Abakhiqizi bavame ukudinga izinqubo zokukhiqiza ezenziwe ngezifiso nezithembekile zemikhiqizo yabo. Ubuchwepheshe be-laser buthuthuke kakhulu ukuze bunikeze ukusebenza okuphezulu kwe-laser welding, ukuqopha, kanye nemishini yokusika enciphisa isikhathi sokukhiqiza ekuphenduleni izimfuno ezivela embonini yomhlaba wonke.

Lesi sihloko sizoxoxa kuqala ngemakethe yomshini we-laser yezimboni enamandla ngaphambi kokuchaza izinhlobo ezahlukene zemishini ye-laser yezimboni kanye nezitayela ezivame kakhulu eNingizimu-mpumalanga ye-Asia.

Okuqukethwe

Ukubuka konke kwemakethe yomshini we-laser yezimboni ngo-2023

Izinhlobo zemishini ye-laser yezimboni

Izitayela eziphezulu zemishini ye-laser yezimboni eNingizimu-mpumalanga ye-Asia

Buka lawa mathrendi

Ukubuka konke kwemakethe yomshini we-laser yezimboni ngo-2023

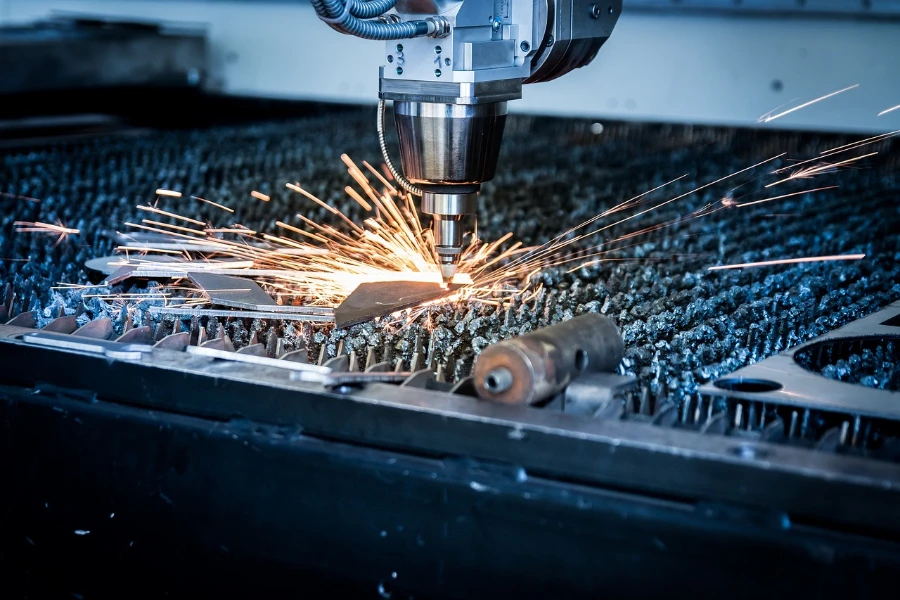

Imakethe yemishini yokusika i-laser yalinganiselwa ku-USD 6,832.8 billion ngo-2022, futhi ukusuka ngo-2023 kuya ku-2030, ingakhula ngesilinganiso sokukhula sonyaka esihlanganisiwe (CAGR) esingu-5.5%. Isidingo esandayo semboni yokusetshenziswa kokuphela kanye nokwenyuka kokuzenzakalelayo emkhakheni wezokukhiqiza kulindeleke ukuthi kukhuphule isidingo sokusika i-laser esikhathini sokubikezela, ukusekela ukwanda kwemakethe yomshini wokusika i-laser.

Izimboni ezisasetshenziswa kakhulu njenge-HVAC, ezezimoto, nezogesi zisebenzisa kakhulu lawa madivayisi ukukhiqiza izimpahla zekhwalithi ephezulu kahle. Ngenxa yokunemba kwemishini nokufana kwemiphumela yabo, abakhiqizi batshala imali ku-automation ukusika kwe-laser, kuthuthukisa ukukhula kwemakethe.

