Ushicilelo lwe-3D yenye yezona teknoloji ziguqukayo ze-21st kwinkulungwane, kwaye ngokuthe ngcembe iyayiguqula indlela izinto ezidalwe ngayo, eziyilwe, nezizakhiwa ngayo. Ngoko ke akumangalisi ukuba ishishini loshicilelo lwe-3D lelinye lawona mashishini abalulekileyo okwenziwa abathengisi ukuba babukele.

Nangona kunjalo, abathengi abaninzi banokusokola ukuhlala besazi ngezinto ezintsha ezahlukeneyo kwitekhnoloji yoshicilelo ye-3D. Eli nqaku liza kuxubusha ezisixhenxe iteknoloji engundoqo ukwazi, kwaye unike iingcebiso ezibalulekileyo ngokukhetha inkqubo yoshicilelo ekunene.

Isiqulatho

Yintoni ushicilelo lwe-3D?

Isishwankathelo soshishino loshicilelo lwe-3D

Iintlobo ezisi-7 zetekhnoloji yoshicilelo lwe-3D

Indlela yokukhetha inkqubo yoshicilelo ye-3D echanekileyo

isiphelo

Yintoni ushicilelo lwe-3D?

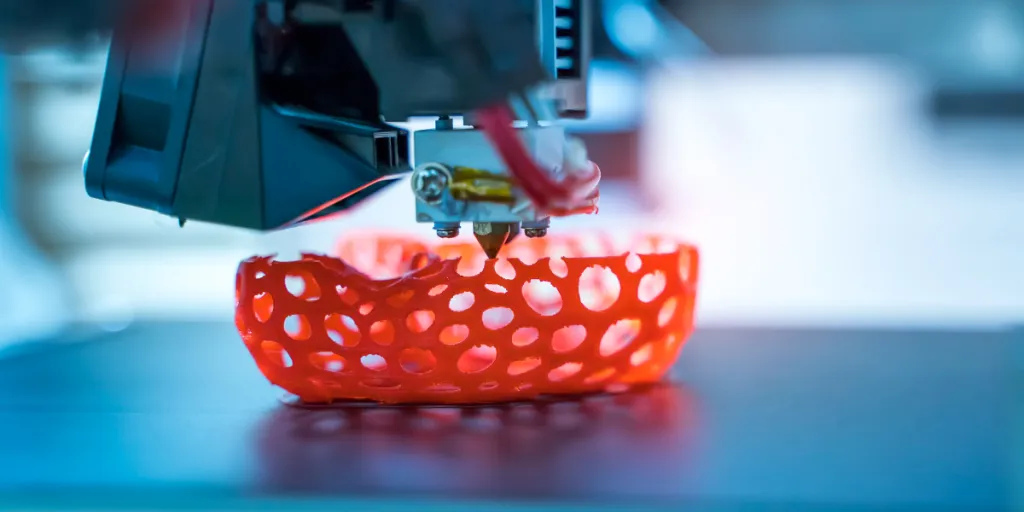

Ushicilelo lwe-3D yinxalenye yenkqubo eyaziwa njengemveliso yokongeza, apho into yenziwa ngokudibanisa umaleko wezinto ngokwemaleko. Ngelixa le nkqubo isetyenziswa kwimveliso enkulu ukwenza iinxalenye zemoto okanye amacandelo enjini yejeet, inokusetyenziswa ekhaya okanye kusetyenziso lweshishini kusetyenziswa abancinci. Abashicileli be-3D.

Inyathelo lokuqala kushicilelo lwe-3D libandakanya ukudala umzobo wento eza kushicilelwa. Nje ukuba umsebenzisi abe noyilo lwe-3D, bayayithumela kumshicileli ofumana idatha, itsale imathiriyeli ngetyhubhu, iyinyibilikise, kwaye iyifake kwipleyiti apho iphole khona ngoko nangoko. Into ye-3D yenziwe ngokubeka, njengoko umshicileli uya kongeza umaleko omnye wezinto ngexesha de kuvele isakhiwo esipheleleyo.

