Ngo-2025, ukukhiqizwa okunembayo kuyaqhubeka nokubusa indawo yezimboni, okugqugquzela ukuvela kobuchwepheshe bokusika ipayipi le-laser. Le ndatshana ihlinzeka ngokuhlaziywa okujulile kwemakethe, izici ezibalulekile okufanele zicatshangelwe lapho kukhethwa imishini, nokuthi lezi ntuthuko zingazuzisa kanjani abathengi abangochwepheshe kanye nokusebenza kwabo. Ukushintshela embhalweni oyinhloko, sihlola izici ezibalulekile ezizoqondisa izinqumo zakho zokuthenga.

Okuqukethwe:

- Imakethe Yomhlaba Wonke Yokusika Ipayipi Laser: Uhlolojikelele Oluphelele

- Ukuhlaziywa Okujulile Kwemakethe Yokusika I-Pipe Laser

- Izinto Ezibalulekile Lapho Ukhetha Imishini Yokusika I-Pipe Laser

- Ukuthuthukisa Ukuphumelela Kokukhiqiza Ngokusika i-Pipe Laser

- Ukutshala imali ekusaseni lezokukhiqiza

– Imicabango yokugcina

I-Global Market for Pipe Laser Cutting: Uhlolojikelele Oluphelele

Imakethe yokusika i-laser yamapayipi ikhombise ukukhula okukhulu ngenxa yesidingo esikhulayo sokukhiqiza okunembayo kuzo zonke izimboni ezahlukahlukene. Imakethe yomhlaba wonke yomshini wokusika i-laser, okubandakanya ukusika i-laser yamapayipi, ibibiza ama-dollar ayizigidi eziyizinkulungwane ezingama-35.4 ngo-2023 futhi kulindeleke ukuthi ifinyelele ku-USD 49.3 billion ngo-2030, ikhula ku-CAGR ka-4.9%. Lokhu kukhula kuqhutshwa ukuthuthuka kwezobuchwepheshe be-laser kanye nesidingo esikhulayo sokunemba ezinqubweni zokukhiqiza, ikakhulukazi emikhakheni yezimoto, i-aerospace, kanye ne-electronics.

Isifunda sase-Asia-Pacific sibusa imakethe yomshini wokusika i-laser, okubandakanya ukusika kwe-laser yamapayipi. Le makethe kulindeleke ukuthi ikhule ku-CAGR ka-4.6%, igqugquzelwa ukuthuthuka kwezimboni kanye nokwamukelwa kobuchwepheshe bokukhiqiza obuthuthukile. I-China idlala indima ebalulekile, njengoba imakethe yayo kulindeleke ukuthi ifinyelele ku-USD 7.8 billion ngo-2030. I-United States iphinde imele imakethe ebalulekile, elinganiselwa ku-USD 9.6 billion ngo-2023, okubonisa isidingo esikhulu sobuchwepheshe bokusika i-laser eNyakatho Melika.

Abadlali ababalulekile emakethe yokusika i-laser yamapayipi bahlanganisa i-Alpha Laser GmbH, i-AMADA WELD TECH Inc., i-Bystronic Group, i-Coherent Corp., ne-TRUMPF SE + Co. KG. Lezi zinkampani zihola emisha, ngokuqhubekayo zithuthukisa ubuchwepheshe obusha futhi zandise imigqa yemikhiqizo yazo ukuze zihlangabezane nezidingo zemakethe.

