Ngo-2025, imakethe ye-acrylic laser cutter iyakhula, iqhutshwa intuthuko kubuchwepheshe be-laser kanye nezinhlelo zokusebenza ezahlukahlukene. Lesi sihloko sinikeza ukuhlaziywa okujulile kwemakethe, okugqamisa ukucatshangelwa okubalulekile kwabathengi abangochwepheshe. Inikeza imininingwane ebalulekile ekukhetheni umshini olungile, igcizelela ukubaluleka kokunemba, isivinini, nokusebenza kahle. Lo mhlahlandlela uklanyelwe ukusiza abathengi bebhizinisi ekwenzeni izinqumo ezinolwazi, ukuqinisekisa ukuthi bayagcina futhi badayise imikhiqizo esezingeni eliphezulu.

Okuqukethwe:

– Acrylic Laser Cutter Market Uhlolojikelele

- Isingeniso Esiningiliziwe Nokuhlaziywa Kwemakethe Ye-Acrylic Laser Cutter

- Izinto Ezibalulekile Lapho Ukhetha I-Acrylic Laser Cutter

- Ubuchwepheshe obuthuthukisiwe kuma-Acrylic Laser Cutters

- Ukusebenza kahle kwamandla kanye nokucatshangelwa kwemvelo

- Amazinga Okuphepha kanye Nezitifiketi

- Ukuhambisana nokuthuthukiswa kwekusasa

- Isifinyezo

I-Acrylic Laser Cutter Market Uhlolojikelele

Imakethe yomhlaba wonke ye-acrylic laser cutter ibhekene nokukhula okuphawulekayo, okuqhutshwa intuthuko kubuchwepheshe be-laser kanye nokwandisa izinhlelo zokusebenza kuzo zonke izimboni ezihlukahlukene. Ngo-2030, imakethe kulindeleke ukuthi ifinyelele ku-USD 10.22 billion, ikhula ngesilinganiso sokukhula esihlanganisiwe sonyaka (CAGR) esingu-4.94% sisuka ku-USD 7.29 billion ngo-2023. Lokhu kukhula kubangelwa kakhulu ukwanda kwesidingo sokunemba nokusebenza kahle kwezokukhiqiza, ikakhulukazi emikhakheni efana nezimoto, ugesi wabathengi, kanye nokukhiqizwa kwezimboni.

Ama-acrylic laser cutters asetshenziselwa ngokuyinhloko ukusika nokuqopha izinto ze-acrylic, ezisetshenziswa kakhulu kuzimpawu, izitendi zokubonisa, nezinto zokuhlobisa. Ukuhlukahluka kwale mishini, kuhlangene nekhono layo lokukhiqiza imiklamo yezinga eliphezulu, eyinkimbinkimbi, kuyenza ibaluleke kakhulu ekukhiqizeni kwesimanje. Imakethe ihlukaniswe ngobuchwepheshe, okuhlanganisa amalaser egesi, ama-lasemiconductor lasers, nama-solid state lasers, ama-fiber lasers athola ukudonseka okukhulu ngenxa yokusebenza kahle kwawo kanye nezindleko eziphansi zokusebenza.

Isifunda sase-Asia-Pacific sibusa imakethe ye-acrylic laser cutter, eqhutshwa ukuthuthuka kwezimboni ngokushesha, ukufudukela emadolobheni, kanye nentuthuko yezobuchwepheshe emazweni afana neChina, Japan kanye neNingizimu Korea. Lesi sifunda kulindeleke ukuthi sigcine isikhundla saso esihamba phambili, ngokutshalwa kwezimali okukhulu kwingqalasizinda yokukhiqiza kanye nokugcizelela okukhulayo kobunjiniyela obuzenzakalelayo nobunembayo. INyakatho Melika kanye ne-Europe nazo zinamasheya abalulekile ezimakethe, kanti i-United States neJalimane ibamba iqhaza elibalulekile ngenxa yemikhakha yazo yokukhiqiza eqinile kanye nokwamukelwa kobuchwepheshe obuthuthukile.

Isingeniso Esiningiliziwe Nokuhlaziywa Kwemakethe Ye-Acrylic Laser Cutter

Abasiki be-laser be-Acrylic baziswa kakhulu ngokunemba kwabo, isivinini, kanye nekhono lokusingatha imiklamo eyinkimbinkimbi, okuyenza ibaluleke kakhulu ezimbonini ezihlukahlukene. Izilinganiso zokusebenza ezibalulekile zale mishini zihlanganisa isivinini sokusika, ukunemba, kanye nekhono lokusika phakathi kogqinsi obuhlukene bezinto ze-acrylic. Imakethe ishintshela emithonjeni ye-laser esebenza kahle kakhulu futhi engabizi kakhulu, njengama-laser fibre, anikeza isivinini sokusika esiphezulu kanye nezidingo zokulungisa eziphansi uma kuqhathaniswa namalaser endabuko e-CO2.