Isishwankathelo soshishino loshicilelo lwe-3D

Imarike yoshicilelo ye-3D ifumana ukukhula okuzinzile. Ngo-2023, imakethi yehlabathi ifikelele kuqingqo lwexabiso I-US $ 20.67 yezigidigidi – inani ekulindeleke ukuba linyuke liye kutsho kwi-US$91.8 billion ngo-2032.

Ukuqhuma kweteknoloji yedijithali kukuchaphazela ukunyuka kweshishini lokushicilela i-3D, efanelekileyo kwimveliso yanamhlanje. Amazwe amaninzi sele amkele ushicilelo lwe-3D, kunye ne-United States ephuma njengeyona nkcitho iphezulu malunga nokuthenga iiprinta ze-3D ngo-2023, ibalwa ngaphezulu kwe-34% yesabelo semarike. Njengoko imfuno yoshicilelo lwe-3D iqhubeka ikhula, amashishini afumana izixhobo ezifanelekileyo zoshicilelo lwe-3D alungele ukuxhamla kwimarike enkulu.

Iintlobo ezisi-7 zetekhnoloji yoshicilelo lwe-3D

Kukho iintlobo ezininzi zetekhnoloji yoshicilelo ye-3D esetyenziswa kwihlabathi jikelele. Ukuqonda ezi ntlobo kunokunceda abathengisi benze izigqibo ezinolwazi xa begcina iimveliso kunye nokuphucula ukhetho lwemveliso ngokusekelwe kwimfuno. Ziquka oku kulandelayo:

1. I-Stereolithography (SLA)

I-Stereolithography, okanye i-SLA, yinkqubo yoshicilelo ye-3D esebenzisa i-laser ukunyanga i-resin engamanzi kwiplastiki eqinile. Ujonge phantsi okanye ujike istiriyo yeyona nkqubo ixhaphakileyo ye-SLA.

Ngokuxhomekeke kumatshini, i-resin igalelwa kwitanki ngumsebenzisi okanye ikhutshwe ngokuzenzekelayo kwi-cartridge.

Ekuqaleni koshicilelo, iqonga elakhiweyo lithotywa kwi-resin, lishiya kuphela umaleko omncinci wolwelo phakathi kwendawo yokwakha kunye nezantsi kwetanki.

Iglasi ecacileyo emazantsi etanki ye-resin ivumela i-galvanometers ukuba iqhube i-laser ye-UV, i-sketching i-cross-section ye-3D model kunye nokuzikhethela ukuqina kwezinto. Ushicilelo lwakhiwe ngokwemigangatho elandelelanayo, nganye inobunzima obungaphantsi kwe-100 microns.

Emva kokuba umaleko ugqityiwe, iqonga liyathotywa kwakhona, kwaye inxalenye ixotyulwa ukusuka ezantsi kwetanki ukuvumela intlaka entsha ukuba iphume ngaphantsi.

Ekuqaleni yaphuhliswa kwi-80s, i-SLA yayivalelwe koomatshini abakhulu bemizi-mveliso kude kube kutshanje. Namhlanje, i-desktop lithography ibonelela ngokufikelelekayo, ushicilelo oluphezulu lwe-3D olungena lula kwindawo yokusebenza yomsebenzisi.

I-SLA ivumela ukusebenzisa uluhlu olubanzi lwezinto ezineempawu ezahlukeneyo zomzimba. Nokuba yinjineli, umyili wemveliso, umkroli, ijuweler, okanye ugqirha wamazinyo, kukho imathiriyeli yokusetyenziswa kwabo.

2. Ukulungiswa kokukhanya kwedijithali (DLP)

In ukusetyenzwa kokukhanya kwedijithali okanye i-DLP, eyona nkqubo yokunyanga nokuvelisa into ye-3D iyafana ne-SLA 3D yoshicilelo, ngaphandle kokutenxa enye. I-Stereolithography isebenzisa i-laser ukwenza i-3D replica yento kumphezulu wetanki, ukwenza umaleko ngaphezulu kwenye.

Kwimeko yokulungiswa kokukhanya kwedijithali, i-laser ithathelwa indawo yesibane se-arc okanye umthombo wokukhanya. Ukukhanya kuqikelelwa ngokohlobo lwemilo enqwenelekayo kumphezulu wepolymer engamanzi, kwaye ipholima yolwelo ethile iba lukhuni ngokulula, iyenze ukuba idle ixesha elincinci kunelaser ukwenza imilo. Isiphumo yinkqubo yoshicilelo ye-3D ekhawulezayo kune-SLA.