Ukuhlaziywa Okujulile Kwemakethe Yokusika I-Pipe Laser

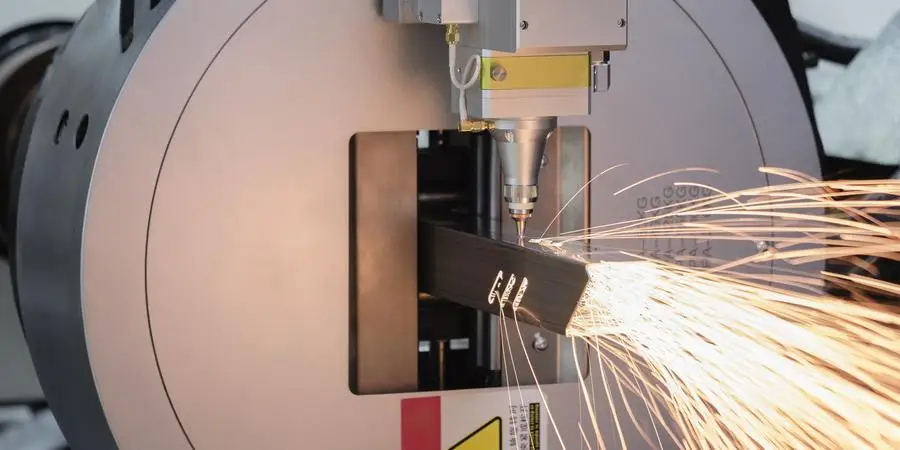

Imakethe yokusika i-laser yamapayipi ihamba phambili ekuletheni ukunemba okuphezulu nokusebenza kahle ekusikeni izinto ezahlukahlukene ezifana nezinsimbi namapulasitiki. Imibandela yokusebenza ebalulekile yemishini yokusika i-laser ihlanganisa isivinini sokusika, ukunemba, kanye nokuguquguquka kwezinto ezibonakalayo. Ama-laser e-fiber athandwa kakhulu ngenxa yokusebenza kahle kwawo okuphezulu, isivinini sokusika ngokushesha, nezindleko eziphansi zokusebenza uma kuqhathaniswa namalaser endabuko e-CO2.

Imakethe inokuncintisana kakhulu, nabathengisi abahlukahlukene abanikela kakhulu. I-FPNV Positioning Matrix ihlukanisa laba bathengisi ngamaquadrants amane—Ingaphambili, i-Pathfinder, i-Niche, ne-Vital—ngokusekelwe kumasu abo ebhizinisi namazinga okwaneliseka komkhiqizo. Lokhu kusiza amabhizinisi akhethe izixazululo zokusika i-laser ezihlangabezana nezidingo zabo kangcono.

Izinqubo ezintsha zakamuva zihlanganisa ukuhlanganisa imishini yokusika i-laser nesofthiwe ye-CAD ne-CAM, okuvumela ukusikeka okuyinkimbinkimbi nokunembayo. Lokhu kusekela ukuthambekela kwe-Industrial 4.0. Ukuthuthukiswa kwemishini yokusika i-fiber laser kuvule izinhlelo zokusebenza ezintsha, ikakhulukazi ezimbonini zezimoto neze-electronics, lapho izinto ezifana ne-aluminium nethusi zisetshenziswa kakhulu.

Izici zomnotho ezithonya imakethe zifaka phakathi isidingo esikhulayo sekhwalithi ephezulu, izingxenye eziyinkimbinkimbi ezimbonini ezahlukahlukene. Ukushintshela ezintweni ezingasindi emkhakheni wezimoto kanye ne-aerospace nakho kuqhuba ukwamukelwa kwemishini yokusika i-laser. Ukwengeza, umkhuba obheke ku-automation kanye nokukhiqiza ngobuhlakani ukhulisa isidingo semishini yokusika i-laser engahlanganiswa emigqeni yokukhiqiza ezenzakalelayo, ithuthukise ukukhiqiza kanye nokunciphisa izindleko zabasebenzi.

Ukuziphatha kwabathengi kukhombisa ukuthanda okukhulayo kokukhiqizwa kwedijithali kanye nokukhiqizwa okwenziwe ngendlela oyifisayo, amaqoqo amancane. Imishini yokusika i-laser inikeza ukuguquguquka kokushintsha ngokushesha phakathi kwemisebenzi yokusika ehlukene ngaphandle kokusebenza kabusha okubanzi. Iziteshi zokusabalalisa zale mishini zihlanganisa ukuthengisa okuqondile, abasabalalisi, nezinkundla ze-inthanethi, ngokuncanyelwayo kwezisombululo eziphelele ezihlanganisa ukufakwa, ukuqeqeshwa, nokusekelwa ngemva kokuthengisa.

Izinselelo zamakhasimende emakethe yokusika ipayipi ye-laser ngokuvamile zihlanganisa izindleko eziphezulu zokuqala zemishini kanye nesidingo sabaqhubi abanamakhono. Abathengisi babhekana nalezi zinkinga ngokwakha izixhumanisi ezisebenziseka kalula futhi banikeze ukuqeqeshwa nokusekelwa okubanzi. Umkhuba obheke ekwenzeni idijithali kanye nezixazululo zesofthiwe ezithuthukisiwe futhi usiza ukwenza lula ukusebenza kanye nokunciphisa ijika lokufunda kubasebenzisi abasha.

