eziphukayo. Ngesikhathi esifanayo, izinhlobonhlobo zezindlela zokwenza imishini ezihlanganisa i-3D, i-central linening, ukubhoboza, ukufaka inlaying, unqenqema nokufaka amakhona, ukudweba okuyindilinga, ukuqoshwa kwesithombe, nokusizwa kwesithombe kuyatholakala, kuye ngezidingo zamakhasimende. Ngaphezu kwalokho, ukucubungula ukulingisa, imisebenzi yokulingisa, kanye nesibonisi semiphumela yomshini elula nesheshayo kunciphisa inqubo yesilingo somshini futhi ngakho-ke kunciphisa izindleko zomshini.

I-ArtCAM

Uchungechunge lomkhiqizo wesoftware ye-ArtCAM, ekhiqizwe yinkampani yase-UK iDelcam, ihlinzeka ngemodeli eyingqayizivele ye-CAD, kanye nesisombululo sokucubungula se-CNC ne-CAM. Kuyisixazululo esithandwayo sesoftware ye-CAD/CAM yedizayini yokusiza enezinhlangothi ezintathu, idizayini yobucwebe, nokucutshungulwa. Ingakwazi ukuguqula ngokushesha imibono ye-2D ibe imikhiqizo yobuciko ye-3D. I-interface ye-All-Chinese yenza abasebenzisi baklame futhi bacubungule ukukhululeka kwe-3D kalula, ngokushesha, nangokuvumelana nezimo. Isetshenziswa kabanzi emkhakheni wokukhiqiza ukuqoshwa, ukukhiqizwa kwesikhunta, ukukhiqizwa kobucwebe, ukuklama ukupakisha, ukukhiqiza indondo nezinhlamvu zemali, nokwenza izimpawu.

Uchungechunge lwesofthiwe ye-Delcam ArtCAM lungaguqula idatha yendiza efana nokusalungiswa okudwetshwe ngesandla, amafayela askeniwe, izithombe, amamephu ampunga, i-CAD, namanye amafayela, abe amamodeli edijithali e-3D acacile futhi amahle, kanye nokukhiqiza amakhodi angashayela ukusebenza kwethuluzi lomshini we-CNC. I-ArtCAM ifaka ingcebo yamamojula asebenza ngokugcwele, asebenza ngokushesha, athembekile, futhi anobuhlakani obudlulele. Ngokusebenzisa amamodeli osizo akhiqizwe yi-Delcam ArtCAM, imodeli yokusiza eyinkimbinkimbi kakhulu ingakhiqizwa ngemisebenzi ye-Boolean efana nenyunyana, ukuhlangana, umehluko, inhlanganisela engafanele, i-superposition, kanye nokuhlanganisa. Futhi, unganikeza futhi ucubungule ukukhululeka okuklanyiwe. Abasebenzisi abadingi ukuchitha isikhathi nemali ukuze bakhe amamodeli wangempela ngoba bangakwazi ukubona imiphumela yedizayini yangempela khona lapho esikrinini.

I-Alphacam

I-Alphacam yakhiwe nguLycome waseCoventry, e-UK, futhi iyiphakheji yesoftware ye-CAM enamandla. Isofthiwe yerutha ye-CNC ine-contour milling enamandla kanye nenani elingenamkhawulo lamathuluzi okwenza ephaketheni angahlanza ngokuzenzakalelayo izinto ezisele futhi enze izilungiselelo ngendlela oyifisayo. Indlela yamathuluzi nesivinini kuvela kuwo wonke amawindi ngesikhathi esisodwa ukuze kufanekiswe okubonakalayo okuguquguqukayo.

Isoftware ye-Alphacam yokuzenzela isidleke njengamanje iyisoftware ejwayelekile esetshenziswa embonini yokucubungula umnyango wekhabethe. Inzuzo yayo enkulu ukuthi uhlobo lomnyango ludinga kuphela ukusungula imodeli yokucubungula (indlela yamathuluzi) kanye, futhi ingakwazi ukubona isidleke esizenzakalelayo sanoma yimuphi usayizi ngaphandle kwesidingo sokuphinda udwebe. Ngenxa yalokho, ukusebenza kahle kuthuthukiswa kakhulu uma kuqhathaniswa nesofthiwe evamile.

