Uma usebhizinisini lokulondoloza nokuvikela amadokhumenti, uyazi ukuthi isikhwama se-laminator singaba umngane wakho omkhulu. Njengosomabhizinisi, uthisha, noma umuntu othanda umsebenzi wokuzilibazisa okhiqiza amakhadi ebhizinisi, omazisi, izimemo, amadecal, izitifiketi, nanoma yimuphi omunye umbhalo, ama-laminator kanye nezikhwama ze-laminator zidlala indima ebalulekile. Kulabo abangazi, izikhwama ze-laminator zingamashidi epulasitiki elayiniwe ngaphambilini noma amashidi epulasitiki asetshenziselwa ukuhlanganisa idokhumenti ukuze kukhishwe. Kulo mhlahlandlela, sizohlinzeka ngokuhlolwa okujulile kwezingxenye ezibalulekile zezikhwama ze-laminator. Uzofunda okuningi ngaleli thuluzi elibonakala lithobekile futhi nakanjani uzohlomela kangcono ukwenza izinqumo ngohlobo lwezikhwama ze-laminator okufanele uzisebenzise.

Okuqukethwe:

1. Ukuqonda izinhlobo zesikhwama se-laminator

2. Ukukhetha ubukhulu besikhwama esifanele

3. Osayizi abajwayelekile nabangokwezifiso

4. Ukusebenzisa izikhwama ze-laminator ngendlela efanele

5. Ukuxazulula izinkinga ezivamile

Ukuqonda izinhlobo zesikhwama se-laminator

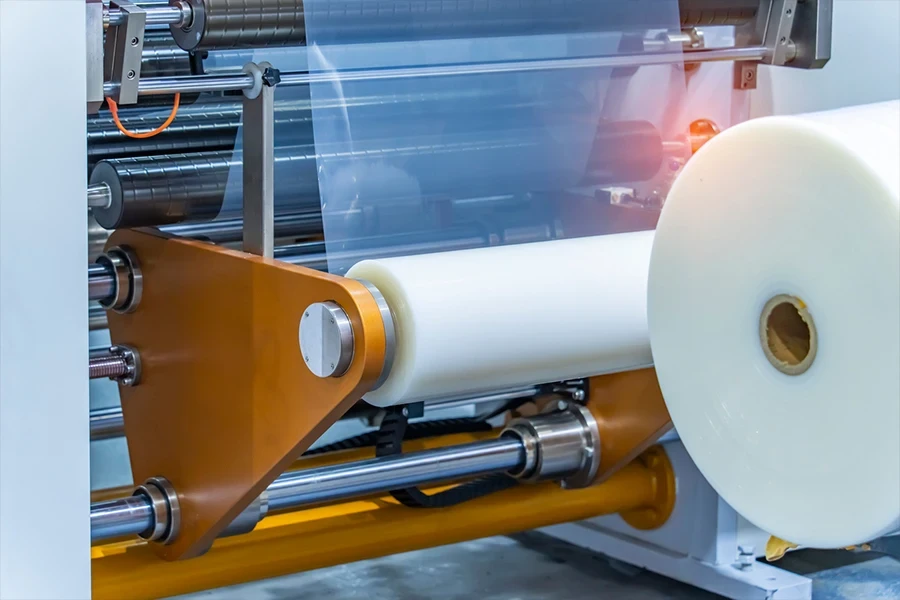

Izikhwama ze-laminator ziza ngezinhlobo ezahlukene, eziklanyelwe ukuhlangabezana nezidingo ezahlukene. Izinhlobo ezivame kakhulu yizikhwama ezishisayo nezibandayo. Izikhwama ezishisayo zidinga ukushiselwa ukuze zivale, futhi zisetshenziselwa kakhulu imibhalo yasehhovisi, amaflaya, izincwajana, izincwajana namakhava ezincwadi, amaphosta, amabhanela, amamenyu, ukukhangisa kwamafasitela esitolo, amabhodi ezikhangiso aseceleni komgwaqo, izincwadi zokufunda nezinto zokufunda. Izikhwama ezibandayo zibizwa nangokuthi i-adhesive sensitive sensitive, efanelekile kumadokhumenti angezwani nokushisa nezithombe.

Esinye isikhwama se-self-laminating. Lolu hlobo aludingi umshini wokukhipha i-laminating futhi, ngakho-ke, lulungele noma yiziphi izinjongo ezisheshayo futhi ezihamba phambili. Ukuqonda izinhlobo ezahlukene kubaluleke kakhulu ngaphambi kokukhetha isikhwama esifanele sephrojekthi yakho.

Uhlobo lwesikhwama sokumboza kwesokudla lwenza ukuphepha kwamadokhumenti akho kanye nokuthuthukiswa kokubukeka kwawo. Cabanga ngohlobo lokusetshenziswa okungokoqobo onakho entweni enamayini bese ukhetha isikhwama se-laminator esifanele. Ukuqina nokucaca nakho kubalulekile.

Ukukhetha ubukhulu besikhwama esifanele

Ukuqina kuwukucatshangelwa okubalulekile ekusebenzeni kwezikhwama ze-laminator. Ugqinsi lwezikhwama lulinganiswa ngama-mils (izinkulungwane zeyintshi), futhi ngokuvamile lusebangeni elingu-3 mil ukuya ku-10 mil. Isikhwama esiwugqinsi sinikeza ukusekela okuqinile futhi singcono kumkhiqizo ophathwa kakhulu, njengamakhadi omazisi nezinto zokufundisa.

Ukuze uthole izitifiketi noma imibiko, izikhwama ze-3 ukuya ku-5 mil zinikeza ukuguquguquka okuhle, kanye nenani elihle lokuvikela. Uma, nokho, uphrinta amamenyu noma izimpawu zebhizinisi, ungase ufise ukuthuthukela kuzikhwama ezingu-7 kuya kwezingu-10 mil.

Inani lesibili okufanele ulicabangele ukujiya. Izikhwanyana eziwugqinsi kakhulu zingenza amadokhumenti akho aqine futhi abe ntekenteke, kuyilapho izikhwama ezizacile zizovumela umphumela ukuthi uhlale uvumelana nezimo futhi kulula ukuwuphatha. Kuzodingeka ukhethe ukujiya okufanelana kangcono nokusetshenziswa okuhlosiwe kwamadokhumenti akho ane-laminated.

Osayizi abajwayelekile nabangokwezifiso

Izikhwama ze-laminator zitholakala ngebanga lamasayizi ajwayelekile. Osayizi abadingeka kakhulu bangabobukhulu bamadokhumenti asetshenziswa kakhulu. Lokhu kufaka uhlamvu (8.5 x 11 amayintshi), olusemthethweni (8.5 x 14 amayintshi) nosayizi bekhadi lebhizinisi (2 x 3.5 amayintshi) osayizi. Uma unesidingo sokukodwa kwalokhu, maningi amathuba okuthi isikhwama se-laminator esisebenzisekayo sesivele sitholakalela ukusetshenziswa kwakho.

Kodwa-ke kukhona osayizi bangokwezifiso, amaroli ahlukile adinga izikhwama ezihlukile, amaphrojekthi akhethekile angase agunyaze osayizi bephepha bangokwezifiso noma imibhalo ekhethekile edinga ukupakishwa. Esinye isibonelo esihle amaphosta amakhulu. Izikhathi eziningi, zingagoqwa esikhwameni sosayizi ojwayelekile. Kodwa-ke, ukuze uqinisekise ubuqotho obugoqiwe futhi uvimbele ukuklama, izikhwama ezinosayizi wangokwezifiso ziyadingeka ngezinye izikhathi. Amaroli amakhulu amakhulu ento emise okwenqaba, njenge-turntable ekhethekile, angase asho isidingo sosayizi wangokwezifiso.

Lapho wenza ukukhetha phakathi kosayizi abajwayelekile nabangokwezifiso, kubaluleke kakhulu ukuhlaziya uhlobo lwamadokhumenti ohlose ukuwenza laminate kanye nenjongo yakho yokwenza i-lamination. Nakuba osayizi abajwayelekile kuyibo osayizi abadume kakhulu nabangabizi kakhulu amakhasimende avame ukuya kubo, osayizi bangokwezifiso bangosayizi abaklanywe ngokukhethekile abafanelana nezidingo zakho ezihlukile, ukuze kuqinisekiswe ukuthi idokhumenti yakho iyilokho okufanele ibe yikho.

Ukusebenzisa izikhwama ze-laminator ngendlela efanele

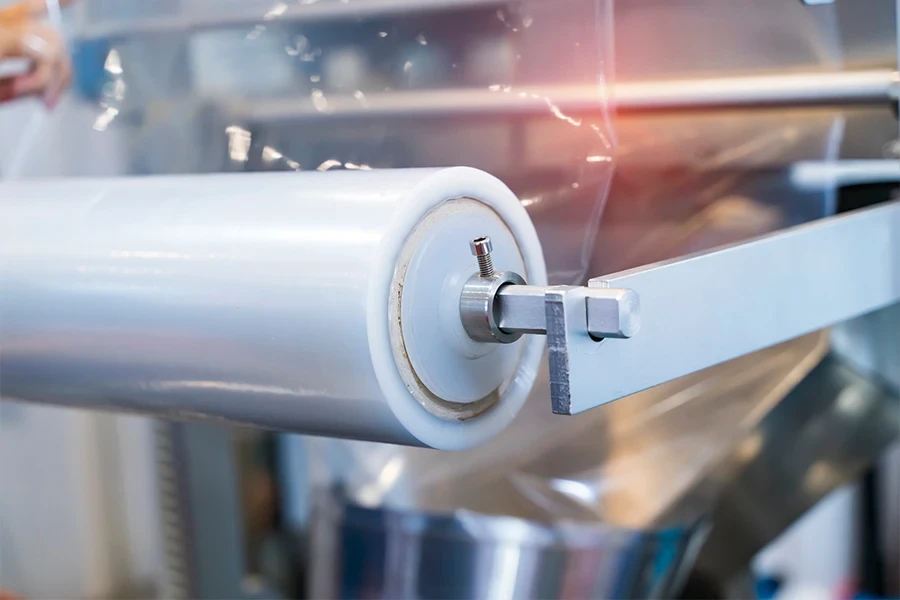

Ukusetshenziswa okungalungile kungathinta kakhulu ikhwalithi yomphumela wokugcina, ngakho-ke kufanele unake ngokukhethekile izikhwama ze-laminator. Qala ngokukhethwa kohlobo nosayizi wezikhwama zedokhumenti yakho - kufanele ibe nosayizi olungile. Uma kunezikhwama ezishisayo, hlola ukuthi i-laminator ishisa kuze kufike ezingeni elifanele. Faka idokhumenti ngaphakathi kwesikhwama futhi uqiniseke ukuthi iqondaniswe kahle – ngaphandle kwalokho ingase ibekwe endaweni engafanele noma ithole amabhamuza.

Ngaso sonke isikhathi faka isikhwama ku-laminator ngonqenqema oluvalekile kuqala - lokhu kugwema ukuminyana futhi kuqinisekisa ukulanyiswa okungaguquki. Cindezela phansi ngokuqinile ohlangothini olulodwa ukuze uthole izikhwama ezibandayo, kusukela ngemuva kweyunithi ukuya phambili, wenze okunamathelayo kusebenze njengoba uya, futhi ulungise noma imaphi amabhamuza omoya.

Ukuyisebenzisa ngendlela efanele kusho nokugcina i-laminator yakho ngokuqinisekisa ukuthi uwahlanza njalo ama-roller ukuze angabi ne-adhesive buildup, futhi azohamba kahle.

Ukuxazulula izinkinga ezivamile

Ngisho nezindlela ezihamba phambili, ungase uhlangabezane nezinkinga. Amabhamuza omoya, isibonelo, angenzeka uma idokhumenti ingafakwanga ezikhwameni ngendlela efanele - kungaba ngenxa yengcindezi engalingani noma ngohlobo oluthile lwemfucumfucu noma izinsalela kumarola. Uma i-laminator yakho ikhipha amakhasi anamabhamuza, qiniseka ukuthi amadokhumenti angaphakathi ayisicaba futhi amarola ahlanzekile.

Enye inkinga ukuminyana kwezikhwama, ngokuvamile okubangelwa ukuphakela isikhwama ngokungafanele; qiniseka ukuthi ngaso sonke isikhathi uphakela unqenqema oluvaliwe kuqala nokuthi isikhwama siyisikwele ngaphambi kokuthi usifake ku-laminator; uma kwenzeka ujamu, akufanele wethuke; njengoba isikhwama sidla kusukela phansi, hlehlisa kancane amarola ukuze uhlehle isikhwama esine-laminated bese usifaka kabusha.

Okwesithathu, i-lamination engalingani ibangelwa ukusebenzisa izinga lokushisa elingalungile - bheka imanuwali efike ne-laminator yakho. Izokutshela izinga lokushisa elilungile ngokusekelwe kubukhulu besikhwama. Kushisa kakhulu noma kubanda kakhulu, futhi uzothola uphawu olungalingani, oluzokwenza ubuciko bakho be-laminated bubukeke bungenamsebenzi.

Isiphetho

Izikhwama zokufakelwa zithuthukisa futhi zivikele noma yiluphi uhlobo lwedokhumenti. Kungaba nzima ukuthola ukuthi ungasikhetha kanjani isikhwama esilungile sephrojekthi yakho, ukuthi ungakhetha kanjani ubukhulu obufanele, nokuthi ungakala kanjani usayizi. Udinga ukwazi ukuthi ungathola kanjani imiphumela engcono kakhulu kanye nendlela yokusebenzisa umshini, kanye nendlela yokuxazulula ezinye zezinkinga ezivame kakhulu. Nakho konke lokhu onakho, ungakwazi ngokuzethemba ukuthatha noma yimuphi umsebenzi laminating.