Kusukela ngo-2024, imakethe yemishini yokushisela kagesi yomhlaba wonke, okuhlanganisa nabashiseli be-TIG, kulindeleke ukuthi ikhule ku-CAGR ka-7.81%, ifinyelele ku-USD 9.35 billion ngo-2030. Lokhu kukhula kubangelwa ukwanda kwesidingo sokunemba kokushisela ezimbonini ezihlukahlukene. Kubathengi bebhizinisi, ukukhetha isishiseli esifanele se-TIG kubalulekile ukuze kuhlangatshezwane nezidingo ezithile zamakhasimende abo nokuqinisekisa ukushisela kwekhwalithi ephezulu.

Okuqukethwe:

- Ukuqonda Ukubaluleka Kwabashiseli be-TIG Embonini Yemishini

- Izinto Ezibalulekile Okufanele Zicabangele Lapho Ukhetha I-TIG Welder

- Izinhlobo ze-TIG Welders kanye nezicelo zabo

- Amathrendi asafufusa ku-TIG Welding Technology

- Ukuhlola Izindleko Eziphelele Zobunikazi Zabashiseli be-TIG

- Ukuhlanganisa

Ukuqonda Ukubaluleka Kwabashiseli be-TIG Embonini Yemishini

Izicelo Ezibalulekile ze-TIG Welding emikhakheni Ehlukahlukene

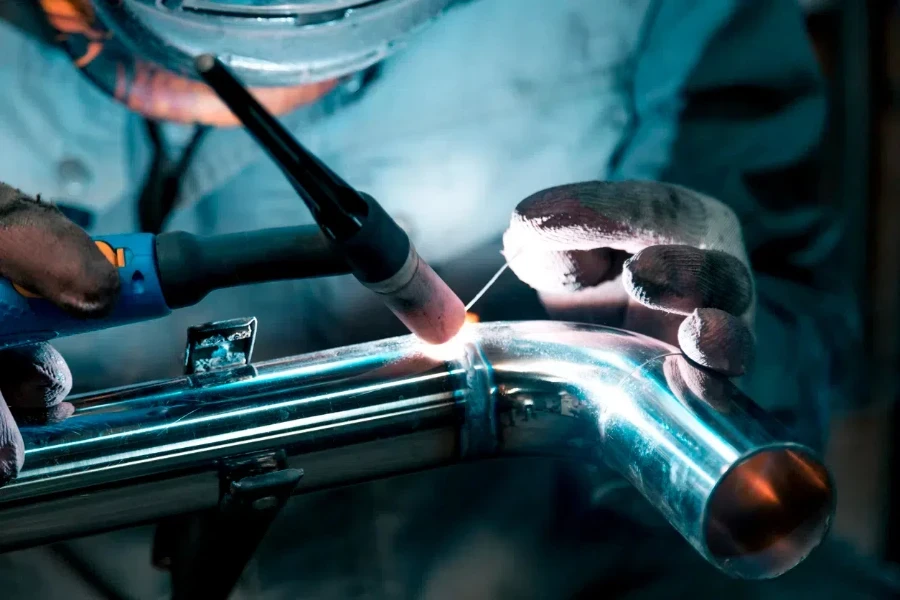

Ukushisela i-TIG, noma i-Tungsten Inert Gas welding, ibalulekile emikhakheni edinga ukunemba okuphezulu nokushisela okuhlanzekile. Embonini ye-aerospace, i-TIG welding isetshenziswa kakhulu ngekhono layo lokukhiqiza ama-welds asezingeni eliphezulu, angenasici ezintweni ezincane. Lokhu kunemba kubalulekile kubuqotho besakhiwo sezingxenye zendiza. Imboni yezimoto iphinde ithembele kakhulu ekushiseleni kwe-TIG ukuze kuhlanganiswe izingxenye ezibalulekile, njengamasistimu e-exhaust kanye nezingxenye ze-chassis, lapho amandla nokuqina kubaluleke kakhulu.

Embonini yemishini yezokwelapha, ukushisela kwe-TIG kubalulekile ngenxa yekhono layo lokwakha amashisela ahlanzekile, angangcoli. Lokhu kubalulekile ekuqinisekiseni ukuphepha nokusebenza kwamathuluzi ezokwelapha nezifakelo. Ukwengeza, imboni yokudla neziphuzo isebenzisa i-TIG yokushisela ukwenza imishini yensimbi engagqwali, okumele ihlangabezane nezindinganiso eziqinile zokuhlanzeka. Ikhono lokukhiqiza ama-welds abushelelezi, angenamifantu kusiza ukuvimbela ukukhula kwamagciwane, ukuqinisekisa ukuthobela imithetho yezempilo.

Umkhakha wezokwakha uzuza ekusebenzisaneni okuhlukahlukene kwe-TIG ekuhlanganiseni izinsimbi ezihlukahlukene, okuhlanganisa i-aluminium nensimbi engagqwali. Leli khono liwusizo ikakhulukazi ezinhlelweni zezakhiwo lapho ikhwalithi yobuhle nobuqotho besakhiwo kokubili kubalulekile. Ngaphezu kwalokho, i-TIG welding isetshenziswa ekukhiqizeni imikhumbi yokucindezela kanye namapayipi, lapho izinga lokushisela lithinta ngokuqondile ukuphepha nokusebenza.

