Abavelisi bahlala bedinga iinkqubo ezilungiselelwe kakhulu nezithembekileyo kwiimveliso zabo. Itekhnoloji yeLaser iqhubele phambili ukubonelela nge-laser ye-welding ephezulu yokusebenza, ukukrola, kunye noomatshini bokusika abanciphisa ixesha lokuvelisa ekuphenduleni iimfuno zeshishini lehlabathi.

Eli nqaku liza kuqala lixoxe ngemakethi yomatshini welaser oguqukayo ngaphambi kokuchaza iintlobo ezahlukeneyo zoomatshini boshishino lwelaser kunye neendlela ezixhaphakileyo kuMzantsi-mpuma weAsia.

Isiqulatho

Amagqabantshintshi emarike yomatshini welaser ngo-2023

Iintlobo zoomatshini belaser boshishino

Iindlela eziphambili zomatshini welaser kuMzantsi-mpuma weAsia

Jonga ezi ndlela

Amagqabantshintshi emarike yomatshini welaser ngo-2023

Imakethi yoomatshini bokusika i-laser yayixabisa i-USD 6,832.8 yeebhiliyoni ngo-2022, kwaye ukusuka ngo-2023 ukuya ku-2030, inokwanda ngesantya sokukhula sonyaka (CAGR) se-5.5%. Imfuno ekhulayo yokusetyenziswa kokuphela komzi-mveliso kunye nokunyuka kwe-automation kwicandelo lezemveliso kulindeleke ukuba konyuse imfuno yokusika i-laser ngexesha loqikelelo, ukuxhasa ukwandiswa kwemarike yomatshini wokusika i-laser.

Amashishini okugqibela afana ne-HVAC, iimoto, kunye ne-elektroniki zisebenzisa kakhulu ezi zixhobo ukuvelisa iimpahla ezikumgangatho ophezulu ngokufanelekileyo. Ngenxa yokuchaneka kwezixhobo kunye nokufana kweziphumo zabo, abavelisi batyala imali kwi-automation ye ukusikwa kwelasi, ukwandisa ukukhula kweemarike.

Ukuvela kwe-fiber laser cutting kuya kuxhasa ngakumbi ukwandiswa kwemarike. Imisebenzi emininzi yokulungisa i-macro efuna ukuchaneka kwenqanaba lemilimitha, njengokusika kunye nokuwelda iintsimbi zamashishini, kubandakanya ukusebenzisa izixhobo zokusika i-fiber laser. Amandla emarike okwenziwa kwe-macro-processing abaluleke kakhulu kune-micro-processing ngenxa yemfuno ephezulu yezixhobo zelaser.

Imiqobo ebalulekileyo ekwandiseni imarike ibandakanya amaxabiso aphezulu, ukusetyenziswa kwamandla aphezulu, ixabiso eliphezulu leendawo zoomatshini kunye nokugcinwa kwazo, kunye nokukhutshwa kweerhasi ezinetyhefu njengerhasi yephosgene.

Iintlobo zoomatshini belaser boshishino

Oomatshini bokuwelda ngeLaser

Uhlobo olunye lwe izixhobo zokusebenza laser esetyenziselwa ukuwelda kunye nokusika isinyithi yilaser welder. Lo msebenzi wokusebenzela ufumana inaliti yamandla kumqadi welaser, onyibilikayo kwaye womelele ngokukhawuleza kwaye unciphise ukugqwetheka emva kokuwelda.

IiLaser zinoxinzelelo olukhulu lwamandla. Ngamanye amazwi, banokugxininisa bonke ubushushu babo ngqo kumthungo, baphucule imeko yezinto ezibajikelezileyo, xa kuthelekiswa noomatshini abaqhelekileyo bokuwelda.

Ukuwelda kweLaser icoceke ngendlela emangalisayo kwaye ayifuni kusila okanye ukucocwa emva kokulungiswa. Ezi welds zobuhle zikwanika iimveliso zabasebenzisi bokuphela inkangeleko yeprimiyamu kwaye zenze imbonakalo yokuqala eyonwabisayo.

I-Laser welding imalunga namaxesha amahlanu ukuya kwalishumi ngokukhawuleza kuneendlela zendabuko zokuwelda, oku kuthetha ukuba ixesha lokuguqula ngokukhawuleza kunye nokwandisa imveliso, ngaphandle kokuncitshiswa kwe-post-processing.

Ukuguquguquka kwalo matshini kukwesibini. Nantoni na nayo yonke into inokudityaniswa kusetyenziswa ukuseta kwelaser eyahlukeneyo, kubandakanywa iipleyiti zentsimbi ezinzima kwishishini lokuthumela, iintsimbi ezixabisekileyo zobucwebe, iintsimbi ezahlukeneyo ezifana ne-aluminium kunye nentsimbi, okanye unxibelelwano lobhedu lweebhetri zemoto yombane. Nkqu neeseramics zokuwelda, udidi lwemathiriyeli eyaziwa ngokuba nzima ukuweldiswa, lubone impumelelo ethile yovavanyo.

Zonke ezi zibonelelo zinexabiso nangona. Ukuseta iLaser kunokubiza kabini okanye kathathu ngaphezulu kweenkqubo eziqhelekileyo. Nangona kunjalo, ixabiso ngeyunithi nganye liyancipha, kwaye utyalo-mali luvelisa izabelo ukuba umthamo uphezulu.

The imarike koomatshini bokuwelda ngelaser baya kukhula kwi-CAGR ye-4.73% phakathi kuka-2021 no-2025, bafikelele kwi-USD 373.97 yezigidi ekupheleni kwexesha eliqikelelweyo ngokwemigaqo yosetyenziso olwahlukeneyo.

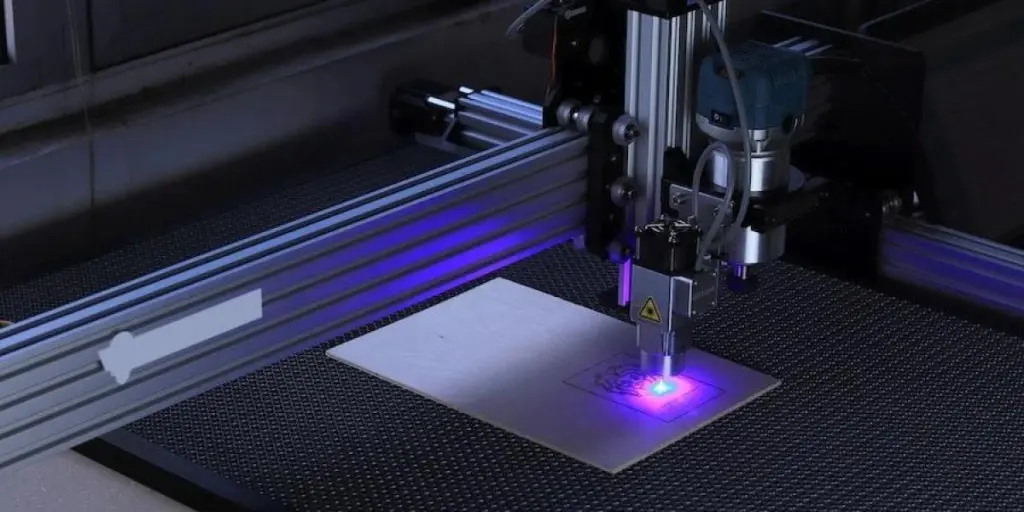

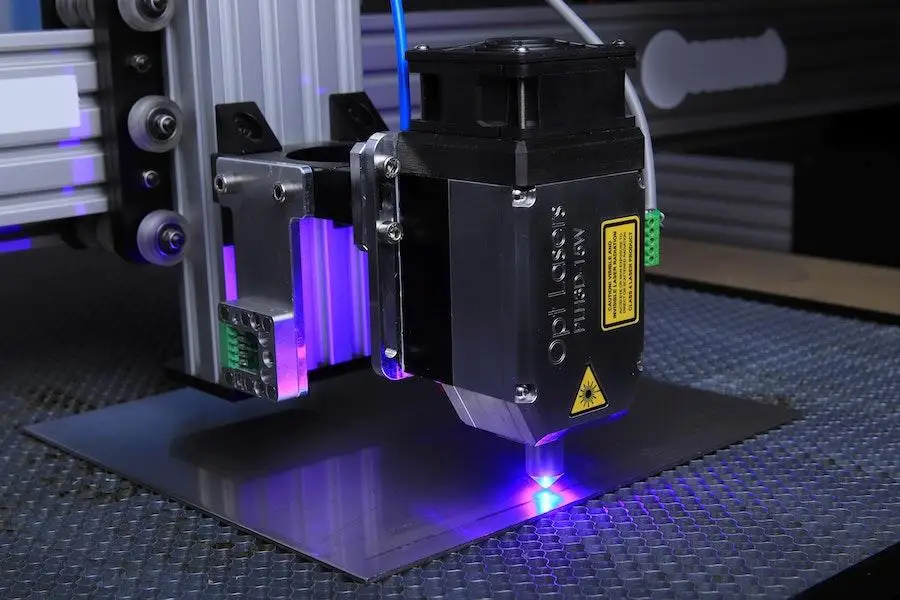

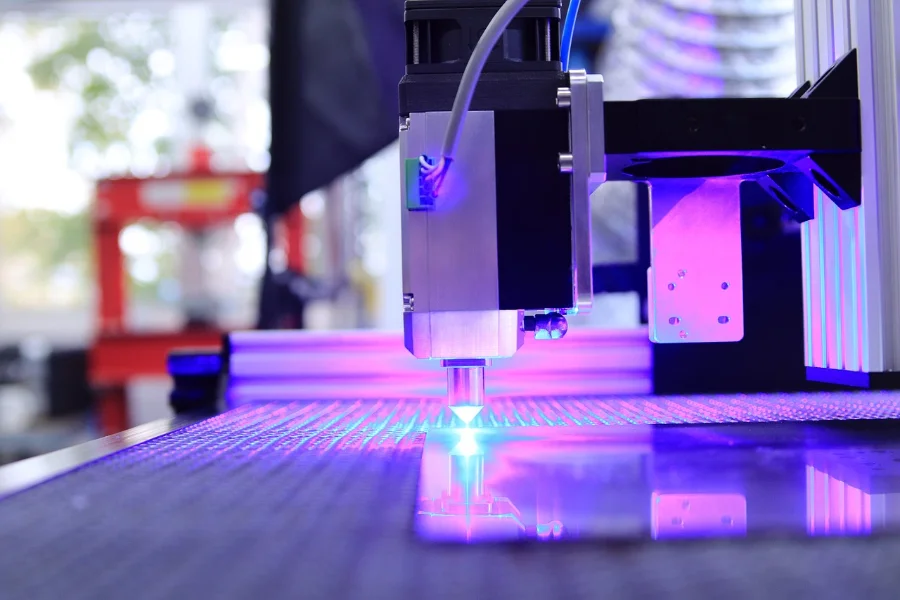

Oomatshini bokukrola ngeLaser

Iinjineli ngoku zinokuvelisa oonobumba, amanani, okanye imifanekiso ngaphandle kokubeka esichengeni amalungu ayisebenzisayo laser ngentlabo. Le ndlela isebenzisa ukukhanya kwe-laser ekugxilwe kuyo ukudala amanqaku angenakonakala kwaye kulula ukufunda kunokuba afake umphezulu okanye ukuhambisa i-inki ngesixhobo somzimba.

Ezi zixhobo asikwe ngokuzenzekelayo aze akrole izinto ezahlukahlukeneyo, njengentsimbi, umthi, iglasi, neplastiki ngokuchaneka.

Ayisebenzisi izinto ezityiwayo kwaye ngoko iluhlaza, ayibizi, kwaye inamandla ombane xa ithelekiswa nezinto ezisetyenziswayo ezifana nee-inki kunye neekhemikhali ezisetyenziswa kwezinye iinkqubo zokumakisha, ezixabisa kakhulu kwaye zinefuthe elibi kwindalo esingqongileyo. Ukumakishwa kweLaser, endaweni yeelebhile, kubonelela ngokuchongwa okusisigxina kwamalungu kwaye ayifuni ukusetyenziswa okuphindaphindiweyo.

Ubume bokungadibanisi bokumakishwa kwelaser buqinisekisa indawo ecocekileyo, engcolisekileyo yokusetyenzwa. Inkqubo yomonakalo-free kuphela kancinane okanye ayigqobhozi imathiriyeli, ngokungafaniyo neenkqubo zoshicilelo eziya kutshisa izinto phantsi ngokumakisha.

Ukuprinta iLasera ikwanceda abavelisi bathobele imithetho ephakamisa umgangatho, ukulandeleka, kunye neminye imigangatho yokhuseleko, efunwa yimibutho yomanyano, ishishini leemoto, amayeza, inqwelomoya, kunye namanye amashishini anovakalelo.

Ngokoqikelelo lomhlalutyi wemarike, imarike yokukrola i-laser kulindeleke ukuba yande kwi-CAGR ye-4.93% ukusuka ngo-2017 ukuya ku-2030.

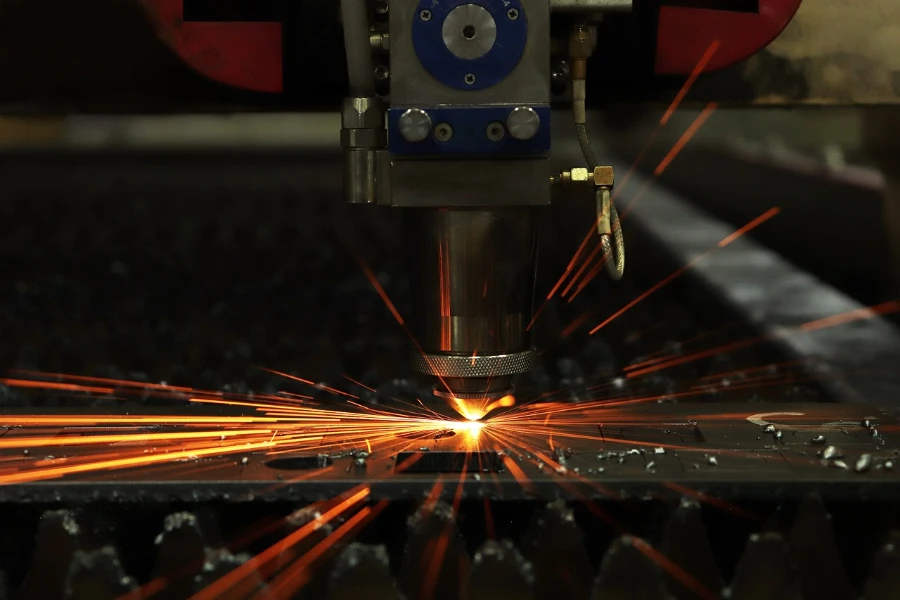

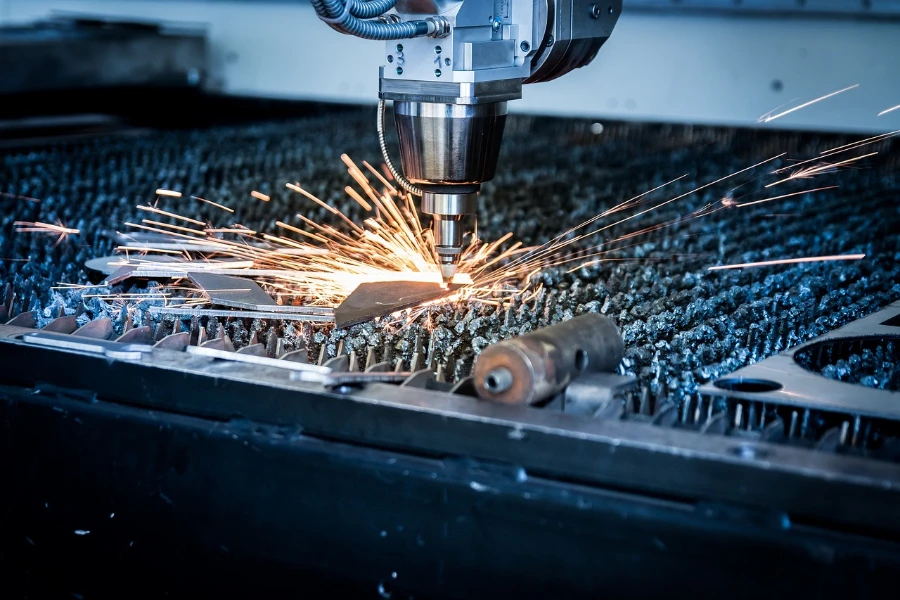

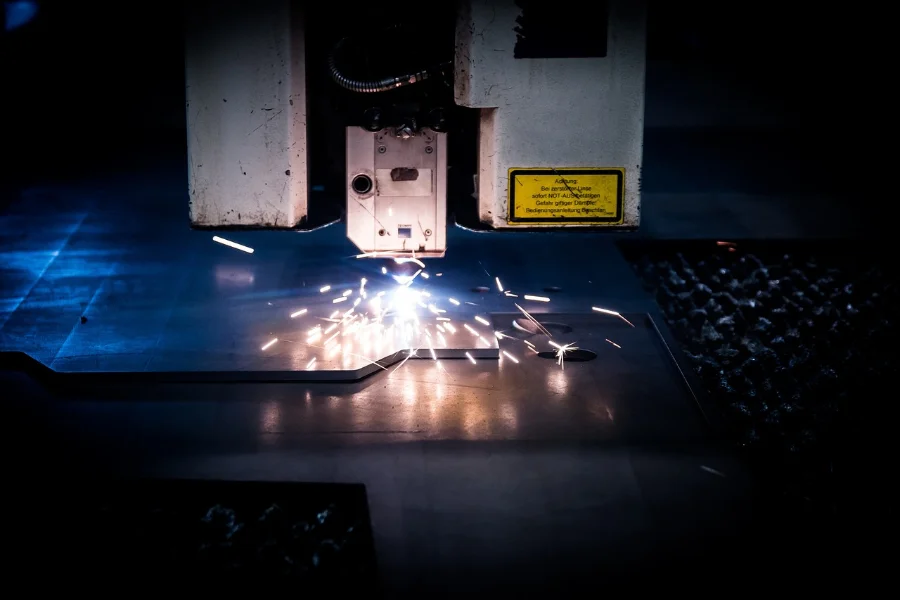

Oomatshini bokusika iLaser

Oomatshini bokusika iLaser zisetyenziswa kumashishini ahlukeneyo ukusika ngokuchanekileyo kunye noyilo lweprojekthi. Ngoncedo lomqadi welaser onamandla, lo matshini unokusika ngokuchanekileyo okanye ubhale uyilo olufunekayo kwizinto ezifana nentsimbi, iplastiki okanye umthi.

Abasiki beLaser banezinto ezininzi. Ukutshintshela ngaphandle kwezixhobo zokusika ezahlukeneyo okanye ezintsonkothileyo akuyomfuneko. Ukuseta okufanayo kunokusika iimilo ezininzi ukusuka kubunzima besixhobo esifanayo. Ngokwemvelo, obu buchule buxhomekeke kumandla alo.

Ukusika kwe-Laser thermal ikhawuleza kwaye ichaneke ngakumbi kunezinye iindlela zokusika i-thermal, njengeplasma okanye ilangatye, ukusika ukuya kubunzima obumalunga ne-10 mm. Ubunakho be-laser cutter ekugqibeleni bumisela indawo yenzuzo echanekileyo. Ukuchaneka okuphezulu kunokufumaneka ngaphandle konyango emva kokuchaneka kwe-+/-0.1 mm, kwaye umgangatho ophezulu onjalo uthetha ukuba akukho ukunyamezela okongezelelweyo kuyadingeka. Amalungu aphantse abe yikopi enye kwenye aqinisekisiwe nge +/- 0.05 mm.

Itekhnoloji yanamhlanje yokusika i-laser izenzekela kakhulu, ifuna umsebenzi omncinci wabantu. Imveliso yokugqibela isazuza kakhulu kumsebenzisi womatshini onamava. Sekunjalo, le ndlela yokusika ayibizi kakhulu kunezinye ngenxa yesantya sokusika kunye nomzamo omncinci wabantu ofunekayo.

Phakathi kuka-2020 kunye no-2024, kuya kubakho ukonyuka kwe-USD 1.02 yebhiliyoni kwimarike oomatshini bokusika i-laser, kwaye ukukhula kweemarike kuya kuthatha isantya ngeli xesha.

Iindlela eziphambili zomatshini welaser kuMzantsi-mpuma weAsia

Iindlela zomatshini we-laser wemoto yemoto

Umzi-mveliso weemoto waseMzantsi-mpuma we-Asia usebenzisa oomatshini belaser ukomeleza iinkqubo zokuvelisa, ukuphucula ukusebenza kakuhle, kunye nokufezekisa ukuchaneka okuphezulu kwimveliso yemoto. Ngenxa yoko, ishishini ligcwele iindlela ezininzi eziphucula inzuzo yomatshini we-laser.

Umzekelo, umzi-mveliso weemoto wase-Asia-mpuma we-Asia usebenzisa i-laser enamandla kakhulu ukusika izinto ezahlukeneyo ezifanelekileyo kwicandelo leemoto, njengamaphepha esinyithi, imidibaniso, kunye neetyhubhu. Ukongeza, isebenzisa oomatshini bokuwelda belaser abanamandla ukujoyina la macandelo esinyithi kwaye wonwabele ulawulo oluchanekileyo.

Kodwa akuphelelanga apho. Iinkqubo zokuvelisa ezongezelelweyo ezisekwe kwiLaser nazo zihamba phambili kushishino. Iindidi ezifana ne-selective laser melting (SLM) kunye ne-laser sintering inokuvelisa iinxalenye zemoto ezintsonkothileyo ngokuthe ngqo kwiimodeli ze-3D CAD.

Oomatshini bonyango lweLaser, enye indlela esekwe kwi-laser, inokuguqula ngokulula iipropathi zomphezulu wezixhobo zemoto. Ngokomzekelo, i-laser texturing inokudala iipatheni ezithile okanye ukuthungwa kwi-molds, ukuphucula ixesha elide kunye nokusebenza.

Iintsingiselo zemarike yomatshini we-Metal laser processing

Ishishini lokulungisa isinyithi lisebenzisa kakhulu ishishini oomatshini laser ngenxa yokuchaneka kwazo, isantya, kunye nokuguquguquka kwazo. Njengamanye amashishini, itekhnoloji yelaser ibonelela ngeenzuzo ezahlukeneyo, kubandakanya ukusika, ukuwelda, ukumakisha, kunye nokukrola.

Nangona kunjalo, umkhwa othile obalaseleyo kukucoca ngelaser. Aba matshini be-laser bemizi-mveliso banokususa ngokulula ungcoliseko, iioksidi, ipeyinti, umhlwa, kunye nezinye izinto zokugquma kumphezulu wesinyithi. Bakwabonelela ngendlela yokucoca engadibanisiyo kunye nokusingqongileyo ngaphandle kokusebenzisa imichiza okanye izinto ezirhabaxa.

Iindlela zemarike yomatshini weDiode laser

I-teknoloji ye-diode yokukhanya kunye iteknoloji ye-laser diode zombini zisetyenziswa ngokubanzi kwizikhombisi ze-laser. Nangona ukusika isinyithi nge-laser diode ekuqaleni kwakunzima, ukuqhubela phambili kwezobuchwepheshe kuliguqule ngonaphakade ishishini. Isixhobo se-Direct Diode Laser (i-DDL), okanye isitofu se-laser, sidibanisa ukukhanya okuvela kwiidiode ezininzi kwi-beam enye.

Iilaser zeDiode inokusetyenziswa kwiindawo ezimenyezelayo njengobhedu kunye ne-aluminiyam, izenza zisebenze ngakumbi kuneelaser zefiber. Isantya sokusika si-100% ngokukhawuleza kuba i-aluminium ithatha ngokukhawuleza ubude be-laser diode. Ukongeza, oomatshini be-diode abanamandla aphezulu banokusebenza ngesinyithi i-10-20% ngokukhawuleza kune-fiber lasers. Bakwabonelela ngomgangatho ongcono wecala xa usebenza ngezinto ezixineneyo.

Iintsingiselo zemarike yomatshini we-CO2 laser

Umoya omdaka (CO2) iilaser sika kwaye ukrole izinto ezahlukeneyo usebenzisa i-laser beam eyenziwe kwi-CO2, kungoko igama. Yenye yezona lasers zisetyenziswa kakhulu ngenxa yamandla ayo okusika aphezulu, ukuchaneka, kunye nesantya sokusika ngokukhawuleza. Amachiza, ukupakishwa kokutya, kunye nemizi-mveliso yombane isetyenziswa kakhulu I-laser ye-CO2 itekhnoloji enesinyithi kunye neentsimbi ezininzi ezingezizo iintsimbi ezifana neenkuni kunye neplastiki.

IiLaser lukhetho oluhle kakhulu lokusika izinto ezityebileyo kuba zigqobhoza ngokukhawuleza kwaye zivelise umphezulu ogudileyo. Imitha ye-CO2 zingabizi kakhulu kodwa zisebenzisa amandla amaninzi kunefayibha, nto leyo enyusa iindleko zokusebenza. Nangona kunjalo, oku kuxhomekeke kumandla.

Uhlobo lwe-laser, ishishini lokusetyenziswa kokuphela, kunye nejografi zinika umbono ongcono wemeko yangoku yetekhnoloji kwimarike yelaser yeCO2 yehlabathi. Iindidi zelaser zangoku zihamba ngokunqamlezayo, zivaliwe, kunye nelaser yegesi yeCO2 ehambayo. Kuzo zontathu, imfuno ye-CO2 yegesi ye-laser ibonisa izithembiso eziphezulu zokukhula ngokukhawuleza kwe-CAGR.

Iindlela zemarike yomatshini weFayibha laser

Iifayibha lasers zizixhobo ezikhethekileyo zokusika isinyithi ezinesantya esingenakuthelekiswa nanto, ukuchaneka, kunye nokuphinda-phinda. Ngokuqhelekileyo, banokusika iintsimbi ezingenayo i-ferrous kunye nentsimbi ethambileyo nengenasici. Aba matshini banokumiselwa ukusika iintsimbi ezingqindilili kakhulu kwaye banikwe amandla yi-500W+ Fiber-Optic imithombo yelaser.

Oomatshini beFayibha laser sebenza kakuhle ngokumakishwa okufana ne-annealing, etching, kunye nokukrola. Ngenxa yedayamitha yogxininiso oluyimizuzu, ezi lasers zisebenza kakhulu ekuphawuleni ulwazi olunjengamanani, iimatriki zedatha, kunye neebhakhowudi kwiintsimbi. Iilaser zeFiber zisetyenziselwa ikakhulu ukuphawulwa kwenxalenye ngokuthe ngqo ukuxhasa ukulandelelwa kwemveliso kunye neemfuno ezifanayo zokuchongwa.

Xa kuthelekiswa ne-CO2 lasers, i-fiber lasers zi-eco-friendly, ukonga amandla ngakumbi, akukho mfuneko yokugcinwa, kunye nobomi obude, oko kuthetha ukonga imali ebalulekileyo. Imfuno yefiber lasers yokucoca izicelo iyanda. Amashishini amaninzi asebenzisa izixhobo zokucoca ngelaser ukunceda ukususa ungcoliseko njengepeyinti, iioksidi, kunye nomhlwa kwiintsimbi.

Jonga ezi ndlela

Imakethi yomatshini we-laser ihlala itshintsha ngenxa yenkqubela phambili yetekhnoloji. Amashishini anokuvelisa iziphumo ezintle kwizinga elingazange libonwe ngaphambili ngenxa yokuchaneka kunye namandla oomatshini belaser.

Iindlela zentengiso zamva nje zibonisa ukuba i-CO2 kunye ne-fiber lasers ziinketho ezidumileyo ngenxa yokusebenza kwazo okuphuculweyo. Iilaser diode ezithe ngqo ziya kuba neyona CAGR iphezulu kwixa elizayo ngenxa yokuphucula umthamo wazo wokuphatha, ukulula kwenkonzo, ukuthembeka okwandisiweyo, kunye nokuncipha kweendleko zokusebenza.

Abathengisi banokugxila kwezi umatshini laser woshishino iindlela zokwandisa ukuguquguquka, ukunciphisa iindleko zenkqubo, kunye nokwenza imveliso isebenze ngakumbi.