Umbono weKhabhinethi (CV)

I-Cabinet Vision iyisofthiwe ye-3D edidiyelwe yokuklama ngokwezifiso ehambisana neWindows. Ingabona kalula idizayini eyisizayo enembile kanye nemidwebo yobungcweti ngokuhambisana ngokuqinile nezicaciso zedizayini yebhizinisi. Kunikezelwe kumakhabethe namawodilophu, kulula ukusebenza futhi kunamandla, Umbono Wekhabhinethi ungasiza ngokunembile ekumisweni kwezindonga, ukhethe futhi uklame ihluzo zomkhiqizo wesistimu yenkampani, futhi ukhiqize ngokuhambisanayo amapulani aphansi, ukuphakama, ukubukwa okuseceleni, ukuhumusha kwezinhlangothi ezintathu, kanye nokubukwa okuqhume. Ingakwazi futhi ukukhiqiza ngokuzenzakalela ukubukwa okuningi kokunikezela futhi ifane ngokugcwele nezidingo ezibukwayo zekhasimende. Ngaphezu kwalokho, ukukhiqizwa okuzenzakalelayo kwezingcaphuno zokuthengisa kanye nohlu lwezingxenye, ukuhlukaniswa okuzenzakalelayo, nokuklama nokuhlukanisa, kuthatha imizuzu engu-30 kuphela, namaphutha angu-zero nokuhambisana ngokuqinile nezindinganiso zomkhakha.

Ikhabethe elinembile eliphelele kanye nomklamo wesitolo ungakhiqizwa ngesikhathi sangempela esitolo, ngokuya ngezidingo ezenziwe ngokwezifiso zekhasimende, ukunikezwa okuhlukahlukene, nohlu lwezitolo. Lokhu bese kuxhuma nesiphetho sangemva kokucubungula sefekthri, ukubeka ama-oda ukude ngenkathi uqondisa inqubo yokukhiqiza.

Yiziphi izilawuli ezingasetshenziselwa imishini ye-CNC router?

I-Mach3 CNC Controller

Uma isebenza kukhompyutha, i-Mach3 iyisistimu yokulawula ithuluzi lomshini ukonga futhi elinamandla. Yisilawuli se-CNC esidume kakhulu emhlabeni wonke. Ukusebenza kwe-Mach3 kudinga ikhompuyutha okungenani enephrosesa engu-1GHz nesibonisi samaphikseli angu-1024—768. Uhlelo lweWindows lungasebenza ngokugcwele kulokhu kumisa. Amakhompiyutha edeskithophu asebenza kakhulu futhi ayonga kunamakhompuyutha ezincwadi. Uma ikhompuyutha ingasetshenziselwa ukulawula ithuluzi lomshini, ingasetshenziselwa eminye imisebenzi yeshabhu. I-Mach3 idlulisa kakhulu amasiginali ngembobo ehambisanayo, kodwa futhi ingadlulisela ngembobo yomkhiqizo. Izinjini zokushayela zethuluzi ngalinye lomshini kufanele zikwazi ukwamukela zombili izimpawu zesinyathelo nezimpawu eziqondile. Wonke ama-stepper motors, ama-DC servo motors, kanye nama-AC servo motors anamakhodi edijithali ayahlangabezana nale mfuneko. Kuhle ukuqaphela ukuthi uma ufuna ukulawula ithuluzi lomshini we-CNC elidala ngesistimu ye-servo esebenzisa isixazululi ukukala indawo yethuluzi, kuzodingeka ukuthi esikhundleni se-eksisi ngayinye ufake injini entsha yokushayela.

Isilawuli se-CNC studio

Isilawuli se-CNC studio sivela eChina. Uhlelo lwe-CNC lungasekela ngokuqondile amafomethi ekhodi ye-G kanye nekhodi ye-PLT kanye nomzila omuhle owenziwe yi-MASTERCAM, UG, ArtCAM, CASMATE, AUTOCAD, CorelDraw, nenye isofthiwe ye-CAM/CAD. Ngokungeziwe emisebenzini yokubuyisela eyenziwa ngesandla, yokunyathela, ezenzakalelayo, neyomsuka womshini, isitudiyo se-NC siphinde sibe nemisebenzi ehlukile efana nokulingisa, ukulandelela isibonisi esiguqukayo, ukulungiselelwa kwamathuluzi okuzenzakalelayo kwe-Z-axis, inkumbulo ye-breakpoint (ukuqaliswa kokweqa uhlelo), nokucutshungulwa kwe-axis ejikelezayo. Lolu hlelo lungasetshenziswa namarutha amaningana e-3D CNC kanye nezigayo ze-3D CNC. Ilungele zonke izinhlobo zokucubungula isikhunta esiyinkimbinkimbi, izinto zokukhangisa, ukusika, nezinye izimboni.