Izinto Ezibalulekile Lapho Ukhetha Imishini Yokusika Ipayipi Laser

Ukukhetha umshini wokusika we-laser wepayipi ofanele kuhilela ukuhlola izici ezimbalwa ezibalulekile ukuze uqiniseke ukuthi uhlangabezana nezidingo zakho ezithile zokusebenza. Lezi zici zifaka uhlobo lwe-laser, umthamo wamandla, isivinini sokusika, ubukhulu, nezici ezengeziwe ezithuthukisa ukusebenza nokusebenziseka kalula. Ngezansi, sizocubungula ngokuningiliziwe lokhu okucatshangelwayo okuyinhloko.

Uhlobo lwe-Laser

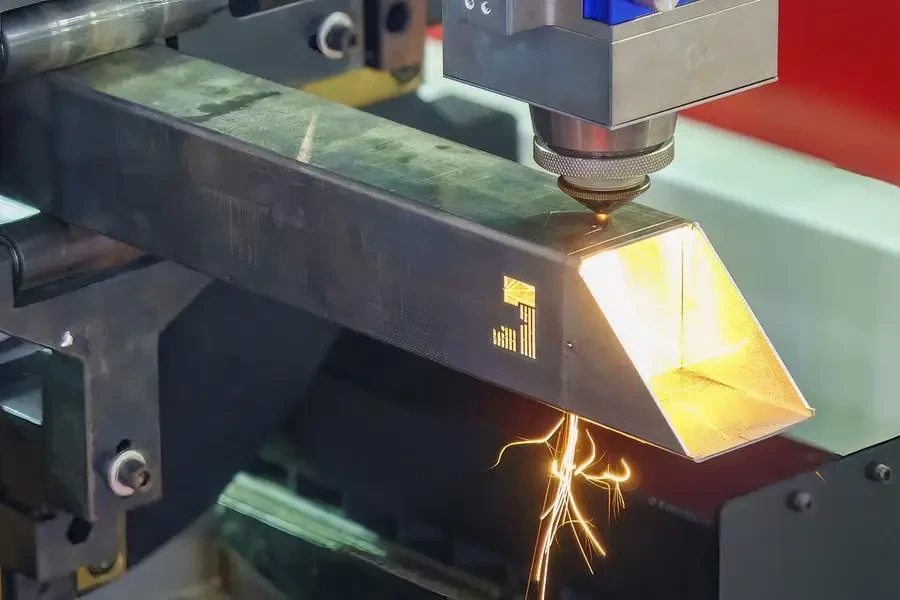

Uhlobo lwe-laser olusetshenziswayo luthinta kakhulu ukusebenza komshini kanye nokufaneleka kwezinto ezihlukahlukene. Izinhlobo ezimbili eziyinhloko zamalaser amalaser e-CO2 nama-laser fiber.

I-CO2 Lasers: Amalaser e-CO2 asebenzisa ingxube yegesi ngokuyinhloko eyakhiwe yi-carbon dioxide. Asebenza kahle kakhulu ekusikeni izinto ezingezona ezensimbi namapayipi ensimbi awugqinsi ngenxa yobude bawo begagasi obude (cishe u-10.6 µm). Lawa ma-laser agcina amazinga wamandla aqhubekayo naphezulu, awenze afanelekele izinhlelo zokusebenza ezidinga ukujula okujulile kokusika. Zilungele izinto ezinjengokhuni, ingilazi, namapulasitiki athile.

I-Fiber Lasers: Ama-fiber lasers asebenzisa imicu yokubona ehlanganiswe nezinto ezingavamile zomhlaba njenge-ytterbium. Akhipha ukukhanya kumaza wamaza amafushane (cishe u-1.064 µm), okuwenza asebenze kahle kakhulu ekusikeni izinsimbi, okufaka insimbi engagqwali, i-aluminium, nethusi. Ama-laser efiber aziwa ngokunemba kwawo okuphezulu, isivinini sokusika ngokushesha, nezindleko zokulungisa eziphansi uma kuqhathaniswa namalaser e-CO2. Usayizi wabo ohlangene nokusebenza kahle kwamandla kubenza badume kakhulu ezinhlelweni zezimboni.

Amandla Amandla

Amandla omshini wokusika i-laser wepayipi, olinganiswa ngama-kilowatts (kW), anquma amandla awo okusika kanye nesivinini.

Ama-Laser Amandla Aphansi (1-3 kW): Lezi zilungele izinto ezisetshenziswayo ezincanyana kanye nezicelo ezingafuneki kangako. Zinikeza ukunemba okuphezulu futhi zingabizi kakhulu ekusebenzeni okuncane kuya kosayizi ophakathi.