Amandla esabelo semakethe athonywa indawo yokuncintisana, enabadlali abakhulu abafana ne-TRUMPF SE + Co. KG, i-Han's Laser Technology Industry Group Co., Ltd., kanye ne-Epilog Laser ehola imakethe. Lezi zinkampani zihlala zenza izinto ezintsha ukuze zithuthukise ukunikezwa kwemikhiqizo yazo futhi zigcine umkhawulo wokuncintisana. Ukuthuthuka kwezobuchwepheshe be-laser kuholele emishinini efinyelela ukunemba okuphezulu kanye nesivinini sokusika ngokushesha, ehlangabezana nesidingo esikhulayo semikhiqizo ye-acrylic ephezulu.

Imithelela yezomnotho, njengokuguquguquka kwamanani entengo yezinto ezingavuthiwe kanye nezinguquko ezindlekweni zokukhiqiza, kudlala indima ebalulekile ekulolongeni imakethe. Ukwengeza, amashifu okuziphatha kwabathengi, ikakhulukazi isidingo esikhulayo semikhiqizo eyenziwe ngokwezifiso nekhangayo ngobuhle, kuqhuba ukwamukelwa kwama-acrylic laser cutters. Iziteshi zokusabalalisa sezishintshile, nezinkundla eziku-inthanethi zithola ukuvelela njengeziteshi ezibalulekile zokuthengisa, ezinikeza ukufinyelela okulula kuhlu olubanzi lwemikhiqizo futhi zenze abakhiqizi bakwazi ukufinyelela isisekelo samakhasimende somhlaba wonke.

Izinqubo ezintsha zakamuva zihlanganisa ukudidiyelwa kwedijithali kanye ne-automation, ukuthuthukisa ukusebenza kahle kokukhiqiza kanye nokuguquguquka. Ukufakwa komklamo osizwa ngekhompyutha (i-CAD) kanye nesofthiwe yokukhiqiza ikhompyutha (CAM) kuvumela ukusikeka okuyinkimbinkimbi nokunembayo, okusekela inkambiso ebheke ku-Industrial 4.0. Izitayela zomphakathi, njengokugxila okwandayo ekuzinzeni, nazo zinomthelela emakethe, ngabakhiqizi abakha imishini eco-friendly edla amandla amancane futhi ikhiqize ukungcola okuncane.

Amaphuzu obuhlungu bekhasimende, njengezindleko eziphezulu zokuqala kanye nezidingo zokunakekela, adingidwa ngentuthuko kwezobuchwepheshe kanye nokwethulwa kwemishini ethengekayo nesebenziseka kalula. Amasu okubeka uphawu lomkhiqizo agxile ekugqamiseni ukwethembeka, ukunemba, kanye nokuguquguquka kwezinto ezisika i-acrylic laser, kuyilapho amasu okuhlukanisa egcizelela izici eziyingqayizivele njengesivinini sokusika esithuthukisiwe, ukuhlanganiswa kwesofthiwe okuthuthukisiwe, nezindleko zokusebenza eziphansi. Izimakethe ze-Niche, njengokukhiqizwa kwezinto zokuhlobisa eziphezulu kanye nezimpawu ezenziwe ngokwezifiso, zinikeza amathuba abalulekile okukhula kubakhiqizi.

Izinto Ezibalulekile Lapho Ukhetha I-Acrylic Laser Cutter

Lapho ukhetha i-acrylic laser cutter, kubalulekile ukucabangela izici ezihlukahlukene ukuze uqinisekise ukuthi umshini uhlangabezana nezidingo zakho ezithile. Lezi zici zifaka uhlobo lwe-laser, amandla, isivinini sokusika, ukunemba, nezici ezengeziwe. Ngayinye yalezi zici idlala indima ebalulekile ekusebenzeni nasekufanelekeni kwe-laser cutter yezinhlelo zokusebenza ezahlukene.

Uhlobo lwe-Laser

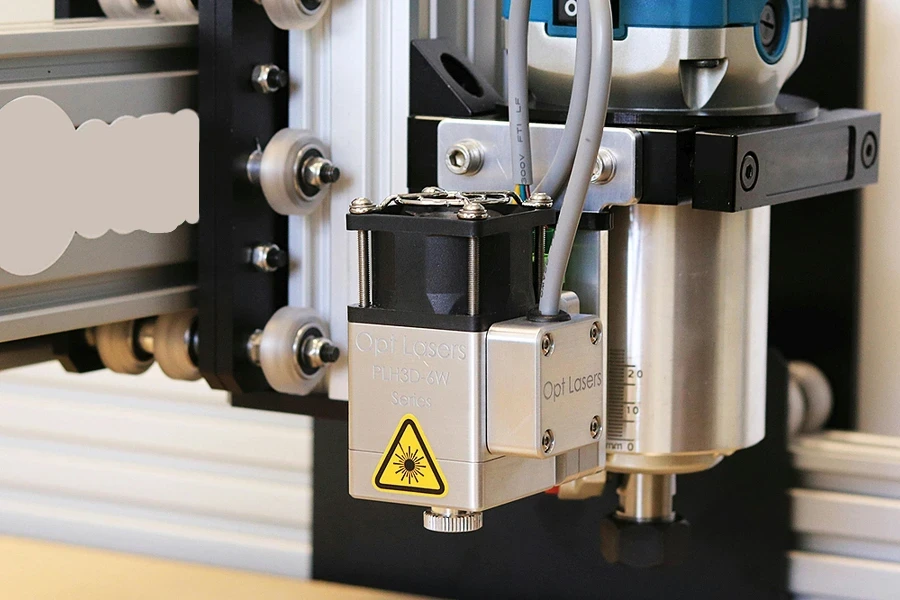

Uhlobo lwe-laser olusetshenziswa kusisiki se-laser ye-acrylic luthinta kakhulu ukusebenza kwayo nobubanzi bokusebenza. Izinhlobo ezivame kakhulu zamalaser asetshenziswa kule mishini amalaser e-CO2 nama-fiber lasers.

Amalaser e-CO2 asetshenziswa kabanzi ngenxa yokusebenza kahle kwawo ekusikeni nasekuqopheni izinto ze-acrylic. Asebenza kubude begagasi obulinganiselwa ku-10.6 µm, okuwenza asebenze kakhulu ezintweni ezingezona ezensimbi. Ama-laser e-CO2 aziwa ngokuphuma kwawo kwamandla okuqhubekayo kanye nekhono lokukhiqiza ukusikeka kwekhwalithi ephezulu enemiphetho ebushelelezi.

Ngakolunye uhlangothi, ama-laser e-fiber awavamile ukusetshenziselwa ukusika i-acrylic kodwa anikeza izinzuzo mayelana nokusebenza kahle kwamandla nokuphila isikhathi eside. Ama-fiber lasers asebenza ngobude obungafinyelela ku-1.064 µm, afaneleka kakhulu ukusikwa kwensimbi. Kodwa-ke, kuzinhlelo zokusebenza ezithile ezidinga ukunemba okuphezulu, njengokuqoshwa okuningiliziwe, ama-fiber lasers angaba inketho.

Power

Amandla e-laser ayisici esibalulekile esinquma isivinini sokusika namandla okujiya komsiki we-laser we-acrylic. Amandla e-laser akalwa ngama-watts (W), kanye namazinga wamandla ajwayelekile wokusika i-acrylic ibanga ukusuka ku-40W ukuya ku-150W noma ngaphezulu, kuye ngohlelo lokusebenza.

Ukusika amashidi e-acrylic aminyene, amazinga aphezulu amandla ayadingeka ukuze kuqinisekiswe ukusikeka okuhlanzekile nokusebenza kahle. Isibonelo, i-laser engu-100W CO2 ingasika i-acrylic engu-10mm ewugqinsi kalula, kuyilapho i-laser engu-40W ingase ibe nzima nogqinsi olunjalo. Amandla aphezulu aphinde ahumushe isivinini sokusika esisheshayo, esingathuthukisa ukukhiqiza kuzilungiselelo zezimboni.

Kodwa-ke, amazinga aphezulu wamandla aphinde asho ukwanda kokusetshenziswa kwamandla kanye nokukhathazeka okungenzeka kube nokuphepha. Kubalulekile ukulinganisa izimfuneko zamandla nohlelo oluhlosiwe ukuze ugweme izindleko ezingadingekile nezingozi.

Isivinini sokusika

Isivinini sokusika singesinye isici esibalulekile, ikakhulukazi ezindaweni zokukhiqiza zevolumu ephezulu. Ijubane lokusika le-acrylic laser cutter lithonywa amandla e-laser, uhlobo lwempahla ye-acrylic, nobukhulu bempahla.