Ukuvela kwe-fiber laser cutting kuzophinde kusekele ukwanda kwemakethe. Imisebenzi eminingi yokucubungula ama-macro edinga ukunemba kwezinga lemilimitha, njengokusika nokushisela izinsimbi zezimboni, ihilela ukusebenzisa amadivaysi okusika i-fiber laser. Amandla emakethe okucubungula okukhulu abaluleke kakhulu kunokucubungula okuncane ngenxa yesidingo esikhulu semishini ye-laser.

Izithiyo ezinkulu ekwandeni kwemakethe zifaka amanani aphezulu, ukusetshenziswa kwamandla okuphezulu, izindleko eziphezulu zezingxenye zomshini nokugcinwa kwawo kusesimweni esihle, kanye nokukhishwa kwamagesi anobuthi njengegesi ye-phosgene.

Izinhlobo zemishini ye-laser yezimboni

Imishini yokushisela i-laser

Uhlobo olulodwa lwe imishini yokucubungula i-laser esetshenziselwa ukushisela nokusika insimbi i-laser welder. Lesi siqeshana somsebenzi sithola umjovo wamandla ophuma ku-laser beam, encibilika futhi iqine ngokushesha futhi inciphise ukuhlanekezela ngemva kokushisela.

Ama-Lasers anomthamo omkhulu wamandla. Ngamanye amazwi, bangakwazi ukugxilisa konke ukushisa kwabo ngqo kumthungo, bathuthukise isimo sezinto ezizungezile, uma kuqhathaniswa nemishini yokushisela evamile.

I-laser welding ihlanzeke ngendlela emangalisayo futhi ayidingi ukugaywa noma ukugaywa ngemuva. Lawa maweld wobuhle aphinde anikeze imikhiqizo yabasebenzisi bokugcina ukubukeka kweprimiyamu futhi adale okuvelayo kokuqala okujabulisayo.

Ukushisela nge-laser kushesha ngokuphindwe izikhathi ezinhlanu kuya kweziyishumi kunezindlela zokushisela zendabuko, okusho ukuthi isikhathi sokushintsha ngokushesha kanye nokwanda kokukhiqiza, ngaphandle kokuncipha kokucutshungulwa kwangemuva.

Ukuguquguquka kwalo mshini kungokwesibili. Noma yini nayo yonke into ingashiselwa kusetshenziswa ukusethwa kwe-laser okuhlukahlukene, okuhlanganisa amapuleti ensimbi asindayo embonini yezokuthutha, izinsimbi eziyigugu zobucwebe, izinsimbi ezihlukene njenge-aluminium nensimbi, noma othintana nabo bethusi bamabhethri emoto kagesi. Ngisho nezitsha zobumba zokushisela, ikilasi lezinto ezaziwa ngokuba nzima ukuzishisela, ziye zaphumelela ekuhloleni.

Zonke lezi zinzuzo zinenani nokho. Ukusetha i-laser kungabiza kabili noma kathathu ngaphezu kwamasistimu avamile. Kodwa-ke, intengo ngeyunithi ngayinye iyehla, futhi utshalomali luletha izinzuzo uma umthamo uphezulu.

The emakethe Imishini yokushisela nge-laser izokhula ku-CAGR ka-4.73% phakathi kuka-2021 no-2025, ifinyelele ku-USD 373.97 wezigidi ekupheleni kwesikhathi sokubikezela ngokuya ngezinhlobonhlobo zokusetshenziswa.

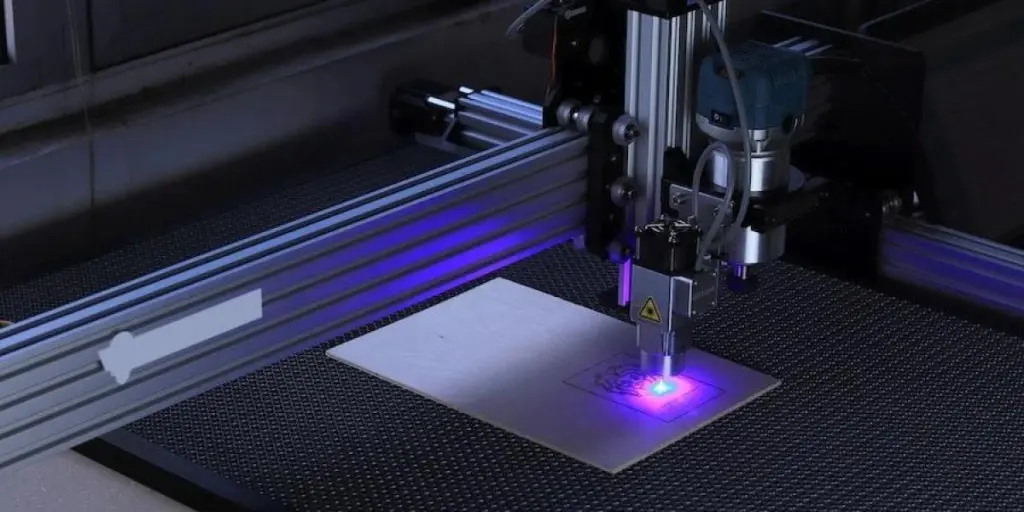

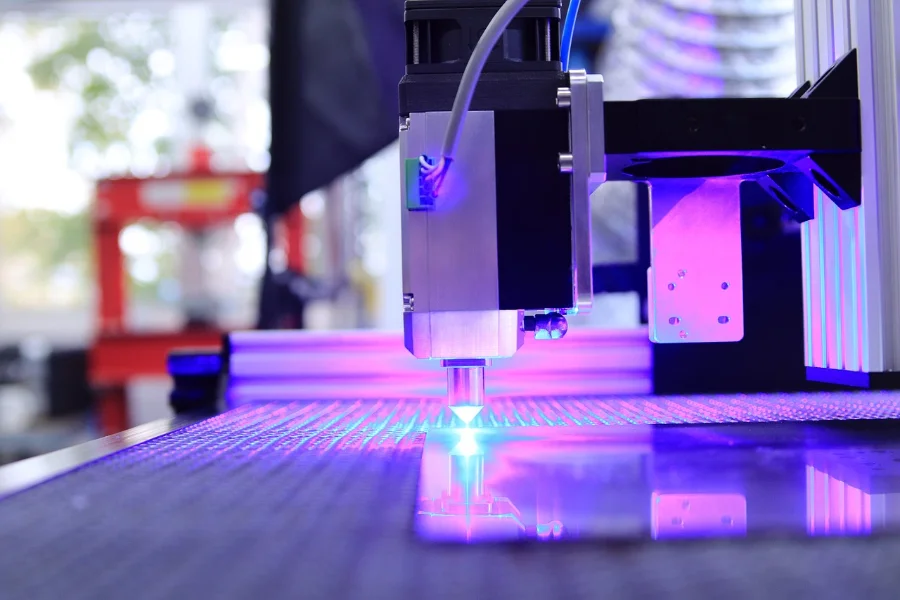

Imishini yokuqopha i-laser

Onjiniyela manje sebengakwazi ukukhiqiza izinhlamvu, izinombolo, noma izithombe ngaphandle kokufaka izingxenye zabo engozini umbhalo we-laser. Le ndlela isebenzisa ukukhanya kwe-laser okugxilile ukuze kwakhe amamaki angenawo umonakalo futhi afundeka kalula esikhundleni sokuqopha phezulu noma ukuthumela uyinki ngethuluzi elibonakalayo.

Lawa madivayisi ukusika nokuqopha ngokuzenzakalelayo izinto ezihlukahlukene, njengensimbi, ukhuni, ingilazi, nepulasitiki, ngokunemba okuqondile.

Ayisebenzisi izinto ezisetshenziswayo futhi ngenxa yalokho iluhlaza, ayibizi, futhi iyonga amandla uma iqhathaniswa nezinto ezisetshenziswayo ezifana noyinki namakhemikhali asetshenziswa kwezinye izinqubo zokumaka, abizayo futhi anomthelela omubi endaweni ezungezile. Ukumaka nge-laser, esikhundleni samalebula, kunikeza ukuhlonza okungapheli kwezingxenye futhi akudingi ukusetshenziswa okuphindaphindiwe.