Ama-Laser Amandla Aphakathi (3-6 kW): Lokhu kunikeza ibhalansi phakathi kwejubane lokusika nokunemba, okubenza bafaneleke uhla olubanzi lwezinto kanye nobukhulu. Zilungele ukusethwa kokukhiqiza okuphakathi nendawo.

Ama-Lasers Anamandla Anamandla (6-12 kW nangaphezulu): Ama-laser anamandla aphezulu aklanyelwe ukusika izinto eziwugqinsi kanye nokukhiqizwa kwevolumu ephezulu. Banikeza isivinini sokusika esisheshayo futhi sibalulekile ezinhlelweni zokusebenza zezimboni ezisindayo. Nokho, ziza nezindleko eziphezulu zokusebenza futhi zidinga amasistimu okupholisa ayinkimbinkimbi.

Isivinini sokusika

Ukunciphisa isivinini kubalulekile ekukhiqizeni nasekusebenzeni kahle. Kuthonywa amandla e-laser, okokusebenza okusikwayo, kanye nomklamo wonkana womshini.

Uhlobo Material: Izinto ezihlukahlukene zisabela ngendlela ehlukile ekusikeni kwe-laser. Izinsimbi ezifana ne-aluminium nethusi, ezinokusebenza okuphezulu kwe-thermal, zidinga isivinini sokusika esihamba kancane uma siqhathaniswa nensimbi.

Ubukhulu: Izinto eziwugqinsi ngokuvamile zidinga isivinini sokusika esinensayo ukuze kuqinisekiswe ukusika okuhlanzekile nokunembayo. Ama-laser anamandla amakhulu anganqamula izinto eziwugqinsi ngokushesha, kodwa lokhu kubuye kuncike emandleni athile omshini.

Ukunemba kanye Nekhwalithi: Izivinini eziphakeme zokusika kwesinye isikhathi zingafaka engcupheni ikhwalithi nokunemba kokusikwa. Kubalulekile ukuthola ibhalansi ehlangabezana nezidingo zakho zokukhiqiza ngaphandle kokudela ikhwalithi yomkhiqizo oqediwe.

Ubukhulu kanye Nobukhulu Umthamo

Ubukhulu bomshini wokusika we-laser wepayipi kanye nekhono lawo lokusingatha ububanzi obuhlukahlukene bepayipi nobude kuyizinto ezibalulekile zokucatshangelwa.

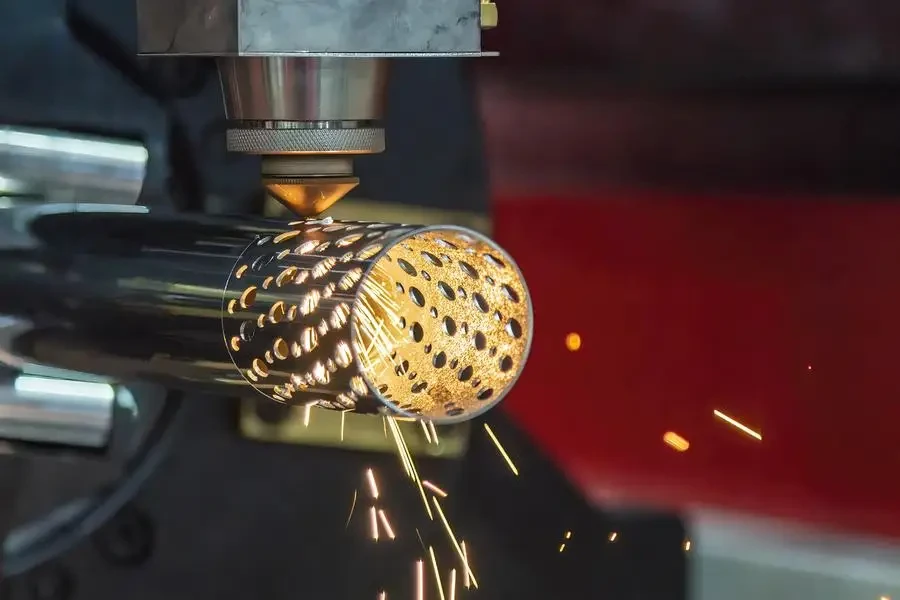

I-Diameter yamaphayiphi: Qinisekisa ukuthi umshini uyakwazi ukumumatha ububanzi bamapayipi okusebenza ngawo. Imishini enama-chuck alungisekayo kanye nezinto ezilungiswayo ingakwazi ukuphatha osayizi abahlukahlukene, inikeze ukuguquguquka okukhulu.

