Imishini yokupulasitela usimende ilethe uguquko oluguquguqukayo embonini yezokwakha ngokwenza kanye nokwenza lula inqubo yokufaka ukhonkolo owenziwe usimende. Le mishini inezinzuzo eziningi, okuhlanganisa ukukhiqiza okukhulayo, ukungaguquguquki okuthuthukisiwe, nokuncipha kwezindleko zabasebenzi. Kodwa-ke, imakethe igcwele abakhiqizi abaningi, okwenza kube inselele ukuthola umshini ofanele ohlangabezana nezidingo zakho.

Lesi sihloko sizohlola izici ezibalulekile lapho uthenga imishini yokupulasitela usimende. Izophinde ixoxe ngesabelo semakethe semishini yokufafaza neyoplasta futhi ihlole izinhlobo ezahlukene zemishini ekhona.

Okuqukethwe

Isabelo semakethe semishini yokufafaza nokuplasta

Izinhlobo zemishini yokupulasitela usimende

Izinto okufanele zicatshangelwe lapho uthenga imishini yokupulasitela usimende

Isiphetho

Isabelo semakethe semishini yokufafaza nokuplasta

Umbiko okhishwe ngu I-Business Wire kukhombisa ukuthi kusukela ngo-2021, imakethe yokufafaza nokunamathisela imishini ikhombise ukuqina kwayo ngenani lama-dollar ayizigidi eziyizinkulungwane ezingama-2.5. Imboni ilindele ukukhula okwengeziwe, okulindelwe ukuthi ifinyelele ezigidini eziyizigidi eziyizinkulungwane ezingu-4.5 ngo-2027. Lokhu kwanda okulindelekile kubonisa izinga lokukhula elihlanganisiwe lonyaka (CAGR) lika-6.1% kusukela ngo-2021 kuya ku-2027.

Ukufunwa kwe imishini yokufafaza usimende kwenyukile ngenxa yokukhula kokugcizelela ekusebenzeni kahle nasekukhiqizeni ekwakhiweni, okuqhuba ukwamukelwa kwezinqubo zemishini nezizenzekelayo. Ukwengeza, le mishini inciphisa izindleko zabasebenzi ngokunciphisa umsebenzi wezandla kanye nokwenza lula inqubo yokuplasta, okuholela ekongeni kwezindleko kanye nokwenza ngcono inzuzo.

Izifunda ezinesidingo esikhulu semishini yokupulasitela usimende zifaka iNyakatho Melika, i-Europe, i-Asia-Pacific, iLatin America, iMiddle East kanye ne-Afrika.

Izinhlobo zemishini yokupulasitela usimende

1. Umshini wokuplasta wokushayela izikelemu

Ukushayela izikelemu umshini wokuplasta isebenzisa umshini wegiya lezikelemu ukuletha nokusebenzisa usimende owenziwe usimende. Ifaka i-screw shaft ezungezisayo ephushela impahla ye-plaster phambili, iqinisekisa ukugeleza okungaguquki. Lolu hlobo lomshini lwaziwa ngokwethembeka, ukusebenziseka kalula, kanye nekhono lokuphatha izinhlobo ezahlukene zokhonkolo. Inikeza ukulawula okunembile phezu kwesilinganiso sokugeleza kwe-plaster futhi ifanele amaphrojekthi amancane naphakathi nendawo.

2. Umshini wokuplasta wohlobo lwe-piston

Uhlobo lwe-piston imishini yokupulasitela sebenzisa isistimu eqhutshwa ngepiston ukupompa nokusebenzisa ukhonkolo. Injini yomshini ishayela ipiston, idala ingcindezi yokuphusha izinto ezisimende ngombhobho. Lolu hlobo lomshini luguquguquka kakhulu futhi lungakwazi ukuphatha izinhlobo ezahlukene ze-plaster, kuhlanganise nokhonkolo osekelwe usimende. Inikeza ukulawula okuhle kakhulu kokugeleza nokucindezela kwe-plaster, okuvumela ukusetshenziswa okunembile ezindaweni ezihlukahlukene.

Imishini yohlobo lwe-piston ithandwa ngokusebenza kahle kwayo, ukuqina, nokuvumelana nezimo ezidingweni zokuplasta ezihlukene.

3. Umshini wokulupha wephampu wesikulufa

Imishini yokupompa isikulufu isebenzisa indlela yesikulufu ukupompa nokuletha izinto ezisikiwe endaweni engaphezulu. Le mishini ifaka isikulufu esifana ne-auger esihambisa impahla ye-plaster ngesilinda, ekhiqiza ingcindezi yohlelo.

Iphampu yesikulufa imishini yokupulasitela zaziwa ngenqubo yazo yokuplasta ephumelelayo neqhubekayo. Zifanele imisebenzi yokukhonkoloza yangaphakathi nangaphandle futhi ngokuvamile zikhethwa kumaphrojekthi amakhulu ngenxa yamakhono azo aphezulu okukhipha.

4. Umshini wokuhlanganisa oqhubekayo wokuplasta

I-mixer eqhubekayo Imishini hlanganisa ukuxuba nokumpompa imisebenzi ye-plaster endaweni eyodwa. Banokunikezwa okuqhubekayo kwezinto ezihlanganisiwe ze-plaster, eziqeda isidingo sokuhlukanisa ukuxuba imishini. I-mixer ihlanganisa ngokuqhubekayo izingxenye ze-plaster, iqinisekisa ingxube ye-homogeneous.

Ukhonkolo oxubile ube usuhanjiswa ngqo ngepayipi noma ngepayipi ukuze ufakwe. Imishini eqhubekayo yokuhlanganisa i-mixer inikeza izinzuzo ezilula nezonga isikhathi. Futhi afaneleka kahle kumaphrojekthi adinga ukufakwa kukakhonkolo okuxubile okungaguquki.

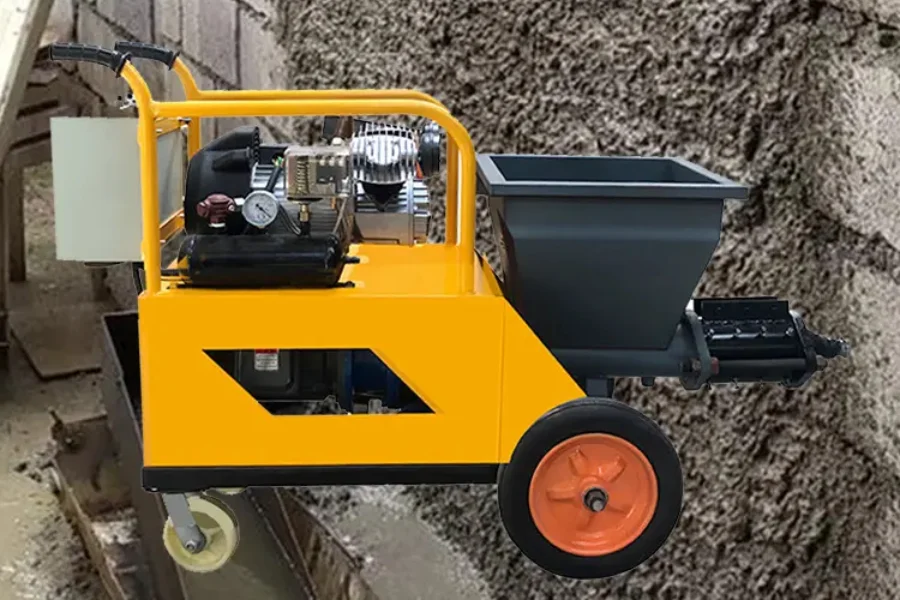

5. Futha umshini wokuplasta

Futha imishini yokufaka ukhonkolo sebenzisa umoya ocindezelweyo noma umfutho we-hydraulic ukuze wenze i-athomu bese ufafaza ukhonkolo endaweni engaphezulu. Zifaka isibhamu sesifutho noma umlomo wombhobho oqhubezela udaka endaweni eqondiwe.

Imishini yokufafaza iyasebenza kakhulu ukumboza izindawo ezinkulu ngokushesha futhi ifinyelele isiphetho esibushelelezi. Banikeza ukulawula okuhle kakhulu phezu kwephethini yesifutho futhi bavumela izilungiselelo ezilungisekayo ukuze zihlangabezane nezidingo ezahlukene zokupulasitela. Lolu hlobo lomshini luvame ukusetshenziselwa amaphrojekthi afana nokumbozwa odongeni, ukukhonkoloza kosilingi, kanye nokukhishwa kwangaphandle.

Izinto okufanele zicatshangelwe lapho uthenga imishini yokupulasitela usimende

1. Izinhlobo zemishini

Hlola ngokucophelela izinhlobo ezahlukene zemishini yokupulasitela usimende etholakala emakethe, njenge-worm drive, uhlobo lwe-piston, i-screw pump, i-continuous mixer, kanye nemishini yokupulasitela. Cabangela ngokucophelela izici, amakhono, nezindlela zokusetshenziswa zomshini ngamunye. Hlola ukuguquguquka kwazo kanye nokuvumelana nezimo ezihlukene zokuplasta. Ngokwenza ukuhlola okuphelele, unganquma ukuthi yimuphi umshini ofanelana kangcono nezidingo ezithile zokuplasta, uqinisekise ukusebenza kahle nangempumelelo.

I-2. Intengo

Kufanele ubheke ngale kwentengo yokuqala yokuthenga futhi ucabangele izinzuzo zesikhathi eside kanye nembuyiselo ekutshalweni kwezimali umshini wokuplasta usimende angahlinzeka. Linganisa izici ezifana nokuqina komshini, amandla okusebenza kwawo, nokonga kwezindleko okungaba khona ongakunikeza esikhathini esiphila kuwo. Intengo ejwayelekile yemishini yokupulasitela usimende ingahluka kuye ngohlobo, uhlobo, kanye nezici, isukela cishe ku-$2,000 kuya ku-$20,000.

I-3. Ukuqina

Njengoba uhlola imishini yokupulasitela usimende, hlaziya ngokucophelela ikhwalithi yabo yokwakha, izinto zokwakha, kanye nokuqina kukonke. Umshini oqinile uklanyelwe ukumelana nezimo ezinzima zezindawo zokwakha futhi ulethe imiphumela engaguquki esikhathini eside. Le mishini ivamise ukwakhiwa ukuze ihlale iminyaka engaba ngu-15, ihlinzeka ngesixazululo esithembekile sezidingo zokuplasta.

4. Amandla

Cabangela umthamo womshini mayelana namandla okubamba izinto zikakhonkolo, izinga lokumpompa, nendawo yokumboza. A umshini wokuplasta usimende ngomthamo owanele uzosebenza kahle ngaphandle kokuphazamiseka njalo noma isidingo sokugcwaliswa kabusha kwempahla. Ngokwesilinganiso, umthamo wokubamba imishini yokulameka izikelemu ungasukela kumalitha angama-30 kuye kwangama-70, kanti imishini yokuplasta yohlobo lwe-piston inamandla okubamba amalitha angama-40 kuye kwayikhulu.

Umthamo wokubamba wemishini yokupulasitela wepompo ungasukela cishe kumalitha angama-80 kuye kwangama-200, kuyilapho imishini yokuhlanganisa eqhubekayo yokupulasitela isukela kumalitha ayi-100 kuye kwangama-300.

5. Ijubane

Cabangela izinga lokupompa komshini kanye nokusebenza kahle komshini. Umshini osheshayo ungaba nomthelela omkhulu ekukhiqizweni, ovumela ukuqedwa kwamaphrojekthi ngempumelelo kakhudlwana futhi uhlangabezane neminqamulajuqu yephrojekthi. Isivinini esimaphakathi sale mishini singahluka kuye ngohlobo oluthile kanye nemodeli. Ngokuvamile, amazinga okumpompa angasukela kumalitha ayi-10 kuye kwangama-60 ngomzuzu. Kodwa-ke, kubalulekile ukuqaphela ukuthi isivinini esiqondile singahluka ngokusekelwe ezicini ezifana ne-viscosity yento ekhonjiwe, amandla nomklamo womshini, kanye nezindlela zokufaka isicelo.

6. Izinto ezisetshenziswayo

Different imishini yokupulasitela usimende aklanyelwe ukusebenza ngezinhlobo ezithile zokhonkolo, njengezikhonkwane ezenziwe usimende noma ezisekelwe ku-gypsum. Ukukhetha umshini ohambisana nezinto zikakhonkolo ohlose ukuzisebenzisa kuqinisekisa ukusebenza okuseqophelweni eliphezulu nokusebenzisa kahle. Iqinisekisa ukuthi umshini unezingxenye ezidingekayo kanye nezilungiselelo zokusingatha ukungaguquguquki okuqondile kanye nokuthungwa kwempahla ye-plaster, okuholela enqubweni yokukhonkolo ephumelelayo futhi ephumelelayo.

7. Ukusebenza kahle kwamandla

Beka phambili ukusebenza kahle kwamandla ngokukhetha imishini yokuplasta usimende esebenza kahle kakhulu kuyilapho usebenzisa amandla amancane. Isilinganiso samandla omshini noma ukucaciswa kuqinisekisa ukuthi usebenza kahle futhi kusiza ukunciphisa izindleko zamandla. Ngokukhetha umshini owonga amandla, ungonga ezindlekweni zokusebenza futhi ufake isandla ekwehliseni umthelela wemvelo ohambisana nokusetshenziswa kwamandla.

Isiphetho

Ukukhetha umshini wokuplasta usimende ofanele kubalulekile ukuze kube nemiphumela ephumelelayo nesezingeni eliphezulu yokuplasta. Izinto ezifana nohlobo lomshini, intengo, ukuqina, umthamo, isivinini, ukuhambisana, nokusebenza kahle kwamandla kufanele kubhekwe ngokucophelela ngesikhathi sokuthenga. Ukuhlola lezi zici kukusiza ukuthi ukhethe imishini ehlangabezana nezidingo zakho ezithile futhi kuthuthukise ukukhiqiza kanye nenzuzo. Ukuze uhlole izinhlobonhlobo zemishini yokupulasitela usimende, vakashela Cooig.com.