Izisiki ze-Acrylic laser ezinamazinga aphezulu amandla ngokuvamile zinikeza isivinini sokusika esisheshayo, esinganciphisa kakhulu isikhathi sokukhiqiza. Isibonelo, i-laser cutter engu-100W CO2 ingafinyelela isivinini sokusika esingafika ku-300 mm/s nge-acrylic engu-3mm obukhulu, kuyilapho i-laser engu-50W ingase ifinyelele kuphela ku-150 mm/s ngogqinsi olufanayo.

Kubalulekile futhi ukucabangela ikhwalithi yokusika ngesivinini esihlukile. Izivinini eziphakeme kwesinye isikhathi zingaholela ekwehliseni ukunemba namaphethelo amaholoholo, ngakho ukuthola ibhalansi elungile phakathi kwejubane nekhwalithi kubalulekile.

Ukunemba Nokunemba

Ukunemba nokunemba kubaluleke kakhulu uma kuziwa ekusikeni nge-laser, ikakhulukazi ezinhlelweni ezidinga imiklamo eyinkimbinkimbi kanye nokuqoshwa okuningiliziwe. Ukunemba kwe-acrylic laser cutter kuthonywa ikhwalithi ye-laser ye-laser, izingxenye zomshini womshini, nesofthiwe yokulawula.

Amalaser ekhwalithi ephezulu e-CO2 anobubanzi be-beam obuncane angafinyelela ukusikeka okunembile ngokubekezelela okuphansi njengokungu-0.1 mm. Izingxenye zemishini, njengesistimu yokunyakaza kanye nekhanda lokusika, nazo zidlala indima ebalulekile ekugcineni ukunemba. Imishini enamasistimu okulawula ukunyakaza athuthukile nokwakhiwa okuqinile ingaletha imiphumela engaguquki nephindaphindekayo.

Ngaphezu kwalokho, isofthiwe yokulawula esetshenziswa kusisiki se-laser ingathuthukisa ukunemba ngokuvumela ukulungiswa okuhle nokunikeza izici ezifana nokugxila okuzenzakalelayo nokuqapha kwesikhathi sangempela. Ukutshala imali emshinini onamakhono esoftware athuthukile kungathuthukisa kakhulu ukunemba okuphelele kanye nekhwalithi yokusikeka.

Izici ezengeziwe

Lapho ukhetha i-acrylic laser cutter, izici ezengeziwe zingathuthukisa ukuguquguquka komshini kanye nokusebenziseka kalula. Ezinye izici ezibalulekile okufanele uzibheke zifaka i-auto-focus, okunamathiselwe kwi-rotary, i-air assist, nezici zokuphepha. I-Auto-focus ilungisa ngokuzenzakalelayo ukugxila kwe-laser beam ngokusekelwe kugqinsi lwezinto, iqinisekisa ukusebenza okuhle kokusika. Izinamathiselo ezijikelezayo zingabaluleka ekusikeni nasekuqopheni izinto eziyi-cylindrical. Ukusiza komoya kuphephula umoya ogelezayo endaweni yokusika ukuze kukhishwe udoti futhi kuvimbele ukushisa ngokweqile, okuholela ekusikeni okuhlanzekile. Izici zokuphepha njengezinkinobho zokumisa izimo eziphuthumayo, izindawo ezivalekile, nezixhumi ze-laser zibalulekile ukuze kuqinisekiswe ukusebenza okuphephile.

Ukucabangela lezi zici ezengeziwe kungakusiza ukhethe i-acrylic laser cutter engagcini nje ngokuhlangabezana nezidingo zakho zokusika kodwa futhi ethuthukisa ukukhiqiza nokuphepha.

Ubuchwepheshe obuthuthukisiwe kuma-Acrylic Laser Cutters

Imboni ye-acrylic laser cutter ibone intuthuko enkulu kwezobuchwepheshe, okuholela ekusebenzeni okuthuthukisiwe, ukusebenza kahle, kanye nokuguquguquka. Lokhu kuthuthuka kufaka phakathi izinto ezintsha emithonjeni ye-laser, amasistimu okulawula ukunyakaza, kanye nezindawo zokusebenzelana nabasebenzisi.