Ukunquma Ubude: Ubude obukhulu bokusika bomshini kufanele bufane nezidingo zakho zokukhiqiza. Eminye imishini inikezela ngemibhede enwetshiwe ukuze ifake amapayipi amade, okubalulekile ezimbonini ezifana nezokwakha nowoyela negesi.

Izinyathelo Zomshini: Cabangela indawo etholakalayo endaweni yakho. Imishini emikhulu ingase inikeze amakhono amaningi kodwa idinga indawo yaphansi eyengeziwe. Qinisekisa ukuthi unesikhala esanele sokusebenza okuphephile nokunakekelwa.

Izici ezengeziwe

Imishini yokusika ipayipi yesimanje ye-laser iza nezici ezahlukahlukene ezithuthukisa ukusebenza kwayo nokusebenziseka kalula.

Ukuzenzekelayo: Amasistimu okulayisha nokuthulula ngokuzenzakalelayo angakhuphula kakhulu umkhiqizo futhi anciphise izindleko zabasebenzi. Bheka imishini enezixazululo ezizenzakalelayo ezididiyelwe ukuze isebenze ngaphandle komthungo.

I-Software kanye Nezinhlelo Zokulawula: Izinhlelo ezithuthukisiwe ze-CNC (Computer Numerical Control) zinikeza ukulawula okunembile phezu kwenqubo yokusika. Izixhumi ezibonakalayo ezisebenziseka kalula nokuhambisana kwesofthiwe kungathuthukisa ukusebenza kahle futhi kunciphise ijika lokufunda kubaqhubi.

Izici Zokuphepha: Qinisekisa ukuthi umshini uthobelana namazinga okuphepha embonini futhi uhlanganisa izici ezifana nezindawo ezivalekile ezivikelayo, izinkinobho zokumisa izimo eziphuthumayo, nezikhiya zokuphepha ze-laser ukuze kuvikelwe opharetha.

Ukugcinwa Nokusekelwa: Cabangela ukutholakala kwezinsizakalo zokunakekela nokusekelwa kobuchwepheshe. Imishini enezingxenye ezifinyeleleka kalula namaphakheji osekelo aphelele inganciphisa isikhathi sokuphumula futhi iqinisekise ukusebenza kahle.

Ukuthuthukisa Ukukhiqiza Ngokuphumelelayo Nge-Pipe Laser Cutting

Ukusebenzisa ipayipi laser cutting ubuchwepheshe kungathuthukisa kakhulu ukukhiqiza ukusebenza kahle ezimbonini ezihlukahlukene. Ngokuqonda izinzuzo nezinselele ezingaba khona, amabhizinisi angasebenzisa kangcono lobu buchwepheshe ukuze bathole imiphumela emihle.

Ukunemba Nokunemba

Imishini yokusika i-laser yamapayipi inikeza ukunemba okungenakuqhathaniswa nokunemba, okubalulekile ekukhiqizeni okuphezulu. Ikhono lokukhiqiza ukusikeka okuyinkimbinkimbi kanye nokuma okuyinkimbinkimbi ngephutha elincane kunciphisa udoti wezinto ezibonakalayo futhi kuqinisekise ukuhambisana ekukhiqizeni.

Ukulahlwa Kwezinto Ezincishisiwe: Ukusikeka okunembile kusho ukumosha izinto ezincane, okuholela ekongeni izindleko kanye nokusetshenziswa kahle kwezisetshenziswa. Lokhu kunemba kubaluleke kakhulu ezimbonini lapho izindleko zempahla ziphezulu.

Ikhwalithi Engaguquki: Ukungaguquguquki kwekhwalithi yokusika kuqinisekisa ukuthi yonke ingxenye ihlangabezana nokucaciswa okudingekayo, kunciphisa isidingo sokusebenza kabusha kanye nokuthuthukisa ikhwalithi yomkhiqizo iyonke.

Isivinini kanye Nokukhiqiza

Isivinini esikhulu sokusika semishini ye-laser sihumushela ekukhiqizeni okwandisiwe. Izikhathi zokusika ezisheshayo zivumela ukusebenza okuphezulu, okwenza amabhizinisi ahlangabezane nezikhathi ezimisiwe futhi andise umthamo wawo wokukhiqiza.

Ukufakwa okuphezulu: Isivinini sokusika esiphezulu sisho ukuthi izingxenye eziningi zingakhiqizwa ngesikhathi esifushane, ukwandisa ukuphuma okuphelele nokunciphisa izikhathi zokuhola.

Ukusebenza kahle Ekukhiqizeni: Izici ezizenzakalelayo nezinhlelo zokulawula ezithuthukisiwe zithuthukisa ukusebenza kahle, okuvumela ukusebenza okuqhubekayo ngokunciphisa isikhathi esincane.

yizinhlobonhlobo

Imishini yokusika i-laser yamapayipi iguquguquka futhi ingakwazi ukuphatha izinto eziningi kanye nezicelo. Lokhu kuguquguquka kubenza bafanelekele izimboni ezahlukene, kusukela kwezezimoto kanye ne-aerospace kuya kwezokwakha nezokukhiqiza.

Ukuphatha Izinto Eziningi: Ikhono lokusika izinto ezihlukene, okuhlanganisa izinsimbi, amapulasitiki, nezinhlanganisela, lenza le mishini ibe yigugu ezidingweni ezihlukahlukene zokukhiqiza.

Ukuguquguquka: Imishini enezilungiselelo ezilungisekayo kanye nezingxenye ezishintshayo ingakwazi ukuzivumelanisa ngokushesha nezimfuneko ezihlukene zokukhiqiza, inikeze ukuguquguquka okukhulu ekusebenzeni.

Ukutshala imali ekusaseni lezokukhiqiza

Ukwamukelwa kobuchwepheshe bokusika i-laser yamapayipi kumelela ukutshalwa kwezimali okubalulekile esikhathini esizayo sokukhiqiza. Ngokuhlala ngaphambi kwentuthuko yezobuchwepheshe kanye nokuthambekela komkhakha, amabhizinisi angagcina umkhawulo wokuncintisana futhi aqhubekisele phambili emisha.

Ukuthuthukiswa kwezobuchwepheshe

Intuthuko eqhubekayo kubuchwepheshe be-laser ithuthukisa ukusebenza kahle, ukunemba, kanye nokusebenza kahle kwezindleko. Ukuhlala unolwazi ngentuthuko yakamuva kuqinisekisa ukuthi amabhizinisi angakwazi ukusebenzisa izixazululo ezisezingeni eliphezulu ngezidingo zawo zokukhiqiza.

I-Emerging Technologies: Ubuchwepheshe obufana ne-AI nokufunda komshini kuhlanganiswa ezinhlelweni zokusika i-laser, ukuhlinzeka ngokulungiswa okubikezelwayo, ukuqapha kwesikhathi sangempela, kanye nokwenza kahle kwemingcele yokusika.

Ukusimama: Imishini emisha yokusika i-laser iklanywe kucatshangwa ngokusebenza kahle kwamandla, inciphisa umthelela wendawo kanye nezindleko zokusebenza. Ukutshala imali kubuchwepheshe obuzinzile kuhambisana nezinkambiso zomhlaba jikelele eziya kuzinqubo zokukhiqiza ezinobungani bemvelo.

Amathrendi Wemboni

Ukuqonda izitayela zemboni kanye nezidingo zemakethe kubalulekile ekwenzeni izinqumo zokutshala izimali unolwazi. Isidingo esikhulayo semikhiqizo eyenziwe ngokwezifiso kanye nokushintshela ekukhiqizeni okuhlakaniphile kuyizitayela ezibalulekile ezakha ikusasa lomkhakha.

Ukwenza ngokwezifiso: Ikhono lokukhiqiza izingxenye ezenziwe ngezifiso nezingxenye ngokushesha nangempumelelo liya ngokuya libaluleke kakhulu. Ubuchwepheshe bokusika i-laser busekela lo mkhuba ngokunikeza ukunemba okuphezulu nokuguquguquka.

I-Smart Manufacturing: Ukuhlanganiswa kwezimiso ze-IoT (I-inthanethi Yezinto) kanye ne-Industrial 4.0 kuguqula izinqubo zokukhiqiza. Imishini yokusika i-laser ehlakaniphile enokuxhumana okuthuthukile namandla okuhlaziya idatha ihamba phambili kulolu shintsho.

Imicabango Final

Ukukhetha umshini wokusika we-laser wepayipi ofanele kudinga ukucatshangelwa ngokucophelela kwezici ezihlukahlukene, kusukela kuhlobo lwe-laser namandla omthamo wokusika isivinini kanye nezici ezengeziwe. Ngokuqonda lezi zici ezibalulekile, amabhizinisi angenza izinqumo ezinolwazi ezithuthukisa ukusebenza kahle kwawo kokukhiqiza futhi ziqhubekise ukukhula kwesikhathi esizayo.