Imvelo yokungathinteki yokumaka nge-laser iqinisekisa indawo yokucubungula ehlanzekile, engcoliswe kancane. Inqubo engenamonakalo kancane kuphela noma ayingeni ezintweni, ngokungafani nezinhlelo zokuphrinta ezizoshisa izinto ngokumaka.

Ukudweba kwe-Laser futhi kusiza abakhiqizi ukuthi bathobelane nemithetho ephakamisa ikhwalithi, ukulandeleka, nezinye izindinganiso zokuphepha, ezidingwa izinhlangano zikahulumeni, imboni yezimoto, ezemithi, ezondiza, nezinye izimboni ezibucayi.

Ngokwezibikezelo zomhlaziyi wemakethe, imakethe yokuqoshwa kwe-laser kulindeleke ukuthi inwebe ku-CAGR ka-4.93% ukusuka ngonyaka ka-2017 kuya ku-2030.

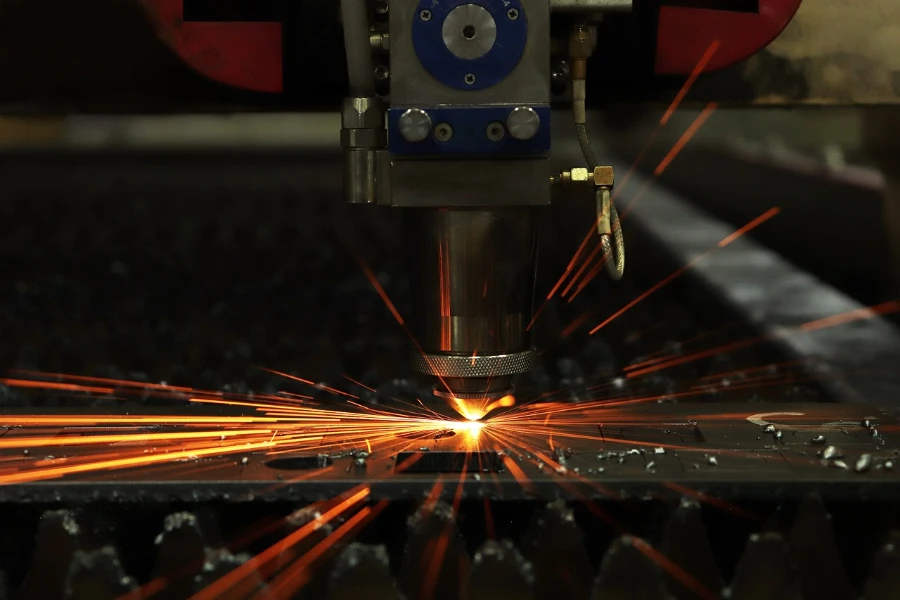

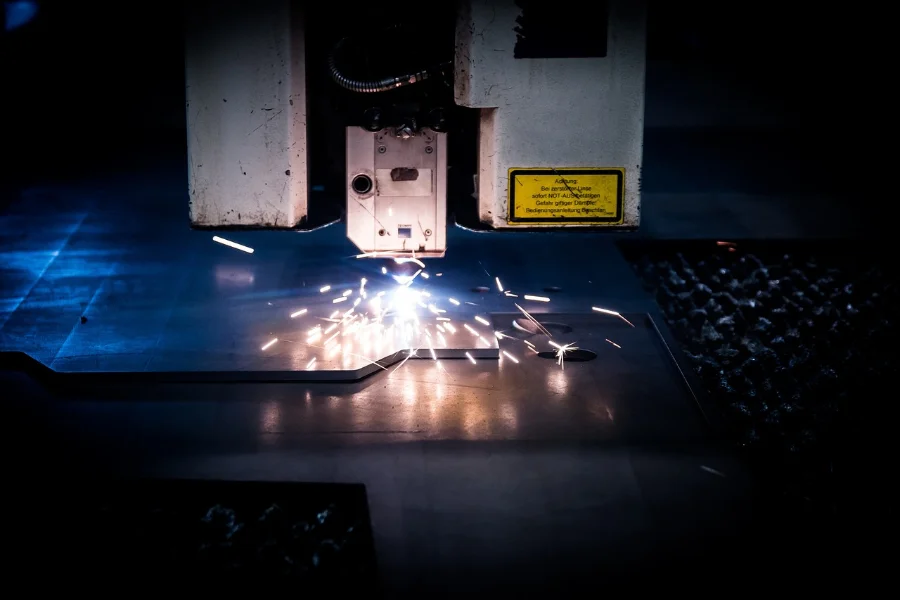

Imishini yokusika i-laser

Imishini yokusika i-laser zisetshenziswa ezimbonini ezihlukahlukene ukuze ukusika okunembile kanye nomklamo project. Ngosizo lwe-laser beam enamandla, lo mshini ungasika noma unamathisele umklamo oyifunayo ube izinto ezifana nensimbi, ipulasitiki, noma ukhuni.

Ama-Laser cutters ahlukahlukene. Ukushintsha amathuluzi okusikeka okuhlukile noma okuyinkimbinkimbi akudingekile. Ukusetha okufanayo kungasika amajamo amaningi ukusuka kugqinsi lwezinto ezifanayo. Ngokwemvelo, leli khono lincike emandleni alo.

Ukusika kwe-Laser thermal kuyashesha futhi kunembe kakhulu kunezinye izindlela zokusika ezishisayo, njenge-plasma noma ilangabi, ukusika kuze kube ukujiya okungaba ngu-10 mm. Ikhono lomsiki we-laser ekugcineni linquma iphuzu elinembile lenzuzo. Ukunemba okuphezulu kungafinyelelwa ngaphandle kokwelashwa kwangemva kokwelashwa ngokunemba okungu-+/-0.1 mm, futhi izinga eliphezulu kangako lisho ukuthi akukho ukubekezelela okwengeziwe okudingekayo. Izingxenye ezicishe zifane ncamashí enye kwenye iqinisekiswa ngo-+/- 0.05 mm.

Ubuchwepheshe besimanje bokusika i-laser buzenzakalela kakhulu, budinga umsebenzi omncane womuntu. Umkhiqizo wokugcina usazuza kakhulu ku-opharetha womshini onesipiliyoni. Noma kunjalo, le ndlela yokusika ibiza kancane kunezinye ngenxa yejubane lokusika kanye nomzamo omncane odingekayo womuntu.

Phakathi kuka-2020 no-2024, kuzoba nokunyuka kwe-USD 1.02 billion emakethe imishini yokusika laser, futhi ukukhula kwemakethe kuzokhula ngesivinini ngalesi sikhathi.

Izitayela eziphezulu zemishini ye-laser yezimboni eNingizimu-mpumalanga ye-Asia

Izitayela zemishini ye-laser yezimboni zezimoto

Imboni yezimoto yaseNingizimu-mpumalanga ye-Asia isebenzisa imishini ye-laser ukuthuthukisa izinqubo zokukhiqiza, ukuthuthukisa ukusebenza kahle, kanye nokuzuza ukunemba okuphezulu ekukhiqizeni izimoto. Ngenxa yalokho, imboni igcwele izitayela eziningi ezithuthukisa inzuzo yomshini we-laser.

Isibonelo, imboni yezimoto yaseNingizimu-mpumalanga ye-Asia isebenzisa amalaser anamandla amakhulu ukusika izinto ezihlukene ezihambisana nomkhakha wezimoto, njengamashidi ensimbi, izinhlanganisela, namashubhu. Ngaphezu kwalokho, isebenzisa imishini yokushisela i-laser enamandla ukuze ijoyine lezi zingxenye zensimbi futhi ujabulele ukulawula okunembe kakhudlwana.

Kodwa akugcini lapho. Izinqubo zokukhiqiza okungeziwe okususelwa ku-laser nazo ziyathrenda embonini. Izinhlobo ezifana ne-selective laser melting (SLM) kanye ne-laser sintering zingakhiqiza izingxenye zezimoto eziyinkimbinkimbi ngokuqondile kusukela kumamodeli e-3D CAD.

Imishini yokwelapha i-laser surface, enye inkambiso esekwe nge-laser, ingashintsha kalula izakhiwo ezingaphezulu zezingxenye zezimoto. Isibonelo, i-laser texturing ingakha amaphethini athile noma ukuthungwa kokubunjwa, ukuthuthukisa impilo ende nokusebenza.

Izitayela zemakethe zomshini we-Metal processing laser

Imboni yokucubungula insimbi isebenzisa kakhulu izimboni imishini ye-laser ngenxa yokunemba kwazo, isivinini, nokuguquguquka. Njengezinye izimboni, ubuchwepheshe be-laser bunikeza izinzuzo ezihlukahlukene, okuhlanganisa ukusika, ukushisela, ukumaka, nokuqopha.

Kodwa-ke, umkhuba owodwa ogqamayo ukuhlanza nge-laser. Le mishini ye-laser yezimboni ingakwazi ukususa kalula ukungcola, ama-oxide, upende, ukugqwala, nokunye okunamalebe endaweni yensimbi. Baphinde banikeze indlela yokuhlanza engathinteki futhi enobungani bemvelo ngaphandle kokusebenzisa amakhemikhali noma izinto ezilimazayo.

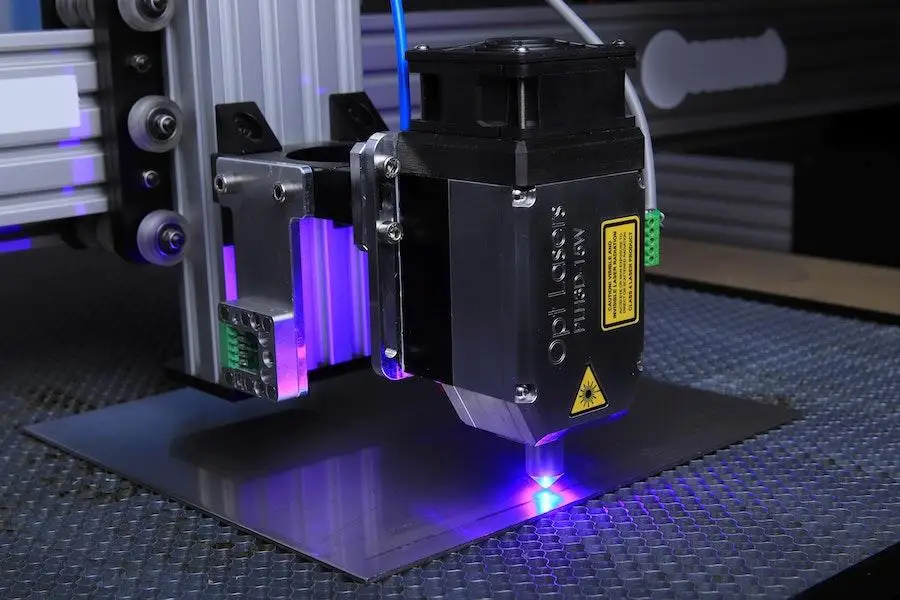

Amathrendi emakethe yomshini we-laser we-Diode

Ubuchwepheshe be-diode obukhipha ukukhanya kanye ubuchwepheshe be-laser diode zombili zisetshenziswa kabanzi kuma-laser pointers. Nakuba ukusika insimbi ngamalaser e-diode ekuqaleni kwakuyinselele, ukuthuthuka kwezobuchwepheshe kwawushintsha unomphela imboni. Idivayisi ye-Direct Diode Laser (DDL), noma i-laser yomjovo, ihlanganisa ukukhanya okuvela kuma-diode amaningana kube yibhamu eyodwa.

Ama-laser we-diode ingasetshenziswa ezindaweni ezicwebezelayo njengethusi ne-aluminium, izenze zisebenze kangcono kune-fiber lasers. Ijubane lokusika lishesha ngo-100% ngoba i-aluminiyamu imunca kalula ubude begagasi belaser ye-diode. Ukwengeza, imishini ye-diode enamandla amakhulu ingacubungula izinsimbi ngokushesha ngo-10-20% kune-fiber lasers. Baphinde banikeze ikhwalithi engcono yonqenqema uma usebenza ngezinto eziminyene.

Izitayela zemakethe yomshini we-CO2 laser

I-carbon dioxide (CO2) ama-laser sika futhi uqophe izinto ezihlukahlukene usebenzisa i-laser beam eyakhiwe kusuka ku-CO2, yingakho igama. Ingenye yama-lasers asetshenziswa kakhulu ngenxa yamandla ayo okusika aphakeme, ukunemba, kanye nesivinini sokusika esisheshayo. Izimboni zemithi, ezipakisha ukudla, nezikagesi zisebenzisa kakhulu I-CO2 laser ubuchwepheshe obunezinsimbi nezinto eziningi ezingezona izinsimbi njengokhuni nepulasitiki.

Ama-Lasers ayindlela enhle kakhulu yokusika izinto ezijiyile ngoba azibhoboza ngokushesha futhi akhiqize isiphetho esibushelelezi. Ama-lasers we-CO2 zibiza kancane kodwa zisebenzisa amandla angaphezu kwefayibha, okuphakamisa izindleko zokusebenza. Nokho, lokhu kuncike emandleni.

Uhlobo lwe-laser, imboni yokusetshenziswa kokuphela, kanye nejografi kunikeza umbono ongcono wesimo samanje sobuchwepheshe emakethe yomhlaba wonke ye-CO2 laser. Izinhlobo zamanje ze-laser ziwukugeleza okuphambene, okuvaliwe, namalaser egesi e-CO2 agelezayo. Kuzo zontathu, isidingo samalaser egesi e-CO2 agelezayo sibonisa izithembiso eziphezulu zokukhula okusheshayo kwe-CAGR.

Izitayela zemakethe yomshini we-fiber laser

I-Fiber lasers zingamathuluzi okusika insimbi akhethekile anejubane elingenakuqhathaniswa, ukunemba, nokuphindaphinda. Ngokuvamile, bangakwazi ukusika izinsimbi ezingezona ayoni kanye nensimbi emnene nengenasici. Le mishini ingasethwa ukuze isike izinsimbi eziwugqinsi futhi inikwa amandla yimithombo ye-laser engu-500W+ Fiber-Optic.

Imishini ye-fiber laser isebenza kahle kakhulu ekumaka okufana ne-annealing, etching, kanye nokuqopha. Ngenxa yobubanzi bawo obuncane bokugxila, lawa ma-laser asebenza kahle kakhulu ekumaka ulwazi olufana nezinombolo, ama-matrices edatha, namabhakhodi ezinsimbi. Ama-fiber lasers asetshenziswa ngokuyinhloko ukumaka ingxenye eqondile ukuze kusekelwe ukulandeleka komkhiqizo kanye nezidingo ezifanayo zokuhlonza.

Uma kuqhathaniswa namalaser e-CO2, i-fiber lasers i-eco-friendly, iyonga kakhulu amandla, asikho isidingo sokuyinakekela, futhi ihlala isikhathi eside, okusho ukonga ngokwezimali okubalulekile. Isidingo sama-fiber lasers sokuhlanza izinhlelo zokusebenza siyakhula. Izimboni eziningi zisebenzisa imishini yokuhlanza i-laser ukusiza ukususa ukungcola njengopende, ama-oxides, nokugqwala ezinsimbi.

Buka lawa mathrendi

Imakethe yomshini we-laser ilokhu ishintsha ngenxa yentuthuko eqhubekayo yezobuchwepheshe. Amabhizinisi angakhiqiza imiphumela emihle ngezinga elingakaze libonwe ngenxa yokunemba namandla emishini ye-laser.

Amathrendi akamuva emakethe akhombisa ukuthi i-CO2 ne-fiber lasers yizinketho ezidumile ngenxa yokusebenza kwazo okuthuthukisiwe. Ama-laser diode aqondile azoba ne-CAGR ephezulu kakhulu esikhathini esizayo ngenxa yokuthuthukiswa kwamandla awo okubamba, ukusevisa okulula, ukuthembeka okukhulayo, kanye nezindleko zokusebenza ezincishisiwe.

Abathengisi bangagxila kulokhu umshini we-laser wezimboni izitayela zokuthuthukisa ukuguquguquka, ukunciphisa izindleko zenqubo, nokwenza ukukhiqiza kusebenze kangcono.