Ukukhula kanye Nesidingo sabashiseli be-TIG Emhlabeni Wonke

Isidingo somhlaba wonke sabashiseli be-TIG siyakhula, siqhutshwa ukwanda kwezimboni ezibalulekile namaphrojekthi engqalasizinda. Ngokohlaziyo lwakamuva lwemakethe, imakethe yomshini wokushisela kagesi, ehlanganisa abashiseli be-TIG, ikhule isuka ku-USD 5.52 bhiliyoni ngo-2023 yaya ku-USD 5.93 billion ngo-2024. Lokhu kukhula kulindeleke ukuthi kuqhubeke ngezinga lokukhula lonyaka elihlanganisiwe (CAGR) lika-7.81%, lifinyelele ku-USD 9.35 billion ngo-2030.

Esifundeni sase-Asia-Pacific, amazwe afana neChina, India, kanye neJapan abona ukukhula okukhulu emakethe yokushisela ye-TIG. Lokhu kubhebhezelwa imiklamo emikhulu yengqalasizinda, imboni yezimoto ethuthukayo, kanye nomkhakha wezokukhiqiza othuthukayo. Izindlela ezintsha zobuchwepheshe bokushisela kanye nokutshalwa kwezimali okwandayo ocwaningweni nasekuthuthukisweni kwesifunda kuholele ekukhiqizweni kwezixazululo zokushisela ezisebenza kahle kakhulu nezingabizi, okuqhubekisela phambili ukukhula kwemakethe.

AmaMelika, ikakhulukazi i-United States, nawo amele imakethe enkulu yabashiseli be-TIG. Imikhakha yezimboni eqinile, okuhlanganisa ezezimoto, ezokwakha, nezokukhiqiza, ziyizisusa ezibalulekile zesidingo. Ukwamukelwa kobuchwepheshe bokushisela obusezingeni eliphezulu, obufana nezinhlelo ezizenzakalelayo kanye ne-semi-automated, kuthuthukisa ukusebenza kahle nokukhiqiza, okunomthelela ekwandeni kwemakethe. Ukwengeza, amaphrojekthi wengqalasizinda kanye nokuthuthukiswa komkhakha wamandla eCanada naseBrazil kubhebhezela isidingo semishini yokushisela ye-TIG.

Izinto Ezibalulekile Okufanele Zicatshangelwe Lapho Ukhetha I-TIG Welder

Okuphumayo kwamandla kanye ne-Amperage Range

Uma ukhetha i-TIG welder, ukuphuma kwamandla kanye nobubanzi be-amperage yizici ezibalulekile okufanele zicatshangelwe. Amandla aphumayo anquma ikhono lomshiseli lokusingatha ugqinsi oluhlukahlukene lwezinto. Isibonelo, i-welder enobubanzi obuphezulu be-amperage ingashisela izinto eziwugqinsi, iyenze ifanelekele izinhlelo zokusebenza ezinzima. Ngokuphambene, uhla lwe-amperage oluphansi lulungele izinto ezincane, eziqinisekisa ukunemba nokulawula.

Ububanzi be-amperage buphinde buthinte ukuguquguquka kwe-welder. Ibanga elibanzi le-amperage livumela i-welder ukuthi isetshenziselwe uhla olubanzi lwezinhlelo zokusebenza, kusukela ezintweni ezithambile nezincane kuya kweziqinile, izinsimbi eziwugqinsi. Lokhu kuvumelana nezimo kunenzuzo ikakhulukazi ezimbonini ezifana ne-aerospace neyezimoto, lapho izingxenye ezihlukene zidinga ukucaciswa kokushisela okuhlukahlukene. Ukwengeza, ikhono lokulungisa i-amperage liqinisekisa ngokunembile ikhwalithi yokushisela futhi linciphisa ubungozi bokukhubazeka.

Ngaphezu kwalokho, uhlobo lomthombo wamandla, noma ngabe i-AC noma i-DC, ludlala indima ebalulekile ekusebenzeni komshiseli. Amandla e-AC ajwayele ukusetshenziselwa ukushisela i-aluminium ne-magnesium, kuyilapho amandla e-DC ekhethwa njengensimbi yokushisela nensimbi engagqwali. Ukuqonda izidingo ezithile zezinto ezishiselwe kubalulekile ekukhetheni amandla okukhipha amandla afanele kanye nobubanzi be-amperage, ukuqinisekisa ukushisela okusebenzayo nokusezingeni eliphezulu.

Amandla e-AC/DC kanye Nezinzuzo zawo

Amandla we-AC/DC we-TIG welder isici esibalulekile esithuthukisa ukuguquguquka nokusebenza kwayo. I-AC (Alternating Current) isetshenziselwa kakhulu ukushisela izinsimbi ezingezona ayoni njenge-aluminium ne-magnesium. I-alternating current isiza ukuphula isendlalelo se-oxide ebusweni balezi zinsimbi, iqinisekise ukushisela okuhlanzekile nokuqinile. Leli khono libalulekile ezinhlelweni zokusebenza ezimbonini ze-aerospace nezezimoto, lapho i-aluminium ivame ukusetshenziswa khona.

I-DC (Direct Current), ngakolunye uhlangothi, isetshenziselwa ukushisela izinsimbi ezisansimbi njengensimbi nensimbi engagqwali. I-DC welding ihlinzeka nge-arc ezinzile kanye nokungena okujulile, okuyenza ilungele izinto eziwugqinsi. Amandla okushintsha phakathi kwezindlela ze-AC ne-DC avumela abashiseli ukuthi baphathe inhlobonhlobo yezinto zokwakha kanye nezicelo, bakhulise ukusetshenziswa kwabo ezimbonini ezahlukahlukene. Lokhu kuvumelana nezimo kunenzuzo ikakhulukazi ekukhiqizeni nasekwakheni, lapho amaphrojekthi ahlukene angase adinge ukushiselwa kwezinhlobo ezahlukene zezinsimbi.

Ngaphezu kwalokho, amandla e-AC/DC athuthukisa ukusebenza kahle nokukhiqiza komshiseli. Ngokusebenzisa uhlobo olufanele lwamanje lwezinto ezishiselwe, opharetha bangakwazi ukuzuza ukushisela kwekhwalithi ephezulu ngokukhubazeka okumbalwa. Lokhu kunciphisa isidingo sokuphinda kusetshenzwe futhi kwandise ukukhiqiza jikelele. Ukwengeza, amandla okushintsha phakathi kwamamodi e-AC ne-DC alula futhi kalula inqubo yokushisela, konga isikhathi nomzamo.

Umjikelezo Womsebenzi kanye Nomthelela Wawo Ekukhiqizeni

Umjikelezo womsebenzi womshiseli we-TIG uyisici esibalulekile esithinta ngokuqondile ukukhiqiza. Umjikelezo wemisebenzi ubhekisela esikhathini umshiseli angasebenza ngaso ngokuqhubekayo ngesilinganiso esithile ngaphambi kokudinga ukupholisa. Isibonelo, umshiseli onomjikelezo womsebenzi ongu-60% kuma-amps angu-200 angashisela ngokuqhubekayo imizuzu engu-6 esikhathini esiyimizuzu eyi-10 ngaphambi kokudinga ukupholisa phansi kwemizuzu emi-4. Umjikelezo womsebenzi ophezulu uvumela izikhathi ezinde zokushisela, ukwandisa ukusebenza kahle nokunciphisa isikhathi sokuphumula.

Kuzicelo zezimboni, lapho amaphrojekthi amakhulu okushisela avamile, umjikelezo wemisebenzi ephezulu ubalulekile ekugcineni ukukhiqiza. Abashiseli abanomjikelezo womsebenzi ophezulu bangakwazi ukusingatha imisebenzi ebanzi futhi enzima ngaphandle kokuphazamiseka okuvamile. Lokhu kubaluleke kakhulu emikhakheni efana neyokwakha kanye neyokukhiqiza, lapho ukushisela okungapheli kuvame ukudingeka ukuze kuhlangatshezwane nezinsuku eziwumnqamulajuqu zephrojekthi nokugcina amashejuli okukhiqiza.

Ukwengeza, umjikelezo wemisebenzi uthinta ukusebenza okuphelele kwe-welder nokuphila isikhathi eside. Ukusebenzisa i-welder ngaphezu komjikelezo wayo womsebenzi kungaholela ekushiseni ngokweqile kanye nokulimala okungenzeka emishini. Ngakho-ke, ukukhetha i-welder enomjikelezo womsebenzi ofanele wezinhlelo zokusebenza ezihlosiwe kuqinisekisa ukusebenza okuthembekile futhi kwandisa isikhathi sokuphila semishini. Lokhu kucatshangelwa kubalulekile kumabhizinisi afuna ukukhulisa inzuzo yawo ekutshalweni kwezimali futhi anciphise izindleko zokuyilungisa.

Ukuphatheka Nesisindo

Ukuphatheka nesisindo yizici ezibalulekile okufanele uzicabangele lapho ukhetha i-TIG welder, ikakhulukazi izinhlelo zokusebenza ezidinga ukuhamba. Ama-welder angasindi futhi aphathekayo alungele umsebenzi wasendle, ukulungisa imisebenzi, namaphrojekthi abandakanya ukuhamba phakathi kwezindawo ezahlukahlukene. Lawa mashisela kulula ukuwathwala futhi awamise, okuwenza alungele imisebenzi yokushisela esizeni ezimbonini ezifana nezokwakha nokunakekela.

Isisindo se-welder siphinde sithinte ukusebenziseka kwayo kanye ne-ergonomics. Ama-welder alula kulula ukuphatha nokuqondisa, ukunciphisa ukukhathala komsebenzisi nokuthuthukisa ukusebenza kahle okuphelele. Lokhu kunenzuzo ikakhulukazi emisebenzini edinga ukushiselwa isikhathi eside noma ukusebenza ezindaweni ezivalekile. Ukwengeza, ama-welder aphathekayo avame ukuza nezici ezifana nezibambo zokuthwala noma amasondo, okuthuthukisa kakhulu ukuhamba kwawo kanye nokusebenziseka kalula.

Nokho, kubalulekile ukulinganisa ukuphatheka nokusebenza. Nakuba ama-welders alula elula, kufanele anikeze amandla anele nokusebenza kwezinhlelo ezihlosiwe. Ukuqinisekisa ukuthi i-welder ihlangabezana nezicaciso ezidingekayo zokuphuma kwamandla, umjikelezo wemisebenzi, nezinye izici zokusebenza kubalulekile ukuze kuzuzwe ukushiselwa kwekhwalithi ephezulu nokugcina ukukhiqiza. Ngakho-ke, amabhizinisi kufanele ahlole ngokucophelela izidingo zawo ezithile futhi akhethe i-welder enikeza inhlanganisela efanele yokuphatheka nokusebenza.

Lawula izici kanye nesixhumi esibonakalayo somsebenzisi

Izici zokulawula nokusebenzelana komsebenzisi kwe-TIG welder kuthinta kakhulu ukusebenziseka kwayo nokunemba kwayo. Izici zokulawula ezithuthukisiwe, ezifana ne-pulse welding, zivumela opharetha ukuthi balawule okokufaka ukushisa futhi banciphise ubungozi bokungqubuzana noma ukusha ngezinto ezincane. Lokhu kuwusizo ikakhulukazi ezinhlelweni ezidinga ukunemba okuphezulu, njenge-aerospace kanye nokukhiqizwa kwemishini yezokwelapha. Ukwengeza, izici ezifana nokugeleza kwangaphambi kokugeleza kanye nokulawula igesi yangemva kokugeleza zisiza ukuvikela indawo yokushisela ekungcoleni, iqinisekisa ukushisela kwekhwalithi ephezulu.

Isixhumi esibonakalayo esisebenziseka kalula sithuthukisa ikhono lomsebenzisi lokulungisa izilungiselelo ngokushesha nangokunembile. Izibonisi zedijithali nezilawuli ezinembile zikwenza kube lula ukusetha nokuqapha amapharamitha afana ne-amperage, i-voltage, nokugeleza kwegesi. Lokhu kunciphisa ijika lokufunda ku-opharetha abasha futhi kwandisa ukusebenza kahle kukonke. Ezilungiselelweni zezimboni, lapho ama-welders amaningi angasetshenziswa khona, isikhombimsebenzisi esingaguquki futhi esisebenziseka kalula siqinisekisa ukuthi bonke opharetha bangakwazi ukufeza imiphumela oyifunayo ngokuqeqeshwa okuncane.

Ngaphezu kwalokho, izilungiselelo ezihlelekayo nemisebenzi yenkumbulo ivumela opharetha ukuthi balondoloze futhi bakhumbule imingcele ethile yokushisela yezinhlelo zokusebenza ezahlukene. Lesi sici sizuzisa kakhulu ezindaweni zokukhiqiza lapho ukuhambisana nokuphindaphinda kubalulekile. Ngokugcina izilungiselelo ezithandwayo, opharetha bangashintsha ngokushesha phakathi kwemisebenzi ehlukene yokushisela ngaphandle kwesidingo sokulungiswa kwesandla, ukonga isikhathi nokunciphisa ingozi yamaphutha. Sekukonke, izici zokulawula ezithuthukisiwe kanye nesixhumi esibonakalayo esisebenziseka kalula kunomthelela ekuthuthukisweni kwekhwalithi yokushisela, ukusebenza kahle, nokwaneliseka komsebenzisi.

Izici zokuphepha kanye namazinga okuthobela

Izici zokuphepha nezindinganiso zokuthobela kubaluleke kakhulu lapho ukhetha i-TIG welder, njengoba ziqinisekisa ukuvikelwa kwabaqhubi nokuhambisana nemithetho yemboni. Izici eziyinhloko zokuphepha zihlanganisa ukuvikela ukugcwala okushisayo okushisayo, okuvimbela i-welder ekushiseni ngokweqile futhi kunciphisa ingozi yokulimala kwemishini kanye nokulimala komsebenzisi. Ukwengeza, izici ezifana nokuqalisa kwemvamisa ephezulu nokuzinza kwe-arc zisiza ukunciphisa ubungozi beziteleka ze-arc zengozi futhi zithuthukise ukuphepha kukonke phakathi nokusebenza.

Ukuthobelana namazinga embonini nezitifiketi, ezifana ne-CE, UL, ne-ISO, kubalulekile ukuze kuqinisekiswe ukuthi umashiseli uhlangabezana nezidingo zokuphepha nokusebenza. Lawa mazinga ahlinzeka ngesiqiniseko sokuthi okokusebenza kuhloliwe futhi kwaqinisekiswa ukusebenza okuphephile ngaphansi kwezimo ezihlukahlukene. Ezimbonini ezifana nezokwakha nezokukhiqiza, lapho imithetho yokuphepha iqinile, ukusebenzisa okokusebenza okuqinisekisiwe kubalulekile ekugcineni ukuthobela nokugwema imiphumela engase ibe khona yezomthetho neyezimali.

Ngaphezu kwalokho, izinto zokuzivikela (i-PPE) kanye nezinsiza zokuphepha, njengezigqoko zokushisela, amagilavu, nezingubo zokuzivikela, kufanele zisetshenziswe ngokuhambisana nomshiseli ukuze kuthuthukiswe ukuphepha komsebenzisi. Ukuqinisekisa ukuthi i-welder iyahambisana nalezi zinsiza futhi inikeza isivikelo esanele ezingozini ezinjengemisebe ye-UV, izinhlansi, nentuthu kubalulekile ekudaleni indawo yokusebenza ephephile. Ngokubeka kuqala izici zokuphepha nezindinganiso zokuthobela, amabhizinisi angavikela abasebenzi bawo, anciphise ubungozi bezingozi, futhi agcine indawo yokusebenza ephephile nekhiqizayo.

Izinhlobo ze-TIG Welders kanye nezicelo zazo

Izishicileli ze-TIG ezisekelwe ku-Inverter

Amashisela e-TIG asekelwe ku-inverter aziwa ngokusebenza kahle kwawo nokuguquguquka. Lawa mashisela asebenzisa izingxenye ze-elekthronikhi ezithuthukisiwe ukuze aguqule amandla ngendlela ephumelela kakhudlwana, okuholela ekwakhiweni okuhlangene nokungasindi. Lokhu kuzenza zilungele izinhlelo zokusebenza ezidinga ukuphatheka, njengomsebenzi wasendle kanye nokulungiswa kwendawo. Ukwengeza, ama-welder asekelwe ku-inverter ahlinzeka ngokulawula okunembile phezu kwemingcele yokushisela, okuvumela ukushisela kwekhwalithi ephezulu ezintweni ezihlukahlukene, okuhlanganisa i-aluminium, insimbi engagqwali, ne-titanium.

Ubuchwepheshe obuthuthukisiwe obusetshenziswa kuma-welder asekelwe ku-inverter buhlinzeka ngezinzuzo ezimbalwa, kufaka phakathi umjikelezo womsebenzi ophezulu kanye nokuzinza kwe-arc okuthuthukisiwe. Lokhu kuvumela izikhathi ezinde zokushisela nokusebenza okungaguquguquki, okuzenza zifanelekele izinhlelo zokusebenza zezimboni lapho ukukhiqiza nokuthembeka kubaluleke kakhulu. Emikhakheni efana ne-aerospace kanye nezimoto, lapho ukunemba kanye nekhwalithi kubaluleke kakhulu, ama-welder e-TIG asekelwe ku-inverter akhethwa ngenxa yekhono lawo lokukhiqiza ama-welds ahlanzekile nangenasici.

Ngaphezu kwalokho, ama-welders asekelwe ku-inverter angonga amandla, anciphisa ukusetshenziswa kwamandla nezindleko zokusebenza. Lokhu kunenzuzo ikakhulukazi emisebenzini emikhulu yokukhiqiza lapho ukonga amandla kungase kube nomthelela omkhulu kumugqa obalulekile. Amandla okusebenza emithonjeni yamandla ehlukene, okuhlanganisa namajeneretha, athuthukisa nakakhulu ukuguquguquka kwawo futhi ayenze ifanelekele ukusetshenziswa ezindaweni ezikude. Sekukonke, amashisela e-TIG asuselwa ku-inverter anikezela ngenhlanganisela yokuphatheka, ukunemba, nokusebenza kahle, okuwenza abe yimpahla ebalulekile ezimbonini ezahlukahlukene.

Izishicileli ze-TIG ezisekelwe ku-Transformer

Abashiseli be-TIG abasuselwa ku-Transformer baziwa ngokuhlala kwabo nokuqina. Lawa mashisela asebenzisa ubuchwepheshe be-transformer bendabuko ukuguqula amandla, okuholela ekwakhiweni okukhudlwana futhi esindayo uma kuqhathaniswa nama-welder asekelwe ku-inverter. Kodwa-ke, ubulula nokuthembeka kwazo kuzenza zilungele izinhlelo zokusebenza ezisindayo kanye nezindawo lapho ubumangelengele bubalulekile. Izimboni ezifana nokwakha imikhumbi, ukwakha, kanye nokukhiqiza okusindayo kuvame ukukhetha amashisela asuselwa ku-transformer ukuze akwazi ukuphatha imisebenzi enzima.

Enye yezinzuzo ezibalulekile zamashisela asekelwe ku-transformer yikhono labo lokuletha ukusebenza okungaguquki ngaphansi kwezimo eziyinselele. Azizwela kakhulu ekuguquguqukeni kwamandla futhi zingasebenza kahle ezindaweni ezinempahla yamandla engazinzile. Lokhu kuwenza afanelekele ukusetshenziswa ezindaweni ezikude kanye nezilungiselelo zezimboni lapho ikhwalithi yamandla ingaba yinkinga. Ukwengeza, ukwakhiwa kwazo okuqinile kuqinisekisa ukwethembeka kwesikhathi eside futhi kunciphisa isidingo sokunakekelwa nokulungiswa njalo.

Nakuba ama-welder asekelwe ku-transformer angase antule ezinye zezici ezithuthukisiwe zamamodeli asekelwe ku-inverter, anikeza inani elihle kakhulu lezinhlelo zokusebenza ezidinga ukuphuma kwamandla aphezulu nokuqina. Ikhono labo lokuphatha izinto eziwugqinsi futhi linikeze ukungena okujulile lizenza zilungele ukushisela izingxenye zesakhiwo nemishini esindayo. Ngokukhetha i-welder-based TIG welder, amabhizinisi angazuza ekusebenzeni okuthembekile nokuphila isikhathi eside, ukuqinisekisa ukuthi izidingo zabo zokushisela ziyahlangatshezwa ngisho nasezindaweni ezinzima kakhulu.

Multi-Process Welders

Abashiseli bezinqubo eziningi banikeza ukuguquguquka kokwenza amasu okushisela ahlukahlukene, okuhlanganisa i-TIG, i-MIG, kanye nokushisela induku. Lokhu kuvumelana nezimo kubenza babe ukukhetha okuhle kakhulu kumabhizinisi adinga izinqubo ezahlukene zokushisela zezinhlelo zokusebenza ezahlukahlukene. Ama-welders ezinqubo eziningi anenzuzo ikakhulukazi ezimbonini ezifana nokukhanda izimoto, ukwakhiwa, nokugcinwa, lapho imisebenzi yokushisela ehlukene ingase idingeke kuphrojekthi eyodwa. Amandla okushintsha phakathi kwezinqubo ngokushesha futhi kalula athuthukisa ukukhiqiza futhi anciphise isidingo semishini eminingi.

Ukuhlanganiswa kwezinqubo eziningi zokushisela emshinini owodwa nakho kunikeza ukonga izindleko nokusebenza kahle kwesikhala. Esikhundleni sokutshala imali kuma-welders ahlukene ngenqubo ngayinye, amabhizinisi angasebenzisa i-welder enezinqubo eziningi ukuphatha imisebenzi eminingi. Lokhu kunciphisa ukutshalwa kwezimali kokuqala kanye nezindleko zokunakekela okuqhubekayo, okwenza kube yisixazululo esingabizi kakhulu emabhizinisini amancane naphakathi nendawo. Ukwengeza, umklamo ohlangene wama-welder wezinqubo eziningi wonga indawo yokusebenzela ebalulekile, enenzuzo ikakhulukazi kuma-workshops nasezikhungweni zokukhiqiza ezinendawo elinganiselwe.

Ngaphezu kwalokho, ama-welder ezinqubo eziningi avame ukuza nezici ezithuthukile nezilawuli zedijithali ezithuthukisa ukusebenziseka nokusebenza kwazo. Izici ezifana nokulungiswa kwepharamitha okuzenzakalelayo, izilungiselelo zenkumbulo, nokuxhumana okunembile kwenza kube lula ku-opharetha ukuzuza ukushisela okungaguquki nokusezingeni eliphezulu. Lokhu kubaluleke kakhulu ezindaweni zokukhiqiza lapho ukusebenza kahle nokunemba kubalulekile. Ngokutshala imali kumshini wokushisela onezinqubo eziningi, amabhizinisi angazuza ekusebenziseni izinto ezihlukahlukene, ukonga izindleko, namakhono athuthukile anikezwa yile mishini.

Amathrendi asafufusa ku-TIG Welding Technology

I-Automation kanye ne-Robotics Integration

Ukuhlanganiswa kwe-automation kanye namarobhothi ku-TIG welding kuwumkhuba obalulekile obumba ikusasa lemboni. Izinhlelo zokushisela ezizenzakalelayo kanye nama-robotic welders zinikeza ukunemba okwengeziwe, ukungaguquguquki, nokusebenza kahle, okuzenza zilungele izindawo zokukhiqiza ivolumu ephezulu. Lezi zinhlelo zingenza imisebenzi yokushisela eyinkimbinkimbi ngokungenelela okuncane komuntu, ukunciphisa ubungozi bamaphutha kanye nokwenza ngcono umkhiqizo jikelele. Ezimbonini ezinjengezezimoto kanye ne-aerospace, lapho ukunemba nokuphindaphinda kubalulekile, ukwamukelwa kwezinhlelo zokushisela ezizenzakalelayo ze-TIG kuyanda.

Amasistimu wokushisela amarobhothi nawo athuthukisa ukuphepha ngokunciphisa isidingo sokuba opharetha basebenze ezindaweni eziyingozi. Ngokwenza imisebenzi ephindaphindwayo neyingozi, amabhizinisi angavikela abasebenzi bawo futhi athobele imithetho eqinile yokuphepha. Ukwengeza, ukusetshenziswa kwamarobhothi ekushiseleni kuvumela ukuguquguquka okukhulu ezinqubweni zokukhiqiza, okwenza abakhiqizi bakwazi ukuzivumelanisa ngokushesha nezimfuno eziguqukayo nezimo zemakethe. Lo mkhuba kulindeleke ukuthi uqhubeke njengoba intuthuko kwezobuchwepheshe berobhothi kanye ne-automation iqhuba ukuthuthuka ekusebenzeni kahle kwe-welding kanye nekhwalithi.

Ukuthuthuka Kwezinto Zokushisela Nezinto Ezisetshenziswayo

Ukuthuthuka kwezinto zokushisela nezinto ezisetshenziswayo kuqhuba ukuthuthukiswa kokusebenza kwe-TIG kokushisela nokusebenza kahle. Ukuthuthukiswa kwezinto ezintsha zokugcwalisa kanye nama-electrode anezici ezithuthukisiwe, njengamandla akhulayo nokumelana nokugqwala, kuvumela ikhwalithi engcono ye-weld nokuqina. Le ntuthuko ibaluleke kakhulu ezimbonini ezifana nowoyela negesi, lapho izinto zokushisela zichayeka endaweni enzima futhi kufanele zimelane nezimo ezimbi kakhulu. Ukusetshenziswa kwezinto ezithuthukisiwe kuqinisekisa ukuthi ama-welds agcina ubuqotho nokusebenza kwawo ngokuhamba kwesikhathi.

Ukuqanjwa kwezinto ezisetshenziswayo, okufana namagesi avikelayo athuthukisiwe nokuguquguquka, nakho kunomthelela kwikhwalithi engcono yokushisela nokusebenza kahle. Lezi zinto ezisetshenziswayo zisiza ukuvikela indawo yokushisela ekungcoleni futhi ithuthukise ukuqina kwe-arc, okuholela ekushiseleni okuhlanzekile nokunamandla. Ukwengeza, ukuthuthukiswa kwezinto ezisetshenziswayo zokushisela ezinobungani bemvelo neziqhubekayo kuhambisana nokugcizelela okukhulayo kwesibopho sezemvelo ekukhiqizeni. Ngokwamukela izinto ezithuthukisiwe nezinto ezisetshenziswayo, amabhizinisi angafinyelela izinga eliphezulu lokushisela, anciphise imfucuza, futhi athuthukise imizamo yawo yokusimama.

Amasistimu Okunemba Nokulawula Okuthuthukisiwe

Ukunemba okuthuthukisiwe kanye nezinhlelo zokulawula zishintsha ubuchwepheshe bokushisela be-TIG, okwenza opharetha bafinyelele amazinga aphezulu okunemba nokungaguquguquki. Amasistimu okulawula athuthukile, afana nokusebenzelana kwedijithali nezilungiselelo ezihlelekayo, avumela ukulungiswa okunembile kwamapharamitha wokushisela, okuqinisekisa ukusebenza okuphelele kwezinto ezisetshenziswayo nezinhlelo zokusebenza. Lawa masistimu ahlinzeka ngempendulo yesikhathi sangempela kanye nokuqapha, okusiza opharetha ukuthi bagcine ikhwalithi yokushisela engaguquki futhi banciphise ubungozi bokulimala. Ezimbonini ezifana nokukhiqizwa kwemishini yezokwelapha, lapho ukunemba kubalulekile, lezi ntuthuko zibaluleke kakhulu.

Ukuhlanganiswa kobuchwepheshe obukhaliphile, obufana nobuhlakani bokwenziwa nokufunda ngomshini, kuthuthukisa ngokwengeziwe amandla ezinhlelo zokushisela ze-TIG. Lobu buchwepheshe buvumela abashiseli ukuthi bafunde kuma-welds angaphambilini futhi balungiselele amapharamitha ngokuzenzakalelayo, bathuthukise ukusebenza kahle futhi banciphise isidingo sokulungiswa ngesandla. Ukwengeza, ukusetshenziswa kwezinzwa nokuhlaziywa kwedatha kuvumela ukugcinwa okubikezelwayo kanye nokuqapha ngesikhathi sangempela semishini yokushisela, ukuqinisekisa ukuthi izinkinga ezingase zibe khona ziyabonakala futhi zixazululwe ngaphambi kokuba zibe nomthelela ekukhiqizeni. Ngokusebenzisa amasistimu wokunemba nokulawula okuthuthukisiwe, amabhizinisi angafinyelela izinga eliphezulu lokushisela, andise umkhiqizo, futhi ehlise izindleko zokusebenza.

Ukuhlola Izindleko Eziphelele Zobunikazi Zabashiseli be-TIG

Izindleko Zokuthenga Zokuqala

Izindleko zokuthenga zokuqala ze-TIG welder ziyisici esibalulekile okufanele icatshangelwe lapho kuhlolwa inani lezindleko zobunikazi. Lezi zindleko zihlanganisa intengo ye-welder ngokwayo, kanye nanoma yiziphi izesekeli ezengeziwe kanye nemishini edingekayo ukuze usebenze. Amashisela ekhwalithi ephezulu e-TIG anezici ezithuthukile namandla angase abe nezindleko eziphezulu, kodwa ngokuvamile ahlinzeka ngokusebenza okungcono nokuqina. Ukutshala imali kumshini wokushisela onokwethenjelwa futhi ophumelelayo kungaholela ekongeni isikhathi eside ngokunciphisa isidingo sokulungiswa njalo nokushintshwa.

Lapho uhlola izindleko zokuthenga zokuqala, kubalulekile ukucabangela izidingo ezithile kanye nezidingo zezinhlelo zokusebenza ezihlosiwe. Isibonelo, i-welder enomjikelezo womsebenzi ophezulu kanye nokuphuma kwamandla kungase kudingeke ezinhlelweni zemboni, kuyilapho imodeli eyisisekelo ingase yanele imisebenzi elula. Ukwengeza, izindleko zezinto ezisetshenziswayo, njengama-electrode namagesi okuvikela, kufanele zifakwe kusabelomali sonke. Ngokuhlola ngokucophelela izindleko zokuthenga zokuqala nokukhetha i-welder ehlangabezana nezicaciso ezidingekayo, amabhizinisi angaqinisekisa ukutshalwa kwezimali okungabizi kakhulu.

Izindleko Zokusebenza Nokunakekela

Izindleko zokusebenza nezokulungisa ziyizindleko eziqhubekayo ezifaka isandla esipheleleni sezindleko zobunikazi bomshini wokushisela we-TIG. Lezi zindleko zihlanganisa ukusetshenziswa kukagesi, izinto ezisetshenziswayo, kanye nokugcinwa nokulungiswa okujwayelekile. Ama-welders awonga amandla anezici zokuphatha amandla ezithuthukisiwe angasiza ekunciphiseni izindleko zikagesi, awenze abe yinketho eyongayo yokusebenzisa isikhathi eside. Ukwengeza, ukutholakala nezindleko zezinto ezisetshenziswayo, njengezinto zokugcwalisa namagesi okuvikela, kufanele kubhekwe lapho kuhlolwa izindleko zokusebenza.

Ukugcinwa okuvamile kubalulekile ukuze kuqinisekiswe ukuphila isikhathi eside nokusebenza komshiseli we-TIG. Lokhu kuhlanganisa ukuhlolwa okujwayelekile, ukuhlanzwa, nokushintshwa kwezingxenye ezigugile. Izindleko zokunakekelwa zingahluka kuye ngokuthi yinkimbinkimbi nokuqina kwe-welder. Ama-welders anokwakhiwa okuqinile kanye nezingxenye zekhwalithi ephezulu angase adinge ukulungiswa okungavamile, okuholela ezindleko eziphansi eziphelele. Ukwengeza, ukutholakala kwezingxenye ezisele kanye nokwesekwa komkhiqizi kungaba nomthelela ezindlekweni zokulungisa. Ngokukhetha i-welder enezindleko eziphansi zokusebenza nezokulungisa, amabhizinisi anganciphisa isikhathi sokuphumula futhi andise umkhiqizo.

Ukusebenza kahle kwamandla kanye nokonga kwesikhathi eside

Ukusebenza kahle kwamandla kuyisici esibalulekile ekuhloleni izindleko eziphelele zobunikazi bomshini wokushisela we-TIG. Ama-welder awonga amandla adla amandla amancane, okuholela emalini ephansi kagesi kanye nomthelela ongemuhle kwezemvelo. Ama-welder asekelwe ku-inverter, isibonelo, aziwa ngokusebenza kahle kwamandla aphezulu futhi anganikeza ukonga okuphawulekayo kwesikhathi eside uma kuqhathaniswa namamodeli asekelwe ku-transformer yendabuko. Ukwengeza, abashiseli abonga amandla bavame ukuba nomjikelezo wemisebenzi ephakeme, okuvumela isikhathi eside sokushisela kanye nokukhiqiza okukhulayo.

Ukonga isikhathi eside kungafinyelelwa ngokusebenzisa izici ezithuthukisiwe nobuchwepheshe obuthuthukisa ukusebenza nokunciphisa ukumosha. Isibonelo, abashiseli abanezilungiselelo ezihlelekayo nezilawuli zedijithali bangathuthukisa amapharamitha wokushisela wezinhlelo zokusebenza ezihlukene, okuholela ekushiseleni kwekhwalithi ephezulu nokuncipha kokusebenza kabusha. Ukusetshenziswa kwezinto ezisebenzisekayo ne-eco-friendly kanye nezinto zokwakha kungafaka isandla nakakhulu ekongeni izindleko.

Ukuhlanganisa

Abashiseli be-TIG babalulekile kuzo zonke izimboni ezidinga ukunemba nekhwalithi. Ngesidingo esikhulayo somhlaba wonke, izinto ezifana nokuphuma kwamandla, amandla e-AC/DC, nezici zokuphepha zibalulekile ekukhetheni isishiseli esifanele. Ukwakhiwa kwezinto ezishintshayo kanye nezinto zokwakha kuthuthukisa ukusebenza, ukusebenza kahle, nokonga izindleko, okwenza amawelder e-TIG abe utshalomali oluhlakaniphile lwamabhizinisi ahlose ukushisela okusezingeni eliphezulu, okukhiqizayo.