Emisha emithonjeni ye-Laser

Enye yentuthuko ephawuleka kakhulu kubasiki be-laser be-acrylic ukuthuthukiswa kwemithombo ye-laser enamandla amakhulu, esebenza kahle kakhulu. Amalaser esimanje e-CO2 asesebenza kahle kakhulu, enikeza amandla aphezulu okukhipha amandla ngokusetshenziswa okuphansi kwamandla. Lokhu kuthuthukiswa akugcini nje ngokuthuthukisa ukusika ukusebenza kodwa futhi kunciphisa izindleko zokusebenza.

Ukwengeza, inqubekelaphambili kubuchwepheshe be-fiber laser yenze kwaba nokwenzeka ukusebenzisa la ma-lasers ezinhlelweni ezithile zokusika i-acrylic. Ama-fiber lasers anikeza izinzuzo ezifana nokuphila isikhathi eside, izidingo zokukhanda eziphansi, namandla aphezulu uma kuqhathaniswa namalaser endabuko e-CO2. Lawa ma-laser anganikeza ukusikeka okunembile kanye nokuqoshwa, okuwenza afanelekele umsebenzi onemininingwane.

Amasistimu Okulawula Ukunyakaza Athuthukisiwe

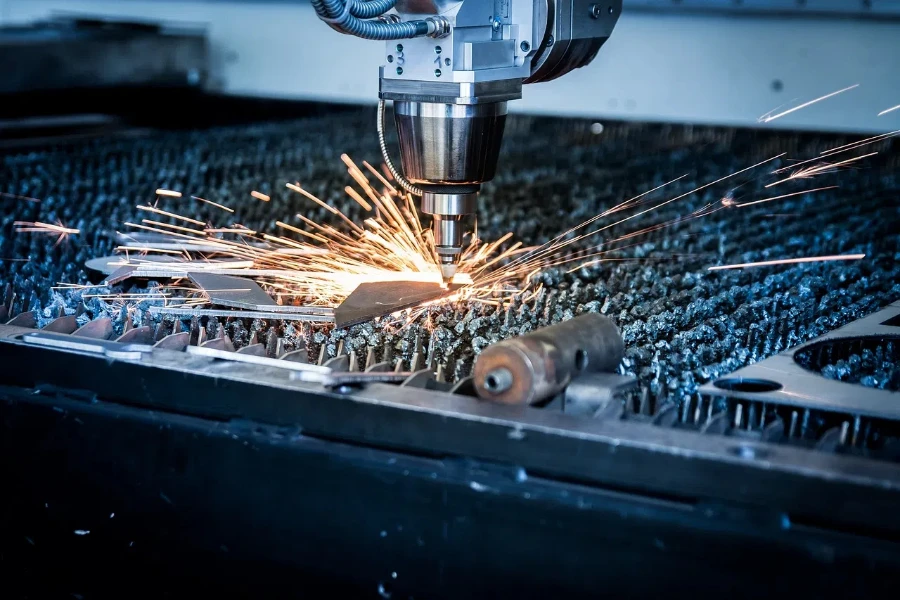

Amasistimu okulawula ukunyakaza kuma-aclic laser cutters nawo abone ukuthuthuka okukhulu. Amasistimu athuthukile manje ahlanganisa imihlahlandlela yomugqa enembe kakhulu, ama-servo motors, nezindlela zokulawula iluphu evaliwe. Lezi zingxenye zisebenza ndawonye ukuze zilethe ukunyakaza okushelelayo nokunembile, okuholela ekusikekeni okunembayo kanye nokuqoshwa.

Ukuhlanganiswa kwezinhlelo ze-gantry kanye nezingalo zerobhothi kuye kwathuthukisa nakakhulu ukuguquguquka kwe-acrylic laser cutters. Lezi zinhlelo zivumela ukunyakaza kwama-axis amaningi, okwenza amaphethini okusika ayinkimbinkimbi kanye nokuqoshwa kwezinhlangothi ezintathu. Ngekhono lokuphatha imiklamo eyinkimbinkimbi, abasiki besimanje be-acrylic laser bangahlangabezana nezidingo zezimboni ezihlukahlukene, okuhlanganisa izimpawu, ukukhangisa, kanye nokukhiqiza.

I-interfaces neSoftware Esebenziseka kalula

I-interface yomsebenzisi kanye nesofthiwe yabasiki be-laser ye-acrylic isibe enembile futhi inothile ngesici. Imishini yesimanje iza ifakwe ukuxhumana kwesikrini esithintwayo, okuvumela ukuzulazula nokulawula okulula. Isofthiwe esetshenziswa kule mishini inikeza izici ezithuthukile ezifana nokuqapha kwesikhathi sangempela, ukugxila okuzenzakalelayo, namalabhulali wezinto ezibonakalayo.