Isilawuli se-Syntec CNC

I-Syntec iwuhlelo lokulawula lwe-CNC oludumile olwakhiwe yi-Taiwan Syntec Technology Co. Ltd. I-Taiwan Syntec okwamanje iwumkhiqizo othembisayo kakhulu we-CNC osekelwe ku-PC osebenza ngokukhethekile ku-R&D, ukukhiqiza, ukuthengisa, kanye nesevisi yezilawuli ze-CNC ezisekelwe ku-PC. Umshini womzila we-CNC wesistimu we-Syntec unikeza ukusebenza okuzinzile, ukusebenza okulula nokuvumelana nezimo, ukusekelwa kwezinhlelo ezimbili, izibonisi zezinhlelo ezintathu nezine, kanye nezixhumanisi zemishini. Ukuhlela uhlelo nokuqapha kwenqubo kwenziwa ngokwehlukana, izixhumanisi zeqembu ngalinye le-eksisi ziboniswa ngokuzimela, futhi iqembu le-eksisi ngalinye lingenziwa ngesikhathi esifanayo ukuze lizungezise izixhumanisi zohlelo. Kulula ukubhala uhlelo lokucubungula, ukwenza ukucubungula okunezinhlangothi ezintathu endaweni ethambekele, nokusebenzisa ukugaya, ukubhola, nokuthepha.

Uhlelo lusekela imodi yokulawula ukuxhumana kwebhasi yase-Yaskawa, enciphisa kakhulu izindleko zezintambo kanye nezidingo zesikhala, futhi ithuthukise ukusebenza kahle kwezindleko. Indlela yokulawula ukuxhumana kwebhasi yase-Yaskawa isiza ukuthuthukisa izinkinga zezintambo nokunwebeka kwezilawuli zenhloso evamile yohlobo lwe-pulse ukuze uhlelo lube lula, lunwebeke, futhi lube lula ukuhlangana.

Isilawuli se-DSP

Isilawuli se-DSP siyisistimu yokulawula isibambo engasebenza ungaxhunyiwe ku-inthanethi. Ingahlukaniswa nekhompyutha phakathi nenqubo yokuqopha futhi ingalawula ngokuqondile umshini wokuqopha. Izuza ekusebenzeni kwesibambo, idizayini eyenziwe umuntu, isibonisi esikhulu sesikrini, isixhumi esibonakalayo sezilimi eziningi, ukusebenza okulula, nokulungiswa okulula. I-algorithm ehlukile yokuqagela ehlakaniphile iyamukelwa ukuze inikeze ukudlala okugcwele emandleni enjini, ibone ukucubungula okuqhubekayo kwesivinini esikhulu, ukuvumelanisa amajika nemigqa eqondile, nokwenza amajika ashelele.

Uhlelo lunokulungiswa kwamaphutha e-Super, okungahlola kusengaphambili amadokhumenti okucubungula, ukuvimbela amaphutha okubhala noma okuklama ekucubunguleni amadokhumenti, futhi kuvimbele ukubekwa kwezinto ngaphandle kwebanga lokucubungula.

NK CNC Isilawuli

Uhlelo lokulawula uchungechunge lwe-NK luwumshini wokonga konke-kokukodwa onokwethenjelwa okuphezulu nokusebenza kwezindleko eziphezulu. Ingenise ama-micro switch, okhiye bomsebenzi wephaneli bangalungiswa, futhi izimbobo zesikhathi zingenziwa ngokwezifiso, zinikeze ukungenisa nokuthekelisa kwepharamitha, kanye nemisebenzi yesipele yesistimu elula nesheshayo. Ibhodi letheminali elingemuva komshini ohlanganisa yonke into lihlinzeka ngembobo yokufaka amandla angu-24V, imbobo ye-USB, imbobo yesondo lesandla, imbobo yokufaka amabhuleki, imbobo yokukhipha amabhuleki, imbobo yokuphuma kwe-analog, isixhumi esibonakalayo se-servo drive (i-X-eksisi, i-Y-eksisi, i-Z-eksisi) edingwa uhlelo. Iphinde ibe namachweba wokufaka wenhloso ejwayelekile ayi-16 kanye nezindawo eziyi-8 zokuphuma kwezinhloso ezijwayelekile. Iphaneli yokusebenza inenkinobho yokumisa isimo esiphuthumayo, inkinobho yamandla, ukubhala ngaphezulu kokuphotha, namaswishi ebhendi yokubhala ngaphezulu kwesilinganiso sokuphakelayo.