Ukusetyenzwa kokukhanya kwedijithali kusebenzisa izixhobo ezahlukeneyo ezifana nenayiloni, i-ABS, kunye ne-thermoplastics. Ngoko ke, iyaguquguquka. Ikwavelisa iimilo ezahlukeneyo isebenzisa ushicilelo olusuka ezantsi ukuya phezulu kwisisombululo esiphezulu.

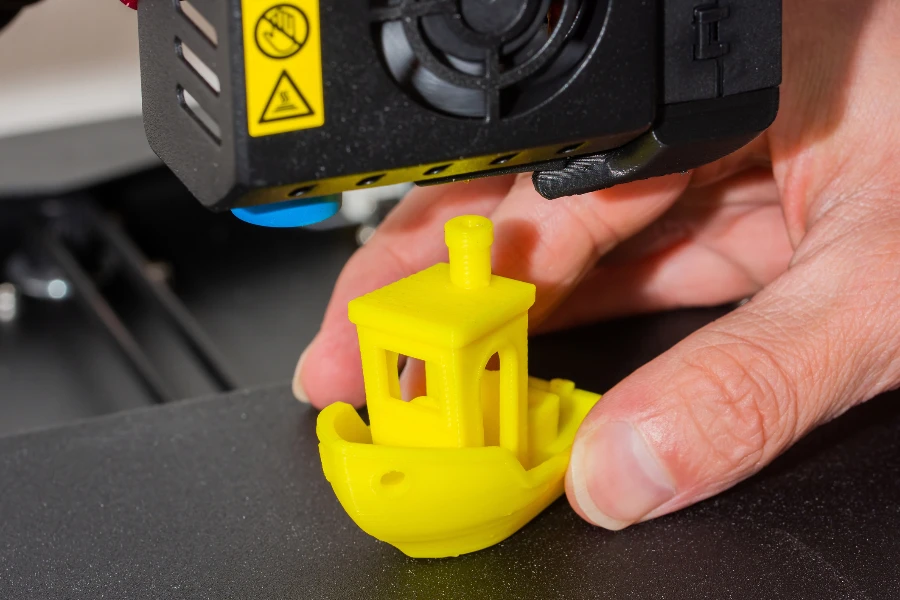

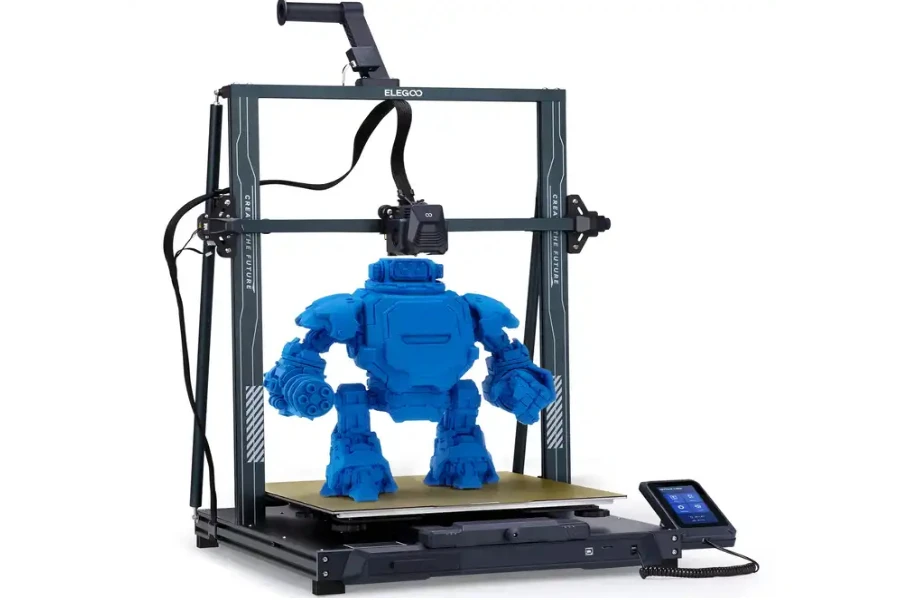

3. Umfuziselo wodipo oludityanisiweyo (FDM)

Le nkqubo yoshicilelo yomaleko ye-3D isebenzisa izixhobo ze-thermoplastic zokuvelisa ukuvelisa zombini iiprototype kunye neendawo zokusetyenziswa kokuphela.