Imitapo yolwazi yezinto ezibonakalayo ihlinzeka ngemingcele esethwe ngaphambilini yezinhlobo ezahlukene ze-acrylic, iqinisekisa ukusebenza kahle kokusika ngaphandle kwesidingo sokulungiswa ngesandla. Ukuqapha ngesikhathi sangempela kuvumela opharetha ukulandelela inqubo yokusika futhi benze izinguquko ezidingekayo endizeni, ukuthuthukisa ukusebenza kahle nokunciphisa amaphutha.

Ngaphezu kwalokho, izixazululo zesoftware esekwe emafini zinika amandla ukusebenza okude nokuqapha abasiki be-acrylic laser. Leli khono linenzuzo ikakhulukazi ezikhungweni zokukhiqiza ezinkulu, lapho imishini eminingi ingaphathwa futhi iqashwe endaweni emaphakathi.

Ukusebenza kahle kwamandla kanye nokucatshangelwa kwemvelo

Ukusebenza kahle kwamandla kanye nomthelela wemvelo kuyizinto ezibaluleke kakhulu lapho kukhethwa i-acrylic laser cutter. Imishini yesimanje iklanyelwe ukunciphisa ukusetshenziswa kwamandla nokunciphisa ukumosha, okunomthelela ohlelweni lokukhiqiza oluzinzile.

Energy Efficiency

Ukuthuthuka kwezobuchwepheshe be-laser kuholele ekuthuthukisweni kwemithombo ye-laser eyonga kakhulu. Ama-laser angu-CO2 anamandla aphezulu manje anikeza ukusebenza kahle kwamandla okungcono, ehlisa ukusetshenziswa kwamandla okuphelele komshini. Ama-laser ama-fiber, aziwa ngokusebenza kahle kwamandla aphezulu, angaqhubeka nokunciphisa izindleko zokusebenza.

Ngaphezu kwemithombo ye-laser ephumelelayo, abasiki besimanje be-laser ye-acrylic bahlanganisa izici zokonga amandla njengezindlela zokulinda ezizenzakalelayo nezinhlelo zokuphatha amandla. Lezi zici zisiza ukunciphisa ukusetshenziswa kwamandla ngezikhathi zokungenzi lutho, zibe negalelo ekwehliseni izikweletu zikagesi kanye ne-carbon footprint encane.

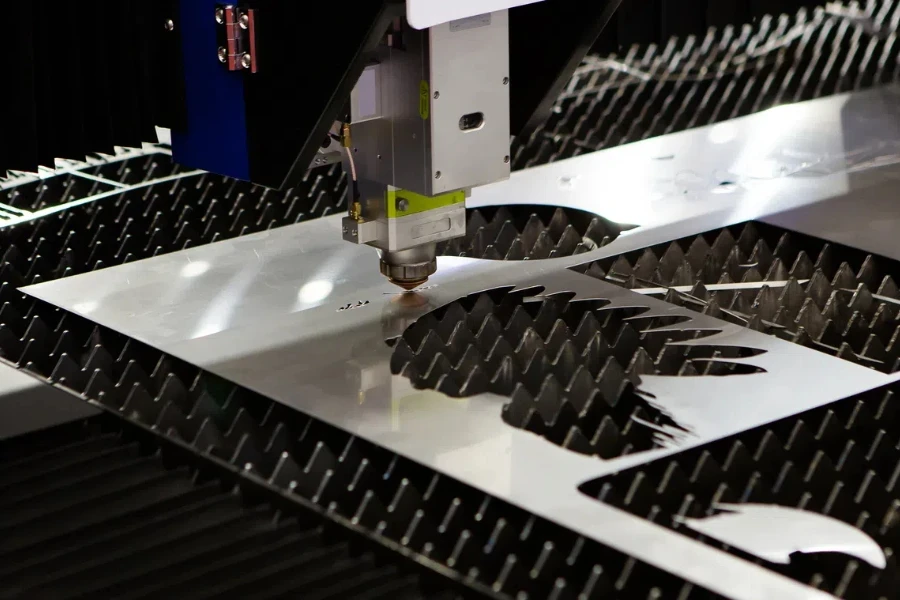

Ukuncishiswa Kwemfucuza

Ukuncishiswa kwemfucuza kungenye ingxenye ebalulekile yokukhiqiza okusimeme. Ama-acrylic laser cutters aklanyelwe ukukhulisa ukusetshenziswa kwezinto ezibonakalayo futhi anciphise imfucuza. Isofthiwe ethuthukisiwe yokuzalela ilungiselela kahle ukuhlelwa kwamaphethini okusika, inciphisa ukumosheka kwezinto futhi iqinisekise ukusetshenziswa kahle kwamashidi e-acrylic.

Ngaphezu kwalokho, amasistimu okusiza komoya kubasiki besimanje be-laser asiza ukususa udoti futhi avimbele ukunqwabelana kwezinto, okuholela ekusikekeni okuhlanzekile kanye nokuncipha kwemfucuza. Lezi zinhlelo ziphinde zithuthukise ikhwalithi isiyonke yokusikwa, ukunciphisa isidingo sokuphinda kusetshenziswe futhi kuncishiswe nakakhulu ukungcola.

Impembelelo yemvelo

Umthelela wemvelo we-acrylic laser cutters udlulela ngalé kokusetshenziswa kwamandla kanye nokunciphisa imfucuza. Ukusetshenziswa kwezinto ezithinta imvelo kanye nezingxenye ekwakhiweni kwemishini nakho kunendima ekusimameni. Abakhiqizi baya ngokuya besebenzisa izinto ezingaphinda zisetshenziswe futhi basebenzise izinqubo zokukhiqiza ezinobungani nemvelo.

Ukwengeza, abanye abasiki be-laser be-acrylic bafakwe izinhlelo zokukhipha umusi ezithwebula futhi zihlunge ukukhishwa okuyingozi okukhiqizwa ngesikhathi sokusika. Lezi zinhlelo zisiza ukugcina indawo yokusebenza ephephile futhi zinciphise ukudedelwa kokungcola emkhathini.

Amazinga Okuphepha kanye Nezitifiketi

Ukuphepha kubaluleke kakhulu lapho usebenzisa ama-aclic laser cutters. Ukunamathela ezindinganisweni zokuphepha nokuthola izitifiketi ezifanele kuqinisekisa ukusebenza okuphephile kwemishini nokuhambisana nezidingo zokulawula.

Izinga Lokuphepha

Abasiki be-laser be-Acrylic kufanele bahambisane namazinga ahlukahlukene okuphepha ukuze baqinisekise ukusebenza okuphephile. E-United States, i-Occupational Safety and Health Administration (OSHA) ilawula amazinga okuphepha emishini ye-laser. Uchungechunge lwe-ANSI Z136 luphinde lulawule amazinga okuphepha nge-laser ezinhlelo zokusebenza ezahlukene, okuhlanganisa izimboni, ezokwelapha, kanye nocwaningo.

Ukuthobelana nalawa mazinga kuhlanganisa ukusebenzisa izici zokuphepha njengezinkinobho zokumisa izimo eziphuthumayo, izindawo ezivalekile ezivikelayo, nezixhumi ze-laser. Lezi zici zisiza ukuvimbela izingozi futhi zivikele opharetha ezingozini ezingaba khona ezihlobene nokusika i-laser.

izitifiketi

Ukuthola izitifiketi ezinhlanganweni ezaziwayo kubonisa ukuzibophezela komkhiqizi ekuphepheni nakwikhwalithi. Izitifiketi ezijwayelekile zabasiki be-laser ye-acrylic zihlanganisa ukumaka i-CE (Conformité Européenne), okubonisa ukuhambisana nezindinganiso zokuphepha zase-Europe, ezempilo, kanye nokuvikelwa kwemvelo.

Ezinye izitifiketi, njenge-ISO 9001 kanye ne-ISO 14001, zifakazela ukunamathela komkhiqizi ekuphathweni kwekhwalithi nezinhlelo zokuphatha imvelo, ngokulandelana. Lezi zitifiketi zinikeza isiqinisekiso sokuthi i-acrylic laser cutter ihlangabezana namazinga aqinile okuphepha kanye nekhwalithi.

Izinqubo Zokuqeqesha Nokuphepha

Ngaphezu kokuhambisana namazinga okuphepha kanye nezitifiketi, ukuqeqeshwa okufanele kanye nezinqubo zokuphepha kubalulekile ekusebenzeni okuphephile. Ama-opharetha kufanele bathole ukuqeqeshwa okuphelele mayelana nokusetshenziswa kwe-acrylic laser cutters, okuhlanganisa imigomo yokuphepha, ukusebenza komshini, nezinqubo zokuwulungisa.

Ukusebenzisa izinqubo zokuphepha, njengokuhlola nokunakekelwa okuvamile, kungasiza ekuhlonzeni izinkinga ezingaba khona futhi kuvimbele izingozi. Ukuhlinzeka opharetha ngemishini yokuzivikela yomuntu siqu (i-PPE), njengezibuko zokuphepha ze-laser namagilavu, kuthuthukisa ukuphepha ngesikhathi sokusebenza.

Ukuhambisana Nokuthuthukiswa Kwekusasa

Ukutshala imali kusisiki se-laser ye-acrylic ehambisana nokuthuthukiswa kwesikhathi esizayo kuqinisekisa ukusebenziseka kwesikhathi eside nokuvumelana nezimo kubuchwepheshe obuguqukayo. Ukuhambisana nokuthuthukiswa kunganweba isikhathi sokuphila komshini futhi kuthuthukise ukusebenza kwawo ngokuhamba kwesikhathi.

Design Modular

Abasiki be-laser be-Acrylic abanomklamo we-modular bavumela ukuthuthukiswa okulula nokwenza ngokwezifiso. Izingxenye ze-modular, njengemithombo ye-laser, amasistimu anyakazayo, nesofthiwe yokulawula, ingashintshwa noma ithuthukiswe ngaphandle kwesidingo sokuthenga umshini omusha. Lokhu kuvumelana nezimo kwenza amabhizinisi akwazi ukuzivumelanisa nezimfuneko ezishintshayo futhi ahlanganise nobuchwepheshe bamuva.

Ukuthuthukiswa Kwesofthiwe

Ukuthuthukiswa kwesofthiwe kudlala indima ebalulekile ekugcineni ukusebenza nokusebenza kwezisiki ze-acrylic laser. Abakhiqizi bavame ukukhipha izibuyekezo zesofthiwe ezifaka izici ezintsha, ama-algorithm athuthukisiwe, nokulungiswa kweziphazamisi. Ukuqinisekisa ukuthi isofthiwe yokulawula ye-laser cutter ibuyekezwa njalo kungathuthukisa amakhono ayo futhi kwandise isikhathi sayo sokuphila.

Ukuhlanganisa nezinye izinhlelo

Ukuhambisana namanye amadivaysi namasistimu kungenye indlela ebalulekile. Ama-acrylic laser cutters angahlanganiswa nesoftware ye-computer-aid design (CAD), izinhlelo ze-enterprise resource planning (ERP), neminye imishini yokukhiqiza inikeza ukuguquguquka okukhulu nokusebenza kahle. Lokhu kuhlanganiswa kwenza kube lula inqubo yokukhiqiza futhi kwenza ukuxhumana okungenazihibe phakathi kwamasistimu ahlukene.

Ukufakazela Ikusasa

Ukuqinisekisa ikusasa i-acrylic laser cutter kuhlanganisa ukukhetha umshini ongamela intuthuko elindelwe kwezobuchwepheshe. Isibonelo, ukukhetha i-laser cutter enamandla anele kanye nokunemba kwezinhlelo zokusebenza ezingaba khona zesikhathi esizayo kungavimbela isidingo sokuthuthukiswa okumba eqolo noma ukushintshwa.

Ukwengeza, ukucabangela amathrendi avelayo nobuchwepheshe, obufana ne-automation kanye ne-artificial intelligence (AI), kungasiza ukufakazela ukutshalwa kwezimali esikhathini esizayo. Imishini efakwe izici ezizenzakalelayo, njengezikhali zamarobhothi namasistimu okuthutha, ingathuthukisa ukukhiqiza futhi yehlise izindleko zabasebenzi.

Isifinyezo

Ukukhetha i-acrylic laser cutter efanele kuhilela ukucabangela izici ezihlukahlukene ezifana nohlobo lwe-laser, amandla, isivinini sokusika, ukunemba, nezici ezengeziwe. Ukuthuthuka kwezobuchwepheshe kuholele ekuthuthukisweni kwemishini esebenza kahle kakhulu futhi eguquguqukayo, enikeza ukusebenza okuthuthukisiwe nokusimama. Ukuthobela izindinganiso zokuphepha kanye nokuthola izitifiketi ezifanele kuqinisekisa ukusebenza okuphephile nokuhambisana nemithethonqubo. Ukuhambisana nokuthuthukiswa okuzayo kwandisa isikhathi sokuphila komshini futhi kuvumela ukuzivumelanisa nobuchwepheshe obuguqukayo. Ngokuhlola ngokucophelela lezi zici, amabhizinisi angenza izinqumo ezinolwazi futhi atshale imali kubasiki be-acrylic laser abahlangabezana nezidingo zabo kanye nezidingo zabo ezithile.