Yini okufanele uyazi ngaphambi kokuthenga umshini womzila we-CNC?

Ngaphambi kokutshala imali emshinini we-CNC router, noma yimuphi umshini we-CNC wokhuni, kuwumqondo omuhle ukuvakashela umsebenzisi okhona futhi uthole i-akhawunti mathupha yomshini kumuntu oke wayisebenzisa ngempela. Zama ukuzivakashela ngokwakho, ngaphandle komthengisi eduze, ukuze uthole ukuzwa ngempela ukuthi kubasebenzele kanjani.

Uma ungasitholi isitolo esisebenzisa umshini we-CNC ofuna ukusibuka, ungabuka umbukiso ongaphakathi mathupha noma uxhumeke ku-inthanethi. Lena indlela engcono kakhulu yokuqonda ukuthi umshini we-CNC usebenza kanjani, futhi ungawubona uqedela umsebenzi kusukela ekuqaleni kuze kube sekupheleni.

Ungawu-oda kanjani umshini womzila we-CNC

1. Ukubonisana: sizokuncoma amakhithi erutha e-CNC afaneleka kakhulu kuwe ngemva kokuhlola izidingo zakho, njengempahla ofuna ukuyiqopha kanye nobukhulu obukhulu bento (ubude x ububanzi x ukujiya).

2. Ikhotheshini: Sizokuthumelela ikhotheshini yamahhala yezinsiza zakho zerutha ye-CNC ngamanani akhokhelekayo.

3. Ukuhlolwa kwenqubo: Zombili izinhlangothi zihlola ngokucophelela futhi zixoxisane ngayo yonke imininingwane yomyalelo ukuvimbela noma yikuphi ukungaqondi.

4. Ukufaka i-oda: Uma konke kuvunyelwene, sizokuthumelela i-PI (I-invoyisi ye-Proforma), bese sisayina inkontileka nawe.

5. Ukukhiqiza: Sizohlela ukukhiqiza ngokushesha lapho sithola inkontileka yakho yokuthengisa esayiniwe kanye nediphozithi. Uzogcinwa unolwazi lwakamuva kuzo zonke izigaba zenqubo.

6. Ukuhlola: Inqubo yokukhiqiza izoba ngaphansi kokuhlolwa okuvamile nokulawulwa kwekhwalithi okuqinile. Umshini oqediwe werutha we-CNC uzohlolwa ukuze kuqinisekiswe ukuthi usebenza kahle ngaphambi kokuthi uphume efekthri.

7. Ukulethwa: Sizohlela ukulethwa ngokwemibandela yenkontileka ngemuva kokuqinisekisa okuvela kumthengi.

8. Ukuvunyelwa kweCustoms: Sizohlinzeka futhi silethe wonke amadokhumenti okuthumela adingekayo kumthengi futhi siqinisekise imvume yenkambiso ebushelelezi.

9. Ukwesekwa kanye nensizakalo yangemva kokuthengisa: Sinikezela ngosekelo lobuchwepheshe ubusuku nemini kanye nesevisi yerutha ye-CNC ngocingo, i-imeyili, i-Skype, noma i-WhatsApp.

Imibuzo Evame Ukubuzwa

Ungawusetha kanjani, uwufake, futhi uwulungise kanjani umshini werutha we-CNC

Isinyathelo 1. Ukusetha uhlaka lomshini.

1.1. Vula ibhokisi lokupakisha futhi uhlole ukuthi umshini ubonakala uphelele.

1.2. Bala izingxenye zomzimba ngokohlu lokupakisha.

1.3. Beka kancane umshini werutha we-CNC esisekelweni esinamamitha awo amane phansi.

1.4. Lungisa izinyawo ukuqinisekisa ukuthi indawo yokusebenza yomshini isezingeni.

1.5. Khipha ingxenye yekhava yangaphandle bese usebenzisa indwangu kasilika ehlanzekile kanye nophalafini (noma uphethiloli) ukuze uhlanze uwoyela ovimbela ukugqwala esikulukweni sokuhola kanye nesitimela sokuqondisa, ususe noma yimaphi amafutha okugcoba kanye nokungcola.

1.6. Engeza amafutha okugcoba ezingxenyeni zendlela yokunyakaza njengesikulufu sokuhola kanye nomzila wesitimela.

1.7. Misa ikhava yangaphandle ngenkathi uqaphela ukuthi ungangqubuzani nezingxenye ezihambayo.

1.8. Gcoba kahle uhlaka lomshini.

Isinyathelo 2. Faka izinsiza zerutha ye-CNC.

2.1. Faka ithange lamanzi okupholisa lenjini yokupholisa, xhuma ithange nepayipi lokupholisa lenjini yokupholisa bese wengeza amanzi okupholisa ethangini lamanzi, okufanele kube amanzi athambile.

2.2. Faka isistimu yokupholisa isiqeshana sokusebenza, xhuma ithange lokupholisa endaweni yokuphuma amanzi ye-diversion groove yombhede ngepayipi lamanzi, bese uxhuma ipayipi lamanzi eliphezulu. Engeza isipholisi se-workpiece eshiwo ebhokisini lokupholisa le-workpiece.

2.3. Faka ithuluzi lokusetha futhi uxhume futhi ukhiye umugqa wesignali wethuluzi lokusetha ngesixhumi esibonakalayo sethuluzi lokusetha ithuluzi.

Isinyathelo sesi-3. Setha ikhabethe lokulawula ugesi.

3.1. Gcoba kahle ikhabethe lokulawula ugesi.

3.2. Xhuma futhi ukhiye isixhumi esibonakalayo sokufakwayo kwethuluzi lomshini ngalinye nesixhumi esibonakalayo esihambisanayo sekhabethe lokulawula ugesi ngekhebula lokulawula.

3.3. Xhuma isixhumi esibonakalayo sokulawula okokufaka kwekhabhinethi kagesi kukhompuyutha yokulawula ngekhebula lokulawula, futhi ulivikele ngezikulufu.

3.4. Xhuma futhi ukhiye isixhumi esibonakalayo phakathi kwekhibhodi yokusebenza kanye nekhabhinethi yokulawula kagesi ngekhebula lokulawula.

3.5. Vala isishintshi samandla ekhabetheni lokulawula ugesi bese uxhuma isokhethi yamandla ku-220V, 50HZ amandla kagesi.

Isinyathelo 4. Faka isistimu yokulawula ye-CNC nesofthiwe.

4.1. Vula ikhompuyutha yokulawula.

4.2. Faka isistimu yokulawula umshini we-CNC enamathiselwe.

Isinyathelo sesi-5. Ukulungisa iphutha nokusebenza kwesilingo.

5.1. Ngemva kokuhlola ukuthi zonke izintambo zesignali zixhunywe ngendlela efanele, futhi isisekelo esidingekayo siyenelisa, vula inkinobho yamandla ekhabhinethi yokulawula kagesi bese uyifudumeza imizuzu eyi-10.

5.2. Sebenzisa ikhibhodi yokusebenza ukuze uhlole ukuthi ingabe isimo sethuluzi lomshini kanye nokunyakaza kujwayelekile.

5.3. Qalisa ukuhlolwa kwe-idling bese wengeza amafutha okugcoba kumshini wokunyakaza.

Ungawusebenzisa kanjani umshini womzila we-CNC

1. Setha ukwakheka kanye nokuhlelwa kwezinhlobo ngokwezidingo. Ngemva kokubala ngendlela efanele indlela, gcina indlela yethuluzi elakhiwe njengefayela elihlukile lerutha ye-CNC.

2. Ngemva kokuhlola ukuthi indlela ilungile, vula ifayela lendlela ohlelweni lokulawula lwe-CNC (ukubuka kuqala kuyatholakala).

3. Lungisa okokusebenza bese uchaza umsuka womsebenzi. Vula i-spindle motor bese ulungisa amapharamitha ngendlela efanele.

4. Vula amandla futhi usebenzise umshini.

Isibani sesikhombi samandla sizokhanyisa ngemva kokuvula iswishi yamandla. Umshini uzokwenza umsebenzi wokusetha kabusha nokuzihlola, izimbazo ze-X-, Y-, kanye no-Z zibuyela endaweni eyiziro, bese zigijima ziye endaweni yazo yokuqala yokulinda (umsuka wokuqala womshini). Sebenzisa isilawuli ukuze uqondanise i-X-, Y-, ne-Z-eksisi nendawo yokuqala (umsuka wokucubungula) womsebenzi womzila. Khetha isivinini sokuphenduka esidingekayo kanye nesivinini sokuphakelayo ukuze ubeke umshini we-CNC esimweni sokumisa okwesikhashana. Dlulisela ifayela elihleliwe emshinini werutha we-CNC ukuze uqedele ngokuzenzakalelayo umsebenzi wokuklama umzila.

Ungawugcina kanjani umshini womzila we-CNC

- Susa uthuli ebhokisini likagesi njalo (ngokokusetshenziswa), futhi uhlole ukuthi amatheminali ezintambo kanye nezikulufu zengxenye ziqinile yini ukuze uqinisekise ukusetshenziswa okuphephile nokuthembekile kwesekhethi.

- Ngemuva kokusetshenziswa ngakunye, qiniseka ukuthi uhlanza noma yiluphi uthuli nemfucumfucu endaweni yomshini kanye nesistimu yokudlulisela, ngaphandle kwalokho uthuli oluningi nokungcola kuzongena kusikulufu, umzila wesitimela, kanye ne-bearing. Ukumelana nokuzungezisa kwesikulufu sokuhola kanye ne-bearing kukhulu, okungaholela ekugxumeni nasekuhlukaniseni lapho isivinini sombhalo sishesha kancane. Qinisekisa ukuthi isistimu yokudlulisa (X-, Y-, Z-axis) igcotshiwe futhi igcotshwe njalo (okungenani masonto onke).

- Kunconywa ukuthi umshini we-CNC router ungaqhutshwa ngokuqhubekayo amahora angaphezu kwe-10 ngosuku.

- Iphampu yamanzi kanye ne-spindle kuhlobene. Amanzi ajikelezayo kufanele ashintshwe ukuze kugcinwe amanzi ehlanzekile futhi kuvimbele indawo yokuphuma kwamanzi yepompo ukuthi ivaleke. Lokhu kuzophinde kuvimbele ukuphotha okupholiswe ngamanzi ekushiseni ngokweqile futhi kubangele ukulimala kwengxenye futhi kuqinisekisa ukusebenza okuvamile kwepompo yamanzi. Ungalokothi uvumele ukuphotha okupholiswe ngamanzi ukuthi kusebenze ngaphandle kwamanzi anele.

- Uma umshini ungasetshenziswa isikhathi eside, kufanele usagcotshwa njalo (isonto ngalinye) futhi usebenze ungenalutho ukuze kuqinisekiswe ukuguquguquka kwesistimu yokudlulisela.

Isifinyezo

Ngemva kokuthola umshini wakho werutha ye-CNC uchwepheshe ngokuvamile uzokusiza ekukhipheni nasekuhloleni umshini. Ngemva kokuyivula, kufanele uhlole ngokucophelela ukuthi akukho yini okubonakala yonakele ngesikhathi sokuthutha. Uma konke kuhamba kahle, hlola zonke izinanyathiselwa zokucushwa komshini ngokuya ngenkontileka zikhona usebenzisa imanuwali. Ochwepheshe bazofaka umshini ohlanganisa ukufakwa kwezingxenyekazi zekhompuyutha, ukususwa kwanoma yiziphi izingxenye ezigxilile, kanye nokuxhunywa kokuphakelwa kukagesi. Isofthiwe, ukucushwa kwekhompyutha, nanoma iyiphi isofthiwe yerutha ye-CNC engakhethwa nayo izofakwa. Ukulandela lokho, ifayela lokudweba lokuhlola elinikezwe umenzi lizosetshenziswa ukuhlola umshini. Uma ukuhlolwa kuqediwe ngendlela efanele, ukulethwa nokwamukelwa komshini kuqediwe.

Ama-opharetha e-CNC kudingeka ukuthi abe neziqu zemfundo yesikole samabanga aphakeme noma ngaphezulu futhi abe nesisekelo sokusebenza kwekhompyutha esinekhono. Phakathi nenqubo yokuqeqeshwa, baba nekhono ekukhetheni isivinini esihlukene sezinto ezihlukene nokusebenzisa amathuluzi erutha ehlukene ye-CNC. Lokhu kuvame ukudinga isipiliyoni esibanzi futhi ubuchwepheshe babo busiza ukwandisa impilo yemishini yomzila we-CNC namathuluzi.

Umthombo ovela stylecnc.com

Umshwana wokuzihlangula: Ulwazi olubekwe ngenhla luhlinzekwa yi-stylecnc independentiy ye-Cooig.com. I-Cooig.com ayenzi izethulo namawaranti ngekhwalithi nokuthembeka komdayisi nemikhiqizo.