Isiqulatho

Yintoni umzila weCNC?

Ziziphi izinto ezinokusikwa ngoomatshini be-router ye-CNC?

Zeziphi izicelo ezifanelekileyo koomatshini bomzila be-CNC?

Usebenza njani umatshini we-CNC router?

Ixabisa malini irutha ye-CNC?

Indlela yokukhetha itafile ye-router ye-CNC

Zeziphi iintlobo ezahlukeneyo koomatshini bomzila we-CNC?

Yeyiphi isoftware enokusetyenziswa koomatshini bomzila weCNC?

Zeziphi izilawuli ezinokusetyenziswa koomatshini bomzila we-CNC?

Yintoni omele uyazi ngaphambi kokuba uthenge umatshini we-router ye-CNC?

Indlela yoku-odola umatshini we-router ye-CNC

FAQs

Yintoni umzila weCNC?

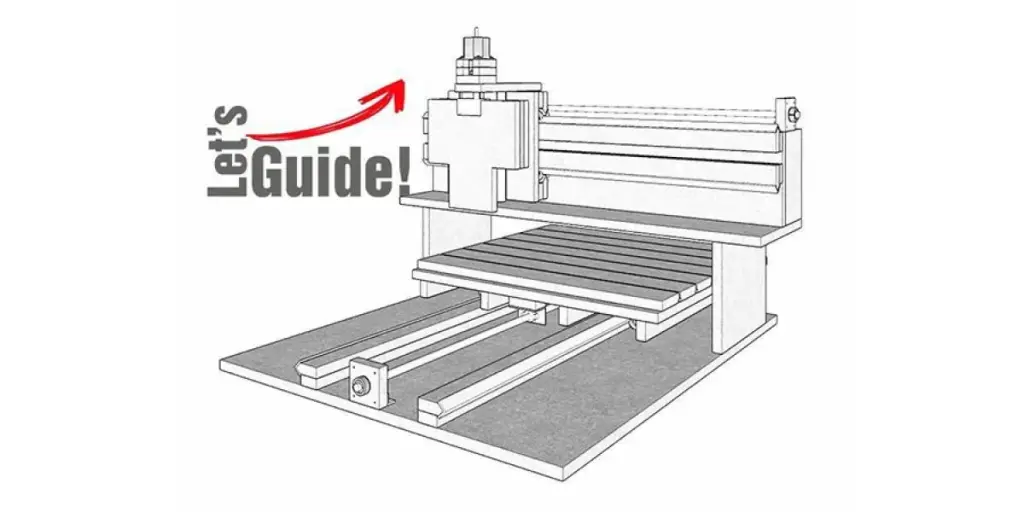

I-router ye-CNC luhlobo lwesixhobo somatshini esizenzekelayo esisetyenziswa ngenkqubo ye-CNC yokukrola ngokuzenzekelayo, ukukrola, ukusika, ukugaya, ukubhola, kunye nokugrumba kwezinto ezahlukeneyo. Izinto ezifana nemithi, igwebu, ilitye, iiplastiki, i-acrylic, iglasi, i-ACM, ubhedu, ubhedu, i-aluminium, i-PVC, kunye ne-MDF inokusetyenzwa kuyo. Aba matshini banokuvelisa iimilo ezichaneke kakhulu nezintsokothileyo kunye neecontours ngokwenza izinto ngomatshini usebenzisa isixhobo. Umatshini we-router ye-CNC ufezekisa ezi ziphumo usebenzisa ubuncinane bee-axes ezintathu, i-X, i-Y, kunye ne-Z. I-X-axis i-horizontal, ekhohlo ukuya ekunene, i-Y-axis ibuyele ngasemva nangaphambili, kwaye i-Z-axis ime nkqo, okt phezulu nasezantsi. Ezi, zibonwa ngokufuziselayo, ziphumela kwinto ebizwa ngokuba yi-portal, yiyo loo nto ii-router ze-CNC ezine-portal formation (i-X-axis eyenzelwe njengebhulorho) zidla ngokubizwa ngokuba ngoomatshini bokugaya i-portal. Ukongeza, abanye oomatshini bokungqusha bane-A-, B-, kunye ne-C-axes emele ukujikeleziswa kwe-X, Y, kunye ne-Z.

Ziziphi izinto ezinokusikwa ngoomatshini be-router ye-CNC?

Oomatshini be-router ye-CNC banokusika izinto ezininzi ezahlukeneyo, kubandakanya:

iinkuni

amagwebu

MDF

iiplastiki

Iiacrylics

ilitye

ubhedu

Brass

ialuminiyam

iglasi

ACM

ithayimthebhili

Zeziphi izicelo ezifanelekileyo koomatshini bomzila be-CNC?

Nazi ezinye zezicelo ezisebenzisekayo ezinokwenzeka koomatshini be-router ye-CNC:

- Ukukrola kwe-2D

- Ukukrola kwe-3D

- IWorkworking

- Ukwenziwa kweAluminiyam

- Ukwenziwa kweAkriliki

- Imiboniso kunye nezixhobo

- Umsebenzi wokusila wezakhiwo

- Ukwenza iKhabhinethi

- Ukwenza imiqondiso

- Ukwenza ucango

- Imveliso yefanitshala

- Ukwenza umngundo

- Imihlobiso

- Izixhobo zomculo

- I-Aerospace

Usebenza njani umatshini we-CNC router?

Umatshini womzila we-CNC ulawulwa yikhompyutha. Yonke idatha eyimfuneko, ngendlela yeekhowudi ze-G, idityaniswe kwiprogram ye-CNC. Iikhowudi ze-G zibandakanya naliphi na igama kwiprogram ye-CNC eqala ngonobumba G. Ixelela isixhobo somatshini ukuba luhlobo luni lwesenzo sokwenza, njengokuhamba ngokukhawuleza okanye imigca elawulwayo okanye i-arcs. Ekubeni ezi khowudi zisemgangathweni, zinokusekelwe kwi-software ye-CNC router esetyenziswa phantse kubo bonke oomatshini be-router ye-CNC. Xa yonke idatha ifakiwe kwaye inkqubo ye-CNC ilungele ukuhamba, umatshini we-CNC uqala ukusebenza. Abavelisi bongeze iikhowudi zabo kwi-ISO G-codes, ke ngoko, uninzi lwe-post-processors lukhona ukuvelisa iinkqubo "zokudibanisa" kwiinkqubo zeCAM zoomatshini abahlukeneyo.

Ngokujikeleza isixhobo esifanelekileyo, okanye usebenzisa i-spindle elungelelanisiweyo echasene ne-workpiece edibeneyo, intshukumo yokusika eyimfuneko kumsebenzi ofunekayo iveliswa. Oku kumiselwa kwangaphambili ngokusekelwe kwiikhowudi ze-G. Isixhobo se-CNC sijikeleza i-workpiece, sidala imilo emiselweyo. Oku kunokufezekiswa, kuxhomekeke kuyilo lwe-router, ngokufuduswa kwendawo yokusebenza kwitafile ye-router ye-CNC ehambayo. Ngokusebenzisa zonke ii-axes ezikhoyo, phantse zonke iijiyometri zeworkpiece ziyenzeka. Kunokwenziwa ezi fom zilandelayo:

Iimodeli ze-3D ezifanelekileyo kwizakhiwo kunye nokwakhiwa kwemodeli

Imiphezulu ye-3D yasimahla

I-Roto-symmetrical workpieces

Ukubhala ngoonobumba kuzo zombini i-2D kunye ne-3D

Ukukrola kwi-2D kunye ne-3D

Imiba

Izitya

Ixabisa malini irutha ye-CNC?

Ixabiso le-router ye-CNC ixhomekeke ikakhulu kuqwalaselo lwayo. Nangona unokucinga ukuba zonke iirutha ze-CNC zibukeka zifana, kukho umahluko omkhulu phakathi kwezinto abanokuzenza. Bonke oomatshini benza imisebenzi esisiseko njengokusika, ukugrumba, ukubhala ngoonobumba, ukukrola inqwelomoya, ukukhulula, njalo njalo, kodwa ukuchaneka, ukuntsonkotha, isantya, ukusebenza, kunye nexabiso lahluka kakhulu.

- Ixabiso lexabiso le-CNC encinci: $ 2,500 - $ 5,000

- Uluhlu lwexabiso lomzila we-CNC oluqhelekileyo: $ 3,000 - $ 10,000

- Uluhlu lwexabiso lomzila we-ATC CNC: $ 16,800 - $ 25,800

- 5-Axis CNC umzila ixabiso uluhlu: $95,000 - $180,000

- Smart CNC umzila ixabiso uluhlu: $8,000- $60,000.

Ngaba kukho iindleko ezongezelelweyo kunye neentlawulo xa uthenga i-router ye-CNC?

Ukongeza kumatshini ngokwawo, kuya kufuneka uthenge iphakheji yesoftware yoyilo oluncediswa yikhompyuter (CAD) ukwenza uyilo lwakho. Ezo zihlala zibaleka ukusuka kwi-2,000 ukuya kwi-15,000 yeedola.

Uqeqesho ludla ngokubiza naphi na ukusuka kwi-200 ukuya kwi-500 yeedola ngosuku. Ngokuxhomekeke kwinqanaba lolwazi lwangoku lwabasebenzi bakho, inkqubo inokuthatha iiyure ezimbalwa okanye iintsuku ezininzi. Ukufakela kwakhona kuthande ukubiza phakathi kwe-200 yeedola ukuya kwi-500 yeedola ngosuku.

Ukuthumela ngenqanawa kuqala kumakhulu aliqela eedola kwaye kunokubiza ukuya kuthi ga kwi-2,000 yeedola, kuxhomekeke kwindawo ngokuqinisekileyo.

Abanye abathengisi banikezela ngezivumelwano zebhandle ezibandakanya iindleko zoomatshini, uqeqesho, ukuhambisa, kunye nofakelo. Qiniseka ukuba ujonge ukuba zeziphi na izivumelwano abazenzayo ngaphambi kokuba benze isigqibo ngokuthenga kwakho okanye umthengisi.

Indlela yokukhetha itafile ye-router ye-CNC

Iintlobo zetheyibhile

Iintlobo eziqhelekileyo zeetafile ze-CNC router ziquka iprofayili, i-vacuum, kunye neetafile zebhloko ye-adsorption. Itheyibhile yeprofayile ye-CNC yaziwa ngokuba yitafile yokulungisa. Olu hlobo lwetheyibhile lucinezela ngokuthe ngqo i-workpiece nge-screw plate, kwaye ifanelekile ukusika, ukugoba, kunye nezinye iinkqubo, ekubeni ixesha elide umoya ungaphunyuka, i-vacuum adsorption ayikwazi ukuxutywa. Xa kuthengwa itafile yeprofayili, abathengi banokukhetha imodeli efanelekileyo kakhulu kubo, ngokusekelwe kwizinto ezimbini ezingentla. Nangona kunjalo, ukuba usebenzisa isixhobo sokusika esinobubanzi obuncinci (ngaphantsi kwe-4mm), kuba i-gap incinci, ezinye zinokuthi zifakwe i-vacuum-adsorbed kwitafile.

Itheyibhile ye-CNC ye-router vacuum inebhodi yoxinaniso kwaye yenziwe kwifiber yomthi kunye neglue phantsi koxinzelelo oluphezulu. Kukho imibhobho okanye izikhewu phakathi kwemigangatho yefiber yomthi kwaye emva kokuplaga iteyiphu yokutywina, ipompo yokucoca inokuvulwa ukuze idale i-vacuum kwaye ibambe i-workpiece ngokukhuselekileyo etafileni. Oku konga ixesha lokuhamba malunga ne-vices okanye izikrufu kwaye ifaneleke ngakumbi ukuveliswa kobuninzi beengcango zokhuni. Ngamanye amaxesha kunokuba yimfuneko ukubeka ibhodi ye-MDF encinci kuqala. Ibhodi ye-MDF ibekwe kwi-CNC router vacuum suction table ukukhusela i-milling cutter ukuba yonakalise i-worktable. Uxinzelelo kwindawo ekufutshane nebhodi yoxinaniso lungaphantsi kakhulu kunoxinzelelo lwe-atmospheric kwelinye icala, lwenza uxinzelelo olubi, ngoko ke i-workpiece ibanjwe ngokuqinileyo kwaye ingabikho izikrufu ezicaphukisayo okanye izikhonkwane endleleni. Umzekelo, ngumgaqo ofanayo naxa amacwecwe amabini eglasi ebambene kwaye kunzima ukuwahlula. Emva kokuba itywina lingasekho, akukho xinzelelo olubi, ngoko ke uxinzelelo kumacala omabini epleyiti yokusebenzela luyafana, kwaye kuba lula ukuhlukana.

Ubungakanani betafile

Ubungakanani betafile ye-CNC ye-router eqhelekileyo iquka: 2′ x 2′, 2′ x 3′, 2′ x 4′, 4′ x 6′, 4′ x 8′, 5′ x 10′, kunye 6′ x 12′.

Yeyiphi i-CNC router spindle omele ukhethe?

I-spindle yenye yezona zinto zibalulekileyo zomatshini we-CNC router. Umatshini ngokubanzi kufuneka uxhotyiswe nge-spindle ephezulu yokusebenza ukuzalisekisa imisebenzi yawo. Umgangatho we-spindle uchaphazela ngqo isantya sokulungisa kunye nokuchaneka komatshini we-CNC umzila, ngoko ke ukukhetha i-spindle efanelekileyo kubaluleke kakhulu. Ke, nantsi into ekufuneka uyiqwalasele:

1. Gweba ukuba ingaba i-spindle ikumgangatho ophezulu, okanye ikhangeleka iphantsi.

1.1. Ngaba i-spindle motor isebenzisa iibheringi ezichanekileyo? Ukuba iibheringi ezichanekileyo azisetyenziswanga, i-spindle motor iya kutshisa emva kokujikeleza kwexesha elide, okuya kuchaphazela ubomi benkonzo ye-spindle motor.

1.2. Ngaba isandi siyafana kwaye siyahambelana xa sijikeleza ngesantya esahlukileyo, ngakumbi ngesantya esiphezulu?

1.3. Ngaba intambo yokusonta iphantsi kwamandla kwicala leradial? Inqaku eliphambili lereferensi kukuba ngaba kunokwenzeka ukusika izinto ezinzima ngesantya esiphezulu. Ezinye ii-spindles zinokusika kuphela izinto ezilukhuni ngesantya esiphantsi kakhulu, kungenjalo, ukusebenza kwe-spindle kuya kuba mbi, okuya kuchaphazela ukuchaneka kwe-spindle emva kwexesha elithile, okanye kubangele ukungasebenzi kakuhle.

1.4. Ukuba ufuna ukusetyenzwa okuphezulu, isantya sokusebenza kufuneka sikhawuleze, ngokusikwa kwemela enkulu. Xa ulungisa imathiriyeli yomthi owomeleleyo, uya kufuna injini yokusonta enamandla e-2.2KW okanye ngaphezulu.

1.5. Ulungelelwaniso oluqhelekileyo lomatshini we-CNC we-spindle luyahluka ngokuhambelana nezixhobo zokusebenza.

2. Ukukhetha i-CNC router spindle efanelekileyo ngokwezicelo ezahlukeneyo.

2.1. Into ebhalwe ngumatshini we-router ye-CNC epapashiweyo yinto ethambileyo, ngoko ke amandla okuphotha kufuneka abe yi-1.5kw - 3.0kw. Ukuba ukhetha olu hlobo, unokufezekisa umzila ngelixa ugcina iindleko.

2.2. Amandla e-CNC amaplanga e-router spindle motors anokukhethwa ngokobulukhuni bomthi oza kucutshungulwa. Nangona kunjalo, malunga ne-2.2kw - 4.5kw, kufuneka yenze umsebenzi.

2.3. Amandla okusonta koomatshini be-CNC bamatye aphezulu kakhulu, malunga ne-4.5kw - 7.5kw, kunye ne-5.5kw motor spindle yeyona isetyenziswa kakhulu.

2.4. I-Foam CNC router amandla okuphotha kufuneka kwakhona akhethwe ngokobulukhuni be-foam ukuba iqhutywe. Ngokwesiqhelo, i-1.5kw – 2.2kw iyakuhlangabezana neemfuno zabathengi.

2.5. Ngenxa yobunzima obuphezulu koomatshini bentsimbi ye-CNC ye-router, amandla e-spindle motor aphakathi kwe-5.5kw - 9kw.

Ngamanye amagama, i-spindle motor enamandla kakhulu ichitha amandla ombane kwaye yonyusa ixabiso lokuqala lokuthenga. Ukuba umbane uphantsi kakhulu imfuno yamandla omzila ayisayi kufumaneka. Ke ngoko, ukukhetha i-spindle motor power efanelekileyo kuyafuneka.

3. Ubudlelwane phakathi komatshini we-router ye-CNC kunye nezixhobo zomzila.

Okukhona ukuqina kwesixhobo sokujikeleza, kokukhona sisezantsi isantya sokujikeleza. Yingqiqo nje le. Izinto ezilukhuni zifuna ukucolwa kancinci kwaye ukuba isantya sokujikeleza sikhawuleza kakhulu, isixhobo singonakala. Iphezulu i-viscosity yezinto zokuhambisa, iphezulu i-spindle esetyenzisiweyo. Oku ikakhulu kwiintsimbi ezithambileyo okanye izinto ezenziwe ngabantu.

Ububanzi besixhobo esisetyenziswa kumatshini we-CNC router ikwayinto ebalulekileyo ekumiseleni isantya sokusonta. Idayamitha yesixhobo esisebenzayo inxulumene nesixhobo sokulungisa kunye nomgca wokucubungula. Ubukhulu bedayamitha yesixhobo, isantya esicothayo siya kuba. Ukumisela isantya sokusonta kufuneka kusekwe kusetyenziso lwemoto yokuphotha. Xa isantya sokuphotha sincipha, amandla emveliso yemoto nawo ayancitshiswa. Ukuba amandla aphumayo awela kwinqanaba elithile, liya kuchaphazela ukucubungula, okuya kuchaphazela kakubi ubomi besixhobo kunye nomsebenzi. Ke, xa ujonga isantya sokusonta, qiniseka ukuba i-spindle motor inamandla afanelekileyo okuphuma.

Zeziphi iintlobo ezahlukeneyo koomatshini bomzila we-CNC?

Makhe sijonge kwiindidi ezili-10 eziqhelekileyo zoomatshini bomzila we-CNC, ngokwemisebenzi eyahlukeneyo, izembe, izixhobo, kunye nezicelo.

Uhlobo lwe-1: Ii-router ze-CNC ezincinci kumashishini amancinci

Uhlobo lwe-2: Ii-router ze-CNC zokuzonwabisa kwii-hobbyists

Uhlobo lwe-3: Iirutha ze-CNC zeDesktop kwiivenkile zasekhaya

Uhlobo lwe-4: Ii-router ze-Industrial CNC zokwenziwa komthi

Uhlobo lwe-5: Ii-routers ze-ATC CNC ezinesixhobo esizenzekelayo esitshintshayo

Uhlobo lwe-6: Oomatshini be-CNC yokuzalela ukwenza ikhabhinethi

Uhlobo lwe-7: I-4-Axis CNC imizila enetafile ejikelezayo

Uhlobo lwe-8: Ii-router ze-5-Axis ze-CNC ze-3D imodeli

Uhlobo lwe-9: Ii-router ze-Metal CNC ze-aluminium

Uhlobo lwe-10: Ii-router ze-Foam ze-CNC ze-EPS kunye ne-Styrofoam

Yeyiphi isoftware enokusetyenziswa koomatshini bomzila weCNC?

Type3

I-Type3 sisisombululo sesoftware ye-CNC esijikelezayo kwiimfuno zoyilo lwemizobo yeplanga. Isebenza phantsi kwenkqubo yeMicrosoft Windows, ineyona phakheji yesoftware yoyilo lwegraphic, kwaye idityaniswe ngokusondeleyo nenkqubo yokusetyenzwa. Ukusuka koonobumba abalula ukuya kwipatheni entsonkothileyo, iType3 inemisebenzi enamandla kunye nokuguquguquka kokusombulula zonke iingxaki zokukrola. I-Type3 ilungela zonke iimfuno zakho kwaye kulula ukuyifunda kunye nokusetyenziswa. Yisoftware ejikelezileyo yokuyila kunye nokusebenza ngokukrola. I-Type3 ingabala ngokuchanekileyo indlela yesixhobo esinemigangatho emithathu, yandise indlela yokulungisa umatshini, ivelise indlela ye-CNC yomzila, kwaye ekugqibeleni ivelise ikhowudi ye-CNC yomzila. Unokukhetha ngokukhululekileyo iintlobo ngeentlobo zezixhobo kunye no-drill kubandakanya i-cone, i-spherical, kunye neentlobo ze-cylindrical zomzila.

Ucancam

I-Ucancam yisoftware ekhethekileyo edibanisa uyilo oluncediswa yikhompyuter (CAD) kunye nemveliso encediswayo (CAM). Isetyenziswa kakhulu kwizicelo ezininzi ezinje ngentengiso, imiqondiso, izipho, umhombiso, ubugcisa, ukusetyenzwa komthi, kunye nokubumba, ukukhankanya nje ezimbalwa.

Isoftware ye-Ucancam inoyilo lwemizobo enamandla kunye nemisebenzi yokuhlela, ixhasa igalelo lokulungelelanisa kwaye inokuzoba ngokuchanekileyo imizobo. Ikwabonelela ngemisebenzi efana nokukopa ibhetshi, ukuguqulwa kobugcisa, ukunqampuna okuguquguqukayo, kunye nokuhlelwa kweenodi ukuququzelela ukuhlelwa kwemizobo kunye nokuguqulwa. Ukuzenzela indlwane okuzenzekelayo kunye nokunxibelelana kwandisa izinga lokusetyenziswa kwezinto kunye neeseti ngokukhawuleza.

Ngokukhawuleza kunye nechanekileyo indlela yokubala indlela yesixhobo se-Ucancam post-machining ilungele ukuseta iimfuno zekhowudi zoomatshini abahlukeneyo. Iyanciphisa umonakalo kwisixhobo okanye kwizinto eziphathekayo kwaye ayishiyi amanqaku eemela kwindawo yokusika. I-Cycloid machining ibonelela ngenkxaso yobugcisa eyomeleleyo yokusika ilitye eliqinileyo, iglasi, kunye nezixhobo ezinqabileyo. Ngelo xesha, iindlela ezahlukeneyo zomatshini ezibandakanya i-3D, i-lining center, i-drilling, i-inlaying, i-edge and cornering, i-round carving, i-carving image, kunye ne-require yomfanekiso ikhona, kuxhomekeke kwiimfuno zabathengi. Ukongeza, ukusetyenzwa kokulinganisa, imisebenzi yokulinganisa, kunye neziphumo ezifanelekileyo kunye nokukhawuleza kweziphumo zokubonisa kunciphisa inkqubo yovavanyo lomatshini kwaye ngoko ke kunciphisa iindleko zokwenza.

ArtCAM

Uluhlu lwemveliso yesoftware ye-ArtCAM, eveliswe yinkampani yase-UK Delcam, ibonelela ngemodeli ekhethekileyo ye-CAD, kunye ne-CNC kunye ne-CAM yokulungisa isisombululo. Sisisombululo esithandwayo se-CAD/CAM sesoftware yoyilo oluntsonkothileyo olunamacala amathathu, uyilo lobucwebe, kunye nokusetyenzwa. Inokuguqula ngokukhawuleza iingcamango ze-2D kwiimveliso zobugcisa ze-3D. I-interface ye-Chinese yonke ivumela abasebenzisi ukuba bayile kwaye basebenze isiqabu se-3D ngokulula ngakumbi, ngokukhawuleza, kwaye ngokuguquguqukayo. Isetyenziswa kakhulu kwimimandla yemveliso yokukrola, ukuveliswa kokungunda, imveliso yamatye anqabileyo, uyilo lokupakisha, ukuveliswa kweembasa kunye neengqekembe, kunye nokwenza imiqondiso.

Uluhlu lwesoftware yeDelcam ArtCAM lunokuguqula idatha yendiza efana neidrafti ezithathwe ngesandla, iifayile ezikheniweyo, iifoto, iimephu zegreyscale, iCAD, kunye nezinye iifayile, zibe ziimodeli ezicacileyo nezigqwesileyo ze-3D zoncedo lwedijithali, kunye nokuvelisa iikhowudi ezinokuqhuba ukusebenza kwesixhobo somatshini we-CNC. I-ArtCAM ibandakanya ubutyebi beemodyuli ezisebenza ngokupheleleyo, zibaleka ngokukhawuleza, zithembekile, kwaye ziyila ngokugqithisileyo. Ngokusebenzisa i-Delcam ArtCAM eveliswe iimodeli zoncedo, imodeli yokunceda enzima ngakumbi inokuveliswa ngemisebenzi ye-Boolean efana nomanyano, ukuhlangana, umahluko, indibaniselwano engafanelekanga, i-superposition, kunye ne-splicing. Ukongeza, unokwenza kwaye usebenze isiqabu esiyilelweyo. Abasebenzisi abadingi kuchitha ixesha kunye nemali ukwenza iimodeli zokwenyani kuba banokubona ngokubonakalayo iziphumo zoyilo lokwenyani phaya esikrinini.

Alphacam

I-Alphacam yenziwe nguLycome waseCoventry, e-UK, kwaye iphakheji yesoftware yeCAM enamandla. I-software ye-CNC ye-router ine-contour milling enamandla kunye nenani elingenamkhawulo wezixhobo ze-pocket machining ezinokuthi zihlambulule ngokuzenzekelayo izinto eziseleyo kunye nokwenza ngokwezifiso izicwangciso. Umendo wesixhobo kunye nesantya zivela kuzo zonke iifestile ngaxeshanye ukwenzela ukulinganisa okuguquguqukayo.

I-Alphacam isoftware yokuzalela ngokuzenzekela ngoku iyeyona iphambili isoftware esetyenziswa kwishishini lokulungisa umnyango wekhabhathi. Inzuzo yayo enkulu kukuba uhlobo lomnyango lufuna kuphela ukuseka imodeli yokucubungula (indlela yesixhobo) kanye, kwaye inokuqonda ukuxhamla ngokuzenzekelayo kwanoma yimuphi ubungakanani ngaphandle kwesidingo sokuphinda udwebe. Ngenxa yoko, ukusebenza kakuhle kuphuculwe kakhulu xa kuthelekiswa nesoftware yemveli.

Umbono weKhabhinethi (CV)

Umbono weKhabhinethi yinkqubo ye-3D ehlanganisiweyo yekhabhathi yoyilo ehambelana neWindows. Inokuqonda ngokulula uyilo oluncedisayo oluchanekileyo kunye noyilo lobuchwephesha begraphic ngokungqinelana ngqongqo kunye neenkcukacha zoyilo lweshishini. Inikezelwe kwiikhabhathi kunye neewadi, kulula ukuyisebenzisa kwaye inamandla, uMbono weKhabhinethi unokuncedisa ngokuchanekileyo ekusekweni kweendonga, ukhethe kunye noyilo lwemizobo yemveliso yenkqubo yenkampani, kunye nokuvelisa ngokuhambelanayo izicwangciso zomgangatho, ukuphakama, iimbono zecala, ukunikezelwa kwe-dimensional-dimensional, kunye neembono eziqhumayo zendibano. Isenokwenza ngokuzenzekelayo iimbono zonikezelo ezininzi kwaye ingqinelane ngokupheleleyo neemfuno ezibonwayo zomthengi. Ngaphaya koko, ukuveliswa okuzenzekelayo kweekowuti zokuthengisa kunye noluhlu lwamacandelo, ukwahlula ngokuzenzekelayo, kunye noyilo kunye nokwahlula, kuthatha imizuzu engama-30 kuphela, kunye neempazamo zero kunye nokuthotyelwa ngokungqongqo kwimigangatho yoshishino.

Ikhabhinethi echanekileyo echanekileyo kunye noyilo lwevenkile lunokwenziwa ngexesha langempela kwivenkile, ngokweemfuno ezilungiselelwe umthengi, iindlela ezahlukeneyo zokunikezela, kunye noluhlu lokuthengisa. Oku ke kudibanisa kunye nesiphelo se-post-processing yomzi-mveliso, ukubeka ii-odolo ukude ngelixa ukhokela inkqubo yokuvelisa.

Zeziphi izilawuli ezinokusetyenziswa koomatshini bomzila we-CNC?

UMlawuli we-Mach3 CNC

Xa usebenza kwikhompyuter, i-Mach3 yinkqubo yokulawula isixhobo esinamandla kunye neyoqoqosho. Ngoyena mlawuli we-CNC owaziwayo kwihlabathi jikelele. Ukusebenza kwe-Mach3 kufuna ikhomputha enobuncinci iprosesa ye-1GHz kunye ne-1024—768 pixel display. Inkqubo yeWindows inokusebenza ngokupheleleyo kolu lungelelwaniso. Iikhompyuter zedesktop zisebenza ngakumbi kwaye zinoqoqosho kuneekhompyuter zamanqaku. Xa ikhompyutha ingasetyenziswanga ukulawula isixhobo somatshini, ingasetyenziselwa eminye imisebenzi yocweyo. I-Mach3 igqithisa iisignali ikakhulu kwi-parallel port, kodwa ingagqithisela nakwi-serial port. Iinjini zokuqhuba zesixhobo somatshini ngamnye kufuneka zikwazi ukufumana zombini imiqondiso yokubetha kwenyathelo kunye nemiqondiso ethe ngqo. Zonke iimotor zestepper, DC servo motors, kunye neAC servo motors ezineencoders zedijithali ziyahlangabezana nale mfuneko. Kufanelekile ukuqaphela ukuba ukuba ufuna ukulawula isixhobo esidala somatshini we-CNC ngenkqubo ye-servo esebenzisa isixazululi ukulinganisa indawo yesixhobo, kuya kufuneka utshintshe i-axis nganye ngemoto entsha yokuqhuba.

NC studio CNC Controller

Isilawuli se-NC studio se-CNC sivela e-China. Inkqubo ye-CNC inokuxhasa ngokuthe ngqo i-G-code kunye neefomathi zekhowudi ye-PLT kunye nendlela efanelekileyo eyenziwa yi-MASTERCAM, i-UG, i-ArtCAM, i-CASMATE, i-AUTOCAD, i-CorelDraw, kunye nezinye isofthiwe ye-CAM / CAD. Ukongeza kwi-manual, ukunyathela, ngokuzenzekelayo, kunye nemisebenzi yokubuyisela imvelaphi yomatshini, i-studio ye-NC nayo inemisebenzi ekhethekileyo efana nokulinganisa, ukulandelwa kokubonisa okuguquguqukayo, ukusetwa kwesixhobo esizenzekelayo se-Z-axis, imemori ye-breakpoint (ukwenziwa kweprogram yokutsiba), kunye nokuqhutyelwa kwe-axis ejikelezayo. Le nkqubo ingasetyenziswa kunye neerotha ezininzi ze-3D CNC kunye ne-3D CNC mill. Ilungele zonke iintlobo zokusetyenzwa komngundo ontsonkothileyo, iiparaphernalia zentengiso, ukusika, kunye namanye amashishini.

Umlawuli we-Syntec CNC

I-Syntec yinkqubo yolawulo ye-CNC eyaziwayo ephuhliswe yi-Taiwan Syntec Technology Co. Ltd. I-Taiwan Syntec okwangoku yi-PC-based based controller brand ye-CNC ekhethekileyo kwi-R & D, ukuvelisa, ukuthengisa, kunye nenkonzo yabalawuli be-PC-based CNC. Inkqubo ye-Syntec ye-CNC umatshini we-router inikeza ukusebenza okuzinzile, ukusebenza kakuhle kunye nokuguquguqukayo, inkxaso yeprogram ezimbini, imiboniso yeprogram ezintathu kunye ezine, kunye nokulungelelanisa umatshini. Ukuhlelwa kwenkqubo kunye nokujongwa kwenkqubo kwenziwa ngokwahlukileyo, ukulungelelaniswa kweqela ngalinye le-axis liboniswa ngokuzimeleyo, kwaye iqela ngalinye le-axis linokulinganiswa ngexesha elifanayo ukujikeleza ukulungelelanisa inkqubo. Kulula ukubhala inkqubo yokucubungula, ukwenza inkqubo ye-dimensional-dimensional kumphezulu othambekileyo, kwaye uphumeze ukugaya, ukugrumba, kunye nokucofa.

Inkqubo isekela indlela yokulawula ibhasi ye-Yaskawa, eyanciphisa kakhulu iindleko ze-wiring kunye neemfuno zendawo, kwaye iphucula indleko-esebenzayo. Indlela yokulawula unxibelelwano lwebhasi yaseYaskawa inceda ekuphuculeni iingcingo kunye neengxaki zokwandiswa kwabalawuli benjongo yesiqhelo yohlobo lwepulse ukuze inkqubo ibe lula, yande ngakumbi, kwaye kulula ukuyihlanganisa.

UMlawuli weDSP

Umlawuli we-DSP yinkqubo yokulawula ukubamba enokuthi isebenze ngaphandle kweintanethi. Inokwahlulwa kwikhompyuter ngexesha lenkqubo yokukrola kwaye inokulawula ngokuthe ngqo umatshini wokukrola. Ixhamla ekusebenzeni komqheba, uyilo lobuntu, umboniso omkhulu wesikrini, ujongano lweelwimi ezininzi, ukusebenza lula, kunye nokugcinwa ngokulula ngakumbi. I-algorithm ekhethekileyo yoqikelelo olukrelekrele yamkelwa ukunika umdlalo opheleleyo kumandla emoto, ukuqonda ukuqhubekeka kwesantya esiphezulu, ukulungelelanisa iijika kunye nemigca ethe tye, kwaye wenze iijika zibe mtyibilizi.

Inkqubo ineSuper yokulungiswa kwempazamo, enokuthi ihlole kwangaphambili amaxwebhu okucubungula, ukuthintela ukubhala okanye ukuyila iimpazamo kumaxwebhu okucubungula, kunye nokuthintela ukubekwa kwezinto ngaphaya koluhlu lokucubungula.

NK CNC Controller

Inkqubo yokulawula uchungechunge lwe-NK ngumatshini woqoqosho wonke-kwinye enokuthembeka okuphezulu kunye nokusebenza kweendleko eziphezulu. Ingenise ukutshintshwa kwe-micro, izitshixo zepaneli zinokuthi ziqwalaselwe, kwaye izibuko zexesha zingenziwa ngokwezifiso, ukubonelela ngeparameter yokungenisa kunye nokuthumela ngaphandle, kunye nemisebenzi elula kunye ekhawulezayo yokugcina inkqubo. Ibhodi terminal ngasemva zonke-in-enye umatshini ibonelela 24V igalelo amandla port, izibuko USB, izibuko handwheel, izibuko ibreyike igalelo, port ibrake output, port output analog, servo drive interface (X-axis, Y-axis, Z-axis) efunwa yinkqubo. Ikwanayo ne-16 yenjongo jikelele yokufaka amazibuko kunye ne-8 yenjongo jikelele yonxibelelwano lwemveliso yokudlulisa. Iphaneli yokusebenza ineqhosha lokumisa likaxakeka, iqhosha lamandla, i-spindle override, kunye nokutshintsha kwebhendi yomgangatho wesondlo.

Yintoni omele uyazi ngaphambi kokuba uthenge umatshini we-router ye-CNC?

Phambi utyalo-mali kumatshini umzila CNC, okanye nawuphi na umatshini iinkuni CNC, luluvo oluhle ukutyelela umsebenzisi okhoyo kwaye ufumane i-akhawunti mathupha kumatshini kumntu oye wasebenzisa okunene. Zama ukutyelela wedwa, ngaphandle komthengisi ngeenxa zonke, ukuze uve ngokwenene ukuba ibasebenzele njani.

Ukuba awukwazi ukufumana ivenkile eqhuba umatshini we-CNC ofuna ukujonga kuwo, unokubukela umboniso nokuba ngumntu okanye kwi-intanethi. Le yeyona ndlela yokuqonda indlela umatshini we-CNC osebenza ngayo, kwaye unokuwubona ugqibezela umsebenzi ukusuka ekuqaleni ukuya ekugqibeleni.

Indlela yoku-odola umatshini we-router ye-CNC

1. Ukubonisana: siya kucebisa iikhithi ze-router ze-CNC ezifanelekileyo kuwe emva kokuvavanya iimfuno zakho, ezifana nezinto ofuna ukuzikrola kunye nobukhulu bezinto eziphathekayo (ubude x ububanzi x ubukhulu).

2. Intelekelelo yexabiso: Siza kukuthumelela ikowuti yasimahla kwiikiti zakho ze-CNC router ngamaxabiso afikelelekayo.

3. Uvavanyo lwenkqubo: Omabini amacala avavanya ngononophelo kwaye axoxe ngazo zonke iinkcukacha zomyalelo ukuthintela nakuphi na ukungaqondani.

4. Ukufaka iodolo: Ukuba konke kuvunyelwene, siya kukuthumelela i-PI (i-Invoyisi yeProforma), size sisayine isivumelwano nawe.

5. Imveliso: Siza kulungiselela imveliso ngokukhawuleza xa sifumana isivumelwano sakho sokuthengisa esayiniweyo kunye nediphozithi. Uya kugcinwa unolwazi ngalo lonke inqanaba lenkqubo.

6. Ukuhlolwa: Inkqubo yokuvelisa iya kuba phantsi kokuhlolwa rhoqo kunye nokulawula umgangatho ongqongqo. Umatshini womzila we-CNC ogqityiweyo uya kuvavanywa ukuqinisekisa ukuba usebenza ngokugqibeleleyo ngaphambi kokuba ushiye umzi-mveliso.

7. Ukuhanjiswa: Siya kulungiselela ukuhanjiswa ngokwemiqathango kwikhontrakthi emva kokuqinisekiswa komthengi.

8. I-Customs clearance: Siya kubonelela kwaye sihambise onke amaxwebhu ayimfuneko okuthumela umthengi kumthengi kwaye siqinisekise ukukhutshwa kwe-customs egudileyo.

9. Inkxaso yokuthengisa emva kokuthengisa kunye nenkonzo: Sinikezela ngenkxaso yobugcisa be-clock-clock kunye nenkonzo ye-router ye-CNC ngefowuni, i-imeyile, i-Skype, okanye i-WhatsApp.

FAQs

Uwuseta njani, ufake, kwaye ulungise umatshini womzila we-CNC

Inyathelo 1. Ukumisela isakhelo somatshini.

1.1. Vula ibhokisi yokupakisha kwaye ukhangele ukuba umatshini ubonakala ulungile.

1.2. Bala amalungu omzimba ngokoluhlu lokupakisha.

1.3. Beka ngokuthe ngcembe umatshini we-router ye-CNC kwisiseko kunye neenyawo ezine phantsi.

1.4. Lungisa iinyawo ukuqinisekisa ukuba indawo yokusebenza yomatshini ikwinqanaba.

1.5. Susa inxalenye yesigqubuthelo sangaphandle kwaye usebenzise ilaphu lesilika elicocekileyo kunye ne-kerosene (okanye i-petroli) ukucoca i-oyile ye-anti-rust kwi-screw ye-lead kunye ne-guide yesikhokelo, ukususa nayiphi na i-oyile yokuthambisa kunye nokungcola.

1.6. Yongeza ioyile yokuthambisa kwiindawo ezishukumayo ezifana nesikrufu sokukhokela kunye nesikhokelo sikaloliwe.

1.7. Misa isiciko sangaphandle ngelixa uqaphele ukuba ungangqubani neendawo ezihambayo.

1.8. Gcoba isakhelo somatshini kakuhle.

Inyathelo 2. Faka izixhobo zerouter ye-CNC.

2.1. Fakela itanki yamanzi okupholisa injini yokupholisa, qhagamshela itanki kunye nombhobho wokupholisa wemoto yokupholisa kwaye wongeze amanzi okupholisa kwitanki yamanzi, ekufuneka ibe ngamanzi athambileyo.

2.2. Faka inkqubo yokupholisa i-workpiece, qhagamshela itanki yokupholisa kwindawo yokuphuma kwamanzi kwi-bed diversion groove kunye nombhobho wamanzi, kwaye udibanise umbhobho wamanzi ophezulu. Yongeza isixhobo sokupholisa esichaziweyo kwibhokisi yokupholisa yesixhobo sokusebenza.

2.3. Faka isixhobo sokucwangcisa isixhobo kwaye uqhagamshele kwaye utshixe umgca wesixhobo sokuseta isixhobo kunye nojongano lwesixhobo sokuseta isixhobo.

Inyathelo 3. Misa ikhabhinethi yokulawula umbane.

3.1. Gcoba ikhabhinethi yokulawula umbane kakuhle.

3.2. Qhagamshela kwaye utshixe ujongano lokufakwa kwesixhobo somatshini ngamnye kunye nojongano oluhambelanayo lwekhabhathi yolawulo lwekhabhathi enentambo yokulawula.

3.3. Qhagamshela ujongano lolawulo lwekhabhathi yombane kwikhomputha yolawulo ngentambo yolawulo, kwaye uyikhusele ngezikrufu.

3.4. Qhagamshela kwaye utshixe ujongano phakathi kwekhibhodi yokusebenza kunye nekhabhathi yolawulo lombane ngentambo yokulawula.

3.5. Vala umbane wokulawula umbane wekhabhinethi yombane kwaye udibanise isiseko sombane kwi-220V, i-50HZ unikezelo lwamandla.

Inyathelo 4. Faka inkqubo yolawulo lwe-CNC kunye nesoftware.

4.1. Vula ikhompyutha yokulawula.

4.2. Faka inkqubo yokulawula umatshini we-CNC eqhotyoshelweyo.

Inyathelo 5. Ukulungiswa kwezixhobo kunye nokusebenza kwesilingo.

5.1. Emva kokujonga ukuba zonke iintambo zesignali zixhunyiwe ngokuchanekileyo, kwaye isiseko esifunekayo siyanelisa, vula umbane wokulawula umbane wekhabhinethi kwaye ufudumale imizuzu eyi-10.

5.2. Sebenzisa ikhibhodi esebenzayo ukujonga ukuba imeko yesixhobo somatshini kunye nentshukumo iqhelekile.

5.3. Qhuba uvavanyo lwe-idling kwaye wongeze ioyile yokuthambisa kwindlela yokuhamba.

Uwusebenzisa njani umatshini womzila we-CNC

1. Seta uyilo kunye nokucwangcisa ngokweemfuno. Emva kokubala indlela echanekileyo, gcina umendo wesixhobo owenziweyo njengefayile ye-router ye-CNC eyahlukileyo.

2. Emva kokujonga ukuba umendo uchanekile, vula ifayile yendlela kwindlela yokulawula ye-CNC (i-preview ikhona).

3. Lungisa izinto kwaye uchaze imvelaphi yomsebenzi. Vula i-spindle motor kwaye ulungelelanise iiparamitha ngokuchanekileyo.

4. Vula amandla kwaye usebenzise umatshini.

Isibane sesalathisi samandla siya kukhanyisa emva kokuvula iswitshi yamandla. Umatshini uya kwenza umsebenzi wokusetha kwakhona kunye nokuzijonga, i-X-, Y-, kunye ne-Z-axes ibuyela kwindawo engu-zero, kwaye emva koko iqhube kwiindawo zabo zokuqala zokulinda (imvelaphi yokuqala yomatshini). Sebenzisa umlawuli ukulungelelanisa i-X-, Y-, kunye ne-Z-axes kunye nendawo yokuqala (imvelaphi yokucubungula) yomsebenzi womzila. Khetha isantya sokujikeleza esifunekayo kunye nesantya sokutya ukubeka umatshini we-CNC kwindawo yokumisa ukusebenza. Dlulisa ifayile ehleliweyo kumatshini womzila we-CNC ukuze ugqibezele ngokuzenzekelayo umsebenzi woyilo lomzila.

Uwugcina njani umatshini we-router ye-CNC

- Susa uthuli kwibhokisi yombane rhoqo (ngokokusetyenziswa), kwaye ukhangele ukuba iitheminali zocingo kunye nezikrufu zecandelo ziqinile ukuqinisekisa ukusetyenziswa okukhuselekileyo nokuthembekileyo kwesekethe.

- Emva kokusetyenziswa ngalunye, qiniseka ukuba uhlambulule naluphi na uthuli kunye nenkunkuma kwiqonga lomatshini kunye nenkqubo yokuhambisa, ngaphandle koko uthuli oluninzi kunye nokungcola kuya kungena kwi-screw, umzila wesikhokelo, kunye nokuthwala. Ukumelana nokujikeleza kwe-screw ye-lead kunye nokuthwala kukhulu, oku kunokukhokelela ekuxhumeni kunye nokuchithwa xa isantya sokukrola sikhawuleza kancinci. Qinisekisa ukuba inkqubo yothumelo (X-, Y-, Z-axis) ithambisa kwaye ifakwe i-oyile rhoqo (ubuncinci ngeveki).

- Kucetyiswa ukuba umatshini we-router ye-CNC awuqhubeki ngokuqhubekayo ngaphezu kweeyure ze-10 ngosuku.

- Impompo yamanzi kunye ne-spindle ziyahambelana. Amanzi ajikelezayo kufuneka atshintshwe ukuze kugcinwe amanzi ecocekile kwaye kuthintelwe indawo yokupompoza ukuba ivaleke. Oku kuya kuphinda kuthintele i-spindle epholileyo yamanzi ekugqithiseni kwaye ibangele umonakalo wecandelo kwaye iqinisekise ukusebenza okuqhelekileyo kwempompo yamanzi. Ungaze uvumele umsonto wokusonta opholiswe ngamanzi ukuba usebenze ngaphandle kwamanzi aneleyo.

- Ukuba umatshini awusetyenziswa ixesha elide, kufuneka usathanjiswa rhoqo (iveki nganye) kwaye uqhutywe ungenanto ukuqinisekisa ukuba bhetyebhetye kwenkqubo yothumelo.

isishwankathelo

Emva kokufumana umatshini wakho we-CNC router igcisa liya kunceda ukukhupha kunye nokuhlola umatshini. Emva kokuyivula, kufuneka uhlolisise ngenyameko ukuba kukho nantoni na ebonakala yonakele ngexesha lokuthutha. Ukuba konke kulungile, khangela zonke iziqhotyoshelo zokucwangciswa komatshini ngokwekhontrakthi zikhona usebenzisa incwadana. Abachwephesha baya kufaka umatshini kubandakanywa ukufakwa kwe-hardware, ukususwa kwazo naziphi na iindawo ezisisigxina, kunye nokudibanisa kumbane. Isoftwe, uqwalaselo lwekhