Uma usendaweni yokukhiqiza futhi usika ubuciko obuhle noma ukwenza izingxenye zensimbi, uzodinga umshini wokusika i-plasma ozokunikeza ukusikeka okusheshayo nokuhlanzekile. Mayelana nokwakhiwa kwensimbi, kukhona okuzenzakalelayo CNC plasma amatafula ezisebenzisa amakhompuyutha ukuze zizenzele ukusikwa okunembayo ekukhiqizeni izimboni futhi kukhona nezinqamuleli ze-plasma eziphathwayo eziphathwayo ezisetshenziswa kumaworkshop wezandla. Umbuzo okufanele ucatshangelwe, nokho, ngowokuthi isiphi isinqamuli se-plasma esiphezulu, futhi yisiphi esilungele kangcono izinhloso zakho?

Izisiki ze-Plasma ziyimishini enamandla ekwazi ukusika insimbi, eminye ekwazi ngisho nokusika ezingxenyeni eziwugqinsi njengommese phakathi kwebhotela.

Umsiki we-plasma uyisisetshenziswa esibalulekile sabashiseli abaningi. Nokho, ngokumangalisayo, yenza okuphambene ncamashí nomshini wokushisela njengoba esikhundleni sokuhlanganisa izingcezu zensimbi, umshini wokusika i<em>plasma uzihlukanisa. Lokhu kuyadingeka njengoba ngesikhathi esithile ngesikhathi sephrojekthi yokushisela, kuyodingeka ukusika izingxenye ezingafuneki noma ukubumba insimbi ngendlela ethile.

Njengazo zonke izinto ezisembonini yokushisela, abasiki be-plasma bahlala beshintshashintsha, nemishini yokusika insimbi enamandla kakhulu ekhiqizwa ukusika izinsimbi eziqinile, futhi kunezelwa ezishintshayo. Kuyacaca ukuthi njengoba ukushisela kuyinqubo eyingozi, amarobhothi noma imishini esebenzisa i-CNC automation iphephile kunabantu bangempela, kodwa yiziphi izinzuzo nezingozi zomshini onjalo?

Kukhona abasebenzi abamelene nokusika okuzenzakalelayo futhi zombili izimpikiswano zinezici zazo ezinhle, kodwa ukuthi i-CNC (irobhothi) izothatha indawo yokushisela okuzenzakalelayo kusazobonakala.

Ake siqonde la mathuluzi amabili okusika ngokuya ngesimiso sokusebenza kwawo, izici zokusebenza, ukusetshenziswa, kanye nobuhle nobubi.

Okuqukethwe

Isisiki seplasma esiphathwayo esiphathwayo

Ithebula le-CNC le-plasma kanye ne-robotic plasma cutter

Ukuqhathaniswa kwama-CNC plasma cutters aphethwe ngesandla

Intengo nezindleko

Ukukhethwa

Isisiki seplasma esiphathwayo esiphathwayo

I-plasma cutter ephathwayo iyisakhiwo esihlangene futhi esingasindi esingathwalwa siye kunoma iyiphi indawo yomsebenzi, kungaba ngaphakathi noma ngaphandle. Uma usebenzisa i-plasma cutter ephathwayo ephathwa ngesandla, mane nje uxhume umoya ocindezelwe, ubambe ithoshi, bese uqala ukusika insimbi yeshidi, ishubhu, noma amaphrofayili ngemizuzwana.

Izimiso zesisiki seplasma esiphathwayo esiphathwayo

Izingxenye ezimbili eziyinhloko zomshini wokusika we-plasma obanjwe ngesandla ithoshi ne-chassis. I-arc kagesi ikhiqizwa phakathi kwe-nozzle (i-anode) kanye ne-electrode (cathode) ngaphakathi kwethoshi ehlanganisa umswakama phakathi ukuze kuzuzwe isimo se-plasma. Ngemva kwalokhu, isitimu se-ionized sikhishwa ku-nozzle ngesimo se-plasma beam ngomfutho wangaphakathi, obese wenza ukusika, ukushisela, nezinye izinhlobo zokwelapha ukushisa ensimbi.

Izici zesisiki se-plasma esiphathwayo esiphathwayo

Ukuphatheka okuphezulu

Ngenxa yokuphatheka kokugcina komsiki, i-compressor yomoya yangaphakathi iyakwazi ukusebenza ezindaweni lapho umoya ocindezelwe wangaphandle ungatholakali.

Ukulawula okukhiphayo okuqhubekayo

Ukulawula okukhiphayo okuqhubekayo kugxilisa i-arc yobukhulu obuhlukahlukene bezinto.

Isistimu yokuqala yokuthinta

Isistimu yokuthinta iqala i-arc ye-plasma ngaphandle kwesidingo samafrikhwensi aphezulu.

Ukushisa okusheshayo

Ukuthungela ngokushesha kunqamula izikhala, ngisho nalapho kusetshenziswa kunsimbi enwetshiwe.

Izilawuli zokuhlanza iphaneli yangaphambili

Izilawuli zokuhlanza iphaneli yangaphambili zivumela ukulungiselelwa okulula kwamazinga okugeleza komoya ngaphandle kokuvula i-arc ye-plasma.

Front panel purge control

I-front panel purge control system ivumela ukusetha okulula kwezinga lokugeleza komoya ngaphandle kokuqala i-plasma arc.

Ukusebenza okubandayo nempilo ende yezinto ezisetshenziswayo

Ngenxa yokusebenza kwayo okubandayo nempilo ende yezinto ezisebenzisekayo, idizayini entsha ye-electrode ne-nozzle ingakongela imali phakathi namahora amade okusebenza.

buhle

Isisiki se-plasma esiphathwayo, esiphathwayo samukela ubuchwepheshe be-inverter esezingeni eliphezulu futhi siveza izinzuzo zokuthi sihlangene, singasindi, futhi sibe sincane ngosayizi, sinokushisa kwe-arc okunemvamisa ephezulu, ukuthungela kwe-arc okulula, kanye nobude besikhathi somthwalo omkhulu. Ukwengeza, ngokusebenzisa umoya ocindezelwe oshibhile njengomthombo womoya wokusika, ungonga imali futhi uthuthukise ukusebenza kahle uma kuqhathaniswa nalapho usebenzisa umshini wokusika amalangabi. I-Cutting current (i-digital display) iyalungiseka ngokuqhubekayo, inembile, futhi inembile; futhi ifeni ilawulwa ngobuhlakani ukuze yonge amandla nogesi, kuyilapho inciphisa izinga lokuhluleka kwefeni.

Isisiki se-plasma esiphathwayo, esiphathwayo silungele ukusetshenziswa isikhathi eside, esindayo. Ngaphezu kwalokho, ayifanelekile kuphela ukusika okubanjwe ngesandla kodwa futhi nezinhlelo zokusika ezizenzakalelayo ezifana ne-CNC namarobhothi. Okokugcina, esinye isici okufanele sicatshangelwe ukuthi inokuxhumana kwe-analog nedijithali ukuhlangabezana nezidingo zokuxhumana zemishini yokushisela ezenzakalelayo.

bawo

I-plasma arc iveza into engazinzile engaholela ekulimaleni, njengokusikeka okungalingani nokwakheka kwesimila. Ukwengeza, kungaholela ekunciphiseni impilo yezingxenye ezihlobene.

I-engeli ye-bevel ohlangothini olulodwa lwendawo yokusika inkulu futhi iveza ukuma okungalungile.

Ngesikhathi sokusika, izinsalela eziningi zokusika zikhiqizwa endaweni yokusika. Ngenxa yalokhu, i-slag kufanele ibe phansi ngemuva kokusika, njengoba kungenjalo, izothinta ikhwalithi yenqubo, okuzokwandisa izindleko zabasebenzi.

Ukusika kwe-Plasma kunendawo enkulu ethintekayo ekushiseni kanye nomthungo obanzi wokusika, futhi njengoba insimbi ikhubazekile ngenxa yokushisa, ayifanele ukusika izinsimbi ezincane.

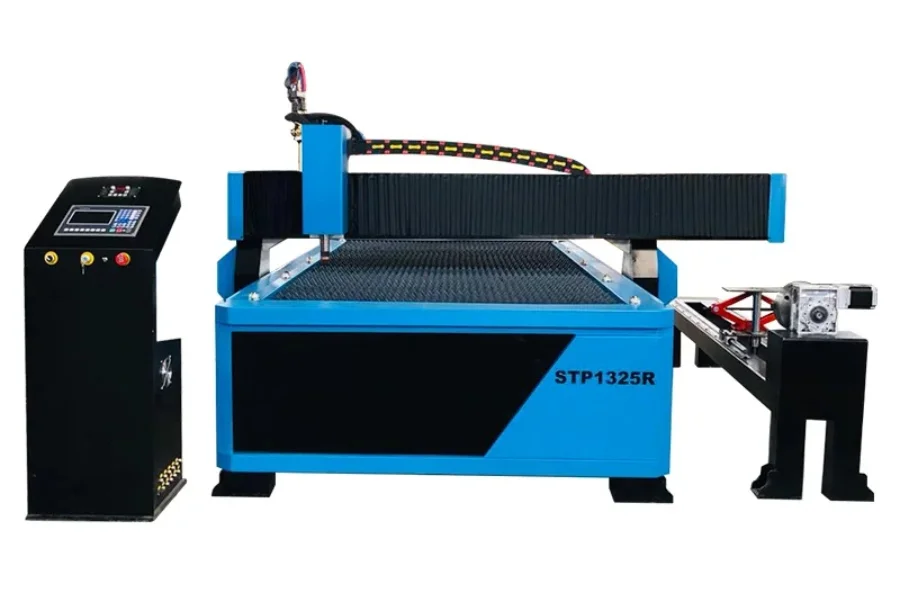

Ithebula le-CNC le-plasma kanye ne-robotic plasma cutter

Ithebula le-CNC le-plasma liyingcezu esebenza kahle, enembayo ephezulu, futhi enokwethenjelwa ephezulu ehlanganiswe nokunemba kokudluliselwa kwemishini kanye nobuchwepheshe bokusika okushisayo. I-interface yayo yomshini womuntu yenza imisebenzi ibe lula ukuze ikwenze kube lula. Ngenxa yalokhu, ingakwazi ukusika ngokushesha nangokunembile izimo ezihlukahlukene eziyinkimbinkimbi zamapuleti, okwenza ifaneleke ngokukhethekile ukusika okuzenzakalelayo kwezinsimbi. Iphinde inikeze ngedizayini edidiyelwe ehlanganisiwe ehlakaniphile futhi kulula ukuyisebenzisa.

Izimiso zetafula le-plasma le-CNC kanye ne-robotic plasma cutter

Ithebula le-plasma le-CNC lihlanganiswe nesilawuli se-CNC esilula nesisebenziseka kalula, esenza i-ionize ukugeleza komoya okunesivinini esikhulu okukhishwa emlonyeni kumazinga okushisa aphezulu ukuze kwakhe umqhubi. Uma ugesi usudlulile, igesi eqhubayo yenza i-arc ye-plasma enezinga lokushisa eliphezulu, ukushisa kwayo okubangela ukuthi insimbi ekusikeni kwengxenye incibilike kancane (futhi ihwamuke). Ukulandela lokhu, amandla okugeleza kwegesi ye-plasma enesivinini esikhulu asetshenziselwa ukususa insimbi encibilikisiwe ukwenza indlela yokucubungula.

Uma isebenza, igesi ecindezelwe njenge-nitrogen, i-argon, noma umoya-mpilo ithunyelwa ngeshubhu elincane futhi i-electrode engalungile ifakwa phakathi kweshubhu. Uma le electrode eyinegethivu inikwa amandla futhi umlomo wombhobho uthinta insimbi, kwakheka iluphu eqhubayo bese kukhiqizwa inhlansi kagesi enamandla amakhulu phakathi kwe-electrode nensimbi. Lapha, njengoba igesi ye-inert igeleza ngamashubhu, inhlansi ishisa igesi ize ifinyelele esimweni sesine sezinto. Le nqubo yokusabela ikhiqiza umfudlana we-plasma eshisa kakhulu nenesivinini esikhulu, engashintsha ngokushesha insimbi ibe i-slag encibilikisiwe.

I-plasma ngokwayo ine-current egeleza kuyo, futhi inqobo nje uma ama-electrode esebenza futhi i-plasma igcina ukuxhumana nensimbi, umjikelezo we-arcing uzohlala uqhubeka. Ukuqinisekisa lokhu kuthintana nensimbi ngenkathi ugwema umonakalo obangelwa i-oxidation nezinye izakhiwo ezingaziwa okwamanje, i-nozzle yomshini wokusika ifakwe enye isethi yamapayipi aqhubeka ekhipha igesi evikelayo ukuvikela indawo yokusika. Ngenxa yokucindezela kwaleli gesi elivikelayo, i-radius ye-columnar plasma ingalawulwa ngokuphumelelayo.

Izici zetafula le-CNC le-plasma kanye ne-robotic plasma cutter

Ugongolo lwetafula le-CNC plasma luthatha isakhiwo sokushisela ibhokisi ngenkathi ukwelashwa kokushisa kuqeda ingcindezi. Lesi sisiki silula futhi sinezici zokuqina okuhle, akukho ukuguquguquka, ukunemba okuphezulu, kanye ne-inertia encane.

Iziphetho ezimbili zohlaka lwedrayivu ye-longitudinal (uhlaka lokugcina) kulesi sinqamuli zifakwe amasondo omhlahlandlela ovundlile, ongalungisa izinga lokucindezela lesondo le-eccentric ngaphansi kohlaka lokushayela ukuya kumzila wesitimela, okusho ukuthi wonke umshini ungagcina umhlahlandlela ozinzile ngesikhathi sokunyakaza. Iphinde ifakwe umqoqi wothuli ukuze kukhawulwe imfucumfucu enqwabelene phezu komzila wesitimela.

Kokubili amadrayivu aqondile navundlile ashayelwa i-rack enembile kanye nephinikhodi. Umzila wesitimela ovundlile wamukela ipuleti likamhlahlandlela elidonswa ngokubanda elinembayo, ujantshi wesitimela welongitudinal wenziwe ngojantshi ocutshungulwe ngokunemba (ujantshi osindayo), futhi idivayisi yokunciphisa isebenzisa isinciphisi segiya elinembayo esingenisiwe. I-back-lash isusiwe ukuze kuqinisekiswe ukunemba kokunyakaza nokuzinza.

Ithebula le-CNC plasma liyonga futhi kulula ukulisebenzisa. Yamukela itafula lokusika elihlanganisiwe kanye ne-hopper eyamukelayo. Ngaphezu kwalokho, uma kudingeka, ingathatha indlela yokususa uthuli olomile noma isistimu yokususa uthuli ongayikhetha ukuze kuncishiswe intuthu namagesi ayingozi akhiqizwa umshini ngesikhathi sokusika.

Lesi sisiki se-plasma sinikeza uhlelo oluthuthukisiwe olulawulwa ngekhompuyutha, olunomsebenzi ongaxhunyiwe ku-inthanethi ngokuphelele, umklamo owenziwe umuntu, nezindlela zokusebenza ezilula nezisheshayo. Ngokusho kwenqubo yokusebenza, phansi kwesikrini sesistimu ye-CNC inikeza imisebenzi ehlukahlukene yokusebenza ekubonisweni okucacile, futhi imodi yamahhala yokuqeqesha inikezwa.

Umsiki usebenzisa umhlahlandlela kanye nendlela yokulungisa ngokushesha. Lokhu kusho ukuthi izinkomba zephutha ziboniswa esikrinini sesistimu yokulawula izinombolo futhi zonke izehlakalo zephutha zisobala lapho uthi nhla. Ukugcinwa komshini wonke kulula futhi kuyashesha futhi kwenziwa ngokulandela imiyalelo yephutha.

Ukwenza inqubo yokuhlanganisa ibe lula, u-opharetha uhlanganisa isithombe bese ekhetha inani lokusikwa kanye nesiqondiso sokuhlela ukuze enze ukusika okuqhubekayo nokuzenzakalelayo kanye nokuhlanganiswa okuphelele, ngaleyo ndlela ehlise umthwalo womsebenzi kubaklami.

Isofthiwe ithatha ubuchwepheshe bokukhiqiza beyunithi, okuthuthukisa ukuzinza nokuzwela kokusebenza kwemishini futhi inciphise izindleko zokulungisa kamuva.

Izesekeli ezivamile kanye nezingxenye zomshini nazo zingathengwa emakethe, ngaleyo ndlela kuncishiswe izindleko kumakhasimende.

Ithebula le-CNC lokusika i-plasma engaphansi kwamanzi lifakwe umbhede wamanzi wokusika ngaphansi kwamanzi, okunciphisa kakhulu ukungcoliswa kwemvelo okufana nentuthu, ukukhanya kwe-arc, amagesi ayingozi, nomsindo. Lokhu kusho umphumela omuhle wokuvikela imvelo.

buhle

Izinga elihle lokusika kanye nezindleko zabasebenzi eziphansi

Umshini wokusika i-plasma usebenzisa ukucubungula okungathinteki futhi awulimazi ucezu lokusebenza. Umkhiqizo osikiwe awunayo i-extrusion deformation futhi umkhiqizo ocutshunguliwe ungowekhwalithi enhle awunayo i-burr futhi asikho isidingo sokugaya kabusha ngesandla. Lokhu konga ezinqubweni zokucubungula ezingadingekile futhi kukhulisa ukusebenza namandla.

Yonga ekutshalweni kwesikhunta futhi unciphise izindleko zokukhiqiza

Imishini yokusika i-Plasma ingakha ngokuqondile izingcezu zensimbi ezihlukahlukene ngaphandle kokubunjwa noma ukusetshenziswa kwesikhunta futhi ngaphandle kwesidingo sokulungisa noma ukufaka esikhundleni sesikhunta. Lokhu kungasindisa futhi enanini lesikhunta esisetshenzisiwe, londoloza izindleko zokucubungula, futhi kunciphise izindleko zokukhiqiza, okwenza kube ngokufaneleka ngokukhethekile ukucutshungulwa kwemikhiqizo emikhulu.

Ukunemba okuphezulu ukuze kuthuthukiswe ngempumelelo ukukhiqiza

Ukusika i-plasma okuzenzakalelayo kuqhosha ngokunemba okuphezulu, ukusebenza kahle, nokuguquguquka, futhi kungacubungula ngempumelelo izingxenye ezahlukahlukene eziyinkimbinkimbi. Ukusika i-plasma okuzenzakalelayo kunciphisa isikhathi sokusika njengoba kudinga kuphela ukwenza i-graphic cutting futhi ingenise ohlelweni lokulawula, bese ubukhulu bungasethwa ukusika.

Isivinini sokusika esisheshayo kanye nendawo yokusebenza eyenziwe kahle

Kanye nokusika ngokushesha, ukusika kwe-plasma okuzenzakalelayo kuzinzile lapho kusebenza, umsindo uphansi, akukho uthuli, futhi ngeke kukhiqize izinto zamakhemikhali eziyingozi emzimbeni womuntu kanye nemvelo. Lokhu kutshalwa kwezimali kunikeza ukungcola okuncishisiwe, kukhuthaze ukwenziwa ngcono kwendawo yokusebenza, futhi kuhambisane negagasi lokuvikelwa kwemvelo.

Izindleko zokunakekela eziphansi kanye nokusebenza kwezindleko

Izindleko ezihilelekile ekugcinweni kwemikhiqizo yemishini ziphezulu kakhulu, kodwa ngenxa yokusebenza kwayo okuzinzile, i-plasma cutter ihlala isikhathi eside futhi ingasebenza ngokuqhubekayo ngaphandle kokulimala kalula. Lokhu kusho ukuthi umsiki we-plasma unezinzuzo ezinkulu ngokwezindleko zokuyilungisa kamuva.

bawo

Ukusika insimbi ewugqinsi kudinga ukunikezwa kwamandla aphezulu, okungabiza uma uthenga a umshini wokusika laser ngomthombo we-fiber laser. Ukusebenza nokugcina okokusebenza okuzenzakalelayo kubandakanya izingozi ezingaba khona futhi abaqhubi kufanele baqaphe ukuze bagweme ukulimala.

Uma izitho zomsebenzisi zithinta umshini onyakazayo, zingabhajwa futhi zilimale. Kodwa-ke, ama-opharetha angakwazi kalula ukugcina izandla nezinyawo zabo kude nomshini onyakazayo njengoba isistimu yekhompyutha elawulwa ngezinombolo ingasetshenziswa ukulawula isisiki kukhiphedi yephaneli yangaphambili noma isixhumi esibonakalayo esikude. Naphezu kwalokhu, lapho usebenzisa umshini, ungagqoki izingubo ezixegayo noma izingubo ezinezintambo ukuze zingabanjwa emshinini.

Umsiki we-plasma we-CNC unosongo lokukhipha amandla kagesi aphezulu angalimaza futhi abulale abantu. Ngakho, kufanele ifakwe ngokuhambisana nezinyathelo nezidingo ezishiwo umenzi.

Usetshenziswa

Ngokuvamile, izinqamuli ze-plasma eziphathwayo zisetshenziswa abantu abazithandayo kuyilapho amatafula okusika e-CNC plasma namarobhothi e-plasma asetshenziselwa ukusetshenziselwa ukuhweba kanye nokukhiqizwa kwezimboni. Kodwa-ke, zombili lezi zingasetshenziselwa amaphaneli okuvikela injini yezimoto, amakhabethe we-chassis, insimbi yengadi, imikhumbi yokucindezela, imishini yamakhemikhali, umoya omncane kanye nesiqandisi, ukukhiqizwa kweminyango yokuphepha, umshini, ukukhiqizwa kwabalandeli, imishini yokwakha, izakhiwo zensimbi, ukukhiqiza ubhoyela, ukwakhiwa kwemikhumbi, imishini ye-petrochemical, imishini yezimboni elula, i-aerospace, imikhumbi yokucindezela kanye nomhlobiso, ukukhiqizwa kwezimpawu ezinkulu, nokunye.

Bonke abasiki be-plasma namarobhothi bangakwazi ukusika insimbi ye-carbon steel (ukusika amalangabi), insimbi engagqwali, ithusi, i-aluminium (ukusika i-plasma), amashidi e-aluminium, amashidi anamathangi, amashidi ensimbi amhlophe, insimbi engagqwali, ishidi lethusi, namanye amapayipi ensimbi, kanye nokukwazi ukwenza imisebenzi yokusika nokuvala emaphrofayilini nasemashidini.

Ukuqhathaniswa kwama-CNC plasma cutters aphethwe ngesandla

Manje njengoba sesazi okwengeziwe ngalezi zinhlobo ezimbili zemishini yokusika i<em>plasma, singazibuza ukuthi ziyini ukufana nokuhluka kwazo. Esigabeni esilandelayo, sizoqhathanisa izici eziyisi-8 ukuze ukwazi ukwenza ukukhetha okufanele lapho unquma ukuthi iyiphi elungele ibhizinisi lakho.

Indlela yokuqala ye-arc

Kunezinhlobo ezimbili zokunikezwa kwamandla e-plasma, okuyi-contact arcing kanye ne-non-contact (inkinobho) arcing. Ukunikezwa kwamandla e-plasma okubanjwa ngesandla kubalwa ngendlela yokuqala ye-arc yokuxhumana. I-CNC plasma cutter, ngakolunye uhlangothi, kufanele isebenzise indlela yokuqala ye-arc engathinteki. Ukuze wahlulele ukuthi iyiphi imodi yokuqalisa i-arc okungokwakho amandla, vele uhlole inkinobho ekuthoshi lesandla. Ngokuvamile, izinsiza zikagesi ezinamamanje amakhulu kuno-100A izindlela zokuqala ze-arc ezingaxhunywanga.

Amandla kagesi

Ukunikezwa kwamandla e-plasma ephathwayo kunokuphazamiseka okunamandla ohlelweni lokulawula izinombolo, kuyilapho umthelela wokunikezwa kwamandla we-plasma olawulwa ngekhompuyutha useduze nokungabikho. Ezimweni ezimbi kakhulu, lokhu kungaholela ekuveleni kwesikrini esimnyama ohlelweni lokulawula izinombolo.

Isibani

Ithoshi ku-CNC plasma power supply iyisibhamu esiqondile, kuyilapho ithoshi eliseceleni likagesi le-plasma liyisibhamu esibambo esigobile.

Ukukwazi

Mhlawumbe umehluko osobala kakhulu phakathi kwe-automatic robotic plasma cutter kanye ne-manual cutter amandla akhiqizwa yilowo nalowo.

Izisiki ze-plasma ezenziwa ngesandla ngokuvamile ziyizisetshenziswa ezincane ezingasindi futhi kulula ukuzithwala kodwa ngenxa yokuthi azinawo amandla okukhiqiza ukushisa okungako, azikwazi ukukhiqiza amandla angaka.

Ngakolunye uhlangothi, ama-robotic plasma cutters ayimishini emile ekhiqiza ukushisa okuningi, okusho ukuthi imifudlana ye-plasma abayikhiqizayo ishisa ngempela.

Amakhono abanye be-CNC noma abasiki berobhothi awakwazi ukukalwa ngesandla.

I-CNC noma amarobhothi asetshenziswa ekukhiqizeni izimboni lapho enqamula amashidi ensimbi aminyene kakhulu. Ngaphezu kokusikwa, kungaba yingozi kakhulu kubantu ukuma eduze nokushisa okungaka. Ngenxa yalokho, abasiki be-plasma abazenzela bafaneleka kangcono kumaphrojekthi amancane futhi abantu bavamise ukuwasebenzisa endaweni yokusebenzela ngezinhlobo eziyisisekelo zokusika noma izinsimbi ezizacile.

ukuthwala

Sithinte isici sokuphatheka ngenhla. Ama-CNC plasma cutters ngokuvamile ayimishini emikhulu emile edinga ukuthi insimbi yeshidi isikwe ukuze ihlanganiswe emshinini. Ngakolunye uhlangothi, izisiki ze-plasma ezenziwe ngesandla azisindi futhi ziyaphatheka, okusho ukuthi zingayiswa ensimini ukuze zisebenze noma kuphi lapho zidingeka khona. Ukwengeza, banelungelo lokuguquleka kalula ezindaweni ezithile eziqinile, okunzima futhi kwezinye izimo akunakwenzeka nge-automatic plasma cutter.

Ukwenza kahle hle

Kunesinye isici okufanele sicatshangelwe mayelana nempumelelo yokusika i-CNC. Akekho ongasika ngokunembile ngomsiki we-plasma owenziwe ngesandla njengoba akwazi nge- Umshini we-CNC, njengoba lezi zihlelwe kakhulu futhi ziqondiswa kusetshenziswa isofthiwe yesimanje futhi umuntu akakwazi ukusika kafushane njengomshini. Ngakho-ke, abasiki be-plasma bezandla bangasebenza ngaphandle kokubheka ukunemba komkhiqizo.

Kweminye imisebenzi, ukunemba kubaluleke kakhulu kangangokuthi kungenzeka ukonakalisa ngephutha umkhiqizo wokugcina uma lokhu kwehluleka. Ngakho-ke, kubalulekile ukuthi i-plasma cutter isebenze kahle.

Intengo nezindleko

Uma ungumuntu othanda ukuzilibazisa, nakanjani uzofuna isisiki seplasma esiphathwa ngesandla. Ezinhle ngempela zithengisa cishe ngama- $ 1000 lilinye, okuyinani elithengekayo kumshiseli omuhle owenza umsebenzi egaraji noma ojabulela nje ukusebenza kumaphrojekthi we-DIY.

Ngakolunye uhlangothi, abasiki be-plasma be-CNC babiza ngempela, ngezindleko ezingaphezulu kuka-$8,000 iyunithi ngayinye. Njengoba sihlome ngalolu lwazi, kuphephile ukusho ukuthi amarobhothi awusizo kuphela ezinkampanini ezinkulu ezidinga ama-automatons. Ukwengeza, izinkampani ezincane azikwazi njalo ukukhokhela i-CNC ebizayo noma i-robotic cutter ngakho-ke kufanele zinamathele kumsiki wezandla.

Ukukhethwa

Ngakho, yiziphi iziphetho ezingafinyelelwa kulesi sihloko?

Empeleni, i-plasma cutter ephathwayo iyisinqumo esihle semisebenzi elula. Inamandla ngokwanele ukusika amashidi ensimbi azacile noma anokuqina okumaphakathi futhi ifanele noma yiluphi uhlobo lwephrojekthi egaraji noma eduze kwendlu. Futhi, iwusizo kakhulu emsebenzini wasensimini.

Uma kuziwa kubasiki be-plasma be-CNC abazenzakalelayo, benzelwe umsebenzi onzima. Izimboni ezidinga ukunemba kanye nokusebenza zizohamba kunoma ibuphi ubude ukuze zithenge enye yalezi.

Ekugcineni, ukukhetha kuzokwehla ekusebenzeni nokunemba, kanye nokukwazi ukukhokhela nokuvumelana nezimo.

Umthombo ovela stylecnc.com

Umshwana wokuzihlangula: Ulwazi olubekwe ngenhla luhlinzekwa yi-stylecnc ngaphandle kwe-Cooig.com. I-Cooig.com ayenzi izethulo namawaranti mayelana nekhwalithi nokuthembeka komdayisi nemikhiqizo.