Itekhnoloji iyaziwa ngokuvelisa iinkcukacha zeempawu ngokuchanekileyo kwaye inomlinganiselo obalaseleyo wamandla ukuya kubunzima. Ilungele iimodeli zengqikelelo, iiprototypes ezisebenzayo, izixhobo zokuvelisa, kunye nenxalenye yokusetyenziswa komthamo ophantsi.

The Inkqubo yeFDM iqala "ngokusika" idatha ye-3D CAD kwiileya. Idatha ke idluliselwe kumatshini owakha umaleko wenxalenye ngomaleko kwiqonga lokwakha.

I-spools emincinci efana nentambo ye-thermoplastics kunye nezinto ezixhasayo zisetyenziselwa ukudala inxalenye nganye enqamlezayo. Njengompu weglu onyibilikayo oshushu, izinto ezingabotshwanga zikhutshwa kancinane ngemilomo eshushu kabini. Ngokuchaneka, imilomo ibeka phantsi zombini inkxaso kunye nemathiriyeli yoshicilelo ye-3D kumaleko angaphambili.

Umbhobho we-extrusion uyaqhubeka nokuhamba kwinqwelomoya ye-XY ethe tye ngelixa iqonga lokwakha lisihla, lisenza umaleko wenxalenye umaleko. Umsebenzisi ususa inxalenye egqityiweyo kwiqonga lokwakha kwaye ahlambulule izinto ezixhasayo.

Amalungu e-RAW FDM anemigca ebonakalayo. Iinketho ezininzi zokugqiba njengokusantiya ngesandla, ukudityaniswa, okanye ipeyinti yokuthambisa inokusetyenziswa ukwenza iziqwenga ezigudileyo, nezingaphezulu.

Ngelixa iinxalenye ze-FDM zakhiwe nge-thermoplastics efana ne-ABS, i-polycarbonate, kunye ne-ultem, zombini ziyasebenza kwaye zihlala ziqinile.

4. Ukukhetha i-laser sintering (SLS)

Ushicilelo lwe-SLS lushicilelo olusekwe kwi-laser powder esebenzisa umgubo njengento ekrwada endaweni yefilament okanye intlaka. Inkqubo yoshicilelo iqala ngokunciphisa i-powder reservoir kwaye igcwalise ngomgubo we-thermoplastic, ngokuqhelekileyo inayiloni.

Iinqununu ezenza i-powder zijikeleze, kunye nobubanzi obungaphantsi kwama-microns angama-100 kunye nokuthungwa okucolile. Oku kuvumela ukuba i-powder isasazeke kwinqanaba elincinci, elincinci, elibalulekileyo kwimpumelelo yoshicilelo lwe-SLS.

Ngaphambi kokuqala ukuprinta, umgubo ufudunyezwa nje ngaphantsi kweqondo lokushisa lokunyibilika ngokusebenzisa iikhoyili zokufudumeza kwaye, kwezinye iimeko, izibane ze-infrared. I-powder igcinwe kule bushushu kulo lonke ushicilelo ukuze kube lula ukuba i-laser inyibilike umgubo ngenxa yokuba inani elincinci lamandla liya kufuneka. Ikwathintela inxalenye eprintiweyo ukuba ingajiki ngenxa yeqondo lobushushu.

I-spreader ye-powder efana ne-blade okanye i-roller idala i-uniform layer kwi-platform yokwakha; emva koko, i-laser ifudumeza ngokukhethiweyo imimandla yendawo yokwakha ukunyibilikisa umgubo kwijometri echaziweyo. Le nxalenye iyaphindwa, kwaye iqhekeza ngalinye liba lide emva komaleko ngamnye.

Kufuneka kucace ukuba kukho iziphene okanye izinto zakudala kwipowder, ezi ziphene ziya kuguqulela ngokuthe ngqo kwinxalenye, kubangele iimpawu ezimbi zoomatshini okanye ukungaphumeleli kokushicilela. Yiyo loo nto iileya ezigudileyo, ezifanayo zibalulekile.

Xa konke kuhamba kakuhle, umgubo ongafakwanga uvala ngokupheleleyo inxalenye eprintiweyo. Oku kuthetha ukuba imathiriyeli yenkxaso ayiyomfuneko kushicilelo lwe-SLS; nayiphi na ijometri inokuprintwa. Isithintelo kuphela kufuneka kubekho indawo eyaneleyo yokususa umgubo okhululekileyo emva kokushicilela.

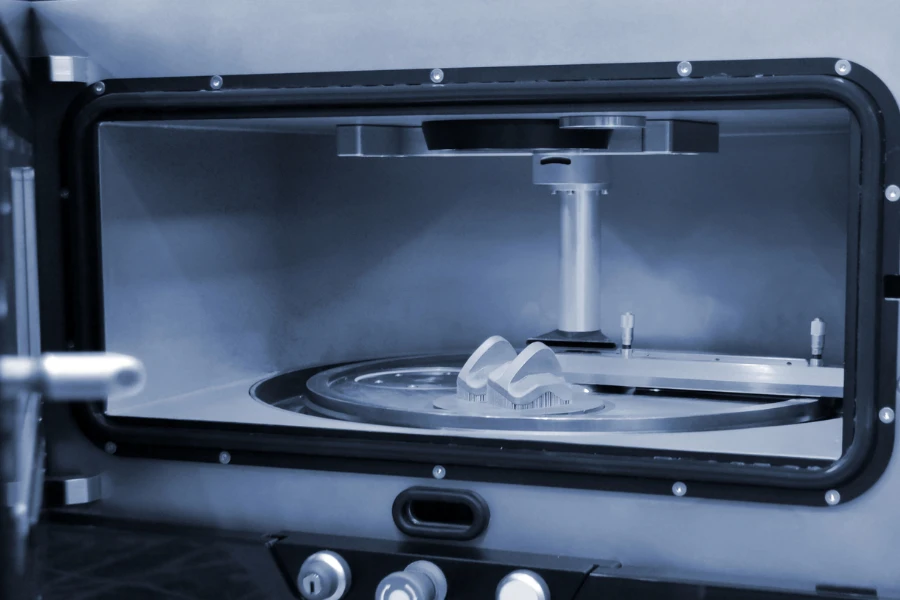

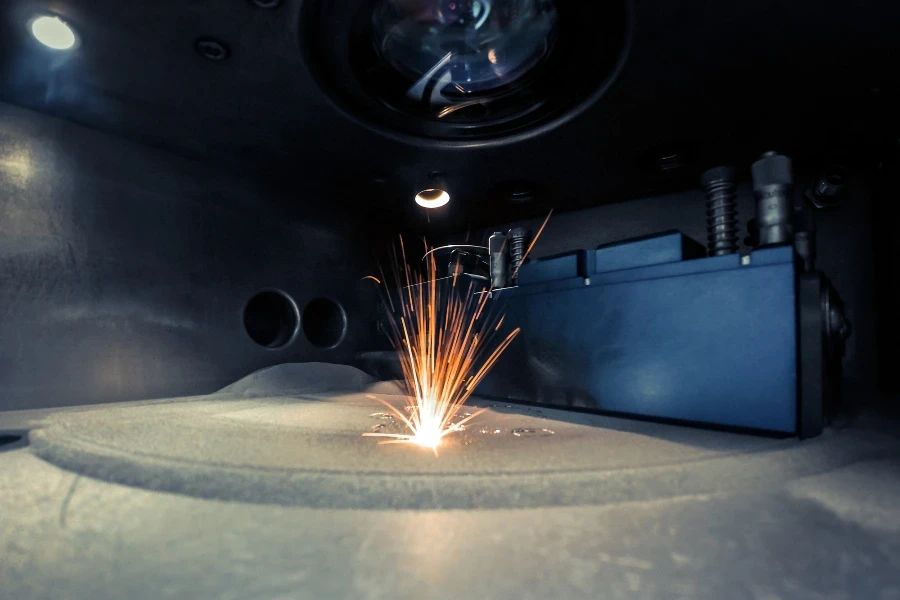

5. Ukunyibilika kwelaser ekhethiweyo (SLM)

The Ukunyibilika kwe-laser okukhethiweyo Inkqubo isebenzisa imathiriyeli engumgubo wesinyithi ukwakha umaleko wento ngokomaleko. Isetyenziselwa ukwenza izinto kusetyenziswa iintsimbi ezahlukeneyo, ezidla ngokuba noxinzelelo oluphezulu. Le teknoloji yoshicilelo ye-3D isebenzisa i-laser ukunyibilikisa umgubo wesinyithi, opholisa kwaye uqinise.

Umjikelo welaser ngamnye uvelisa isilayi esitsha sento edalwayo, kwaye ke iqonga lomsebenzi liye lithotywe ngokuthe ngqo ubukhulu becala elinye njengoko i-scraper isasaza umgubo. Isinyithi esinyibilikisiweyo siqina, kwaye inkqubo iphinda iphindwe.

I-laser idibanisa amaleko amadala kunye namatsha de iprototype igqitywe. Icandelo ngalinye lidityaniswe kwiqonga lomsebenzi kunye nenkxaso edibeneyo emva kokuba icandelo lisusiwe.

Into egqityiweyo iyasuswa kumgubo ongasetyenziswanga kwakhona kwaye ikhululwe kumgubo ogqithisileyo, okukhokelela ekuchanekeni okuchanekileyo kweemveliso ezenziweyo.

Ukunyibilika kwelaser okukhethiweyo kungqina ukubaluleka kwayo xa izinto ezintsonkothileyo kufuneka ziveliswe ngokukhawuleza. Ikwavumela ukuveliswa kweemveliso ezintsonkothileyo kunye nezinto ezisebenzayo ezidibeneyo ezifana nokupholisa okuhambelanayo.

6. Ukunyibilika komqa we-elektroniki (EBM)

Ukunyibilika komqadi we-elektroniki yinkqubo yokwenziwa kwesinyithi esongezelelweyo esinendawo yokuqalisa ibhedi yomgubo wentsimbi edityanisiweyo umaleko wokwakha inxalenye yentsimbi eyomeleleyo usebenzisa umqadi we-electron.

Xa kuthelekiswa neendlela eziqhelekileyo zokudityaniswa kwebhedi yomgubo welaser njenge-SLS kunye ne-SLM, yinkqubo yamandla aphezulu, kungoko kusetyenziswa umqa we-electron.

Ukunyibilika komqadi we-elektroniki ngokuqhelekileyo kwenzeka ngaphakathi kumatshini phantsi kwevacuum kumaqondo obushushu aphezulu. Umsebenzisi uqala ngokusasaza umaleko womgubo wentsimbi kuyo yonke indawo yokwakha kunye nokufudumeza wonke loo mgubo. Emva koko, i-electron beam iyayidibanisa ngokunyibilikisa iindawo ezifunekayo ukwakha into.

Inkqubo iphinda iphindwe ukuze ekugqibeleni igqitywe ngebhloko ye-semi-solid okanye ikhekhe le powder equkethe izinto ezixutywe ngaphambili. Isinyathelo esilandelayo sidinga ukuthotywa kwamandla kwibhloko kwaye emva koko uqhubeke nokuhamba komsebenzi.

Enye yeenzuzo ze-EBM kukuba umthombo wamandla ophezulu wenza kube lula ukusebenzisa i-diameter enkulu umgubo wentsimbi, ekwalula ukusebenza nayo. Kananjalo ayinayo nayiphi na ingozi yokuphefumla xa isebenza ngomgubo ocolekileyo. Ngoko ke, nge-EBM, ukusebenza kunye nomgubo kunye nokujikeleza ngaphandle kwezixhobo ezikhethekileyo zokhuseleko kunokwenzeka.

Enye inzuzo yokunyibilika komqadi we-elektroniki kukuba kwenzeka kumaqondo obushushu aphezulu kunomxube webhedi yomgubo welaser. Oku kuguqulela kulawulo olungcono kuxinzelelo lwe-thermal, ukungqubana okuncinci kunye nokugqwetheka, kunye nokuchaneka okungcono komgangatho.

Ukunyibilika komqadi we-elektroniki ngokuqhelekileyo kusetyenziselwa ukwenza ukufakelwa kwezonyango, nangona sele kusetyenziswe kwi-aerospace kunye nobunjineli beemoto.

7. Ukwenziwa kwento elayitiweyo (LOM)

Enye iteknoloji yoshicilelo lwe-3D yi ukwenziwa kwezinto ezilaminethiweyo. Ukwenziwa kwento elayitiweyo, okanye i-LOM, yinkqubo ekhawulezayo yokwenziwa kweprototyping apho amaphepha agqunyiweyo, iplastiki, okanye iileya zentsimbi ezilaminethiweyo zidityaniswe ngempumelelo kwaye zisikwe ukumila ngesixhobo sokusika okanye i-laser cutter.

Uluhlu ngalunye lwenkqubo yokwakha luqulethe i-cross-sections enye yamacandelo amaninzi. Phambi kokuba inkqubo iqale, umfanekiso osuka kwi-CAD-derived STL ifayile ifakwa kumshicileli. I-software yenkqubo ye-LOM ibala kwaye ilawula imisebenzi yokuqhawula, ngelixa i-lamination kunye nokuqhelaniswa kwezinto kwenzeka ngesandla.

Kwinkqubo yokwakha, inkqubo idala i-cross-section ye-3D model, ilinganisa ubude obuchanekileyo bomzekelo, kwaye inqumle indiza enqamlekileyo ngokufanelekileyo. Isoftware ke inemifanekiso enqamlezileyo kunye nomjikelezo wemodeli.

Umqadi omkhulu usika ubukhulu bomaleko omnye wezinto ngexesha, kwaye emva kokuba umjikelezo utshisiwe, umda wemodeli uyakhululwa kwiphepha eliseleyo.

Iqonga elinenqwaba yeeleya ezenziwe ngaphambili liyehla, kunye necandelo elitsha lenkqubela phambili yezinto.

Iqonga liyenyuka, kwaye i-roller efudumeleyo ibeka izinto eziphathekayo kwi-stack kunye nentshukumo enye yokubuyisela, ukuyibophelela kuluhlu lwangaphambili. Emva koko, i-encoder ethe nkqo ilinganisa ubude bengqumba kwaye ibuyisela umphakamo omtsha ukusika. Olu landelelwano luqhubeka de zonke iileya zakhiwe.

Ukucutshungulwa kwezinto kulandela emva kokuba izinto zenziwe ngokupheleleyo, ezibandakanya ukwahlula inxalenye ye-laminated kwi-block LOM. Emva kokwahlula, loo nto inokugatywa, ikhazimliswe, okanye ipeyintwe njengoko ifunwa.

Indlela yokukhetha inkqubo yoshicilelo ye-3D echanekileyo

Amashishini angakwazi ukukhetha okulungileyo 3D yoshicilelo indlela kuphela ukuba baqwalasela imiba ethile ephambili. Nazi izinto ezintathu eziphambili zokubeka phambili ngaphambi kokutyala imali kwitekhnoloji ethile.

1. Imveliso okanye inkqubo yokukwazi ukwenza

Okokuqala, xa ukhetha itekhnoloji yoshicilelo ye-3D, yehla ekusebenzeni kwenkqubo yokwenza imveliso. Iimpawu ezibonakalayo zento eyenziweyo zinokunceda abasebenzisi banciphise indlela yokushicilela. Oku kubandakanya ubukhulu obunqwenelekayo bemveliso, ukuchaneka, ubungakanani, okanye ulwakhiwo lwenkxaso.

Umzekelo, ubuncinci bodonga lokushicilela kwi-SLA yi-0.6mm, ngelixa ukukhanya kwedijithali kunokuhlala ukuya kuthi ga kwi-0.2mm. Isiphumo sento eprintiweyo sesona sichanekileyo ngokudityaniswa kwe-fused, ngelixa i-SLA iyeyona ichanekileyo kwaye inesisombululo esiphezulu.

Ngelixa i-SLS okanye i-SLA igqwesileyo kwiimfuno ezininzi zoshicilelo lwe-3D, uyilo olunzima ngakumbi olufuna ukuphathwa kweengcali lunokufezekiswa nge-FDM, i-EBM, okanye i-LOM yokushicilela.

2. Iimpawu okanye ukusebenza kwamacandelo esiphelo

Enye indlela yokukhetha inkqubo yoshicilelo ye-3D efanelekileyo kukuqwalasela ukusebenza kwemveliso yokugqibela. Oku kubandakanya ukujonga ukungachaphazeleki kwiimeko zokusingqongileyo, ukuba bhetyebhetye, ukuqina, kunye neminye imiba ebonakalayo efana nokumelana neekhemikhali kunye nobushushu, ukhuseleko lwendalo, kwaye ukuba iyatyiwa.

Ukubonakaliswa kokufuma okanye ukukhanya kwelanga kunokuchaphazela umgangatho weemveliso; ngenxa yoko, ukuxhathisa ubushushu kunye nokufuma akuqinisekiswanga i-resin-based iinkqubo ezifana SLA okanye DLP. Ke ngoko, abasebenzisi banokujonga iindlela ezisekwe kwi-powder infusion njenge-EBM, i-SLM, okanye itekhnoloji yokuprinta ye-LOM. Ukongeza, izinto eziprintwa kusetyenziswa obu buchwepheshe zineempawu zekhemikhali ezinamandla kakhulu.

Oku kuthetha ukuba i-SLA kunye ne-DLP ziya kuhambelana nokuprintwa kwezinto ezingayi kubonakaliswa kwizinto ezirhabaxa zangaphandle, ngelixa iindlela ze-electronic beam ezinyibilikayo ezikhethiweyo ze-laser sintering zisebenza kakuhle ekushicileleni izixhobo ze-industrial-grade.

3. Izinto eziphathekayo kunye nokugqiba

Okokugqibela, amashishini kufuneka agxininise uhlobo lwemathiriyeli abaza kuyisebenzisa ukuvelisa into kunye nokugqiba abakulindeleyo kushicilelo. Izinto eziqhelekileyo ezisetyenziselwa ushicilelo lwe-3D zibandakanya ifilim, powder, kunye neresin, apho ezi mathiriyeli ziphinda zihlelwe ngokweepholima okanye iiplastiki, isinyithi, iiseramikhi, kunye zizihlanganisi.

Iiplastiki zikwahlulahlulwe kwi-thermoplastics kunye ne-thermosets. I-SLS kunye ne-FDM zifaneleke kakhulu kwi-thermoplastics, ngelixa iteknoloji yokushicilela i-thermosets i-stereolithography kunye ne-Digital Light Processing (DLP).

Izixhobo zentsimbi zinezona mpawu zinamandla kwaye zilungele i-aerospace, iimoto, kunye nezicelo zonyango. Uhlobo lwemathiriyeli lubalulekile xa kusenziwa iindawo ezomeleleyo ezinje ngeehenjisi zocango okanye ezinye iindawo zentsimbi ezisetyenziselwa ukukhanya. I-SLM, i-LOM, kunye neenkqubo ze-EBM zibonelela ngezisombululo zokushicilela kwiimfuno ezinjalo.

Ngeli xesha, obu buchwephesha bokuprinta bohlukeneyo bukwaneziphelo ezahlukeneyo. Umzekelo, abo bafuna ukugqitywa okucwebekileyo okanye okucwebezelayo banokukhetha ubuchule be-SLA kunye ne-FDM. I-SLA kunye ne-DLP iya kwenza ukugqitywa okucacileyo. Idiyidi edayiweyo okanye i-matte inokwenzeka xa usebenzisa i-laser sintering ekhethiweyo.

isiphelo

Ekugqibeleni, kukho iitekhnoloji ezahlukeneyo zokuprinta ze-3D, kwaye ukukhetha okulungileyo kuvela kwiimfuno zomsebenzisi. Ezinye izinto, ezifana nemathiriyeli kunye nokusebenza, nazo ziya kumisela uhlobo lwetekhnoloji enokusetyenziswa. Abasebenzisi abalungele ukuqalisa uhambo oluyimpumelelo loshicilelo lwe-3D banokuphonononga uluhlu lwabashicileli abathembekileyo be-3D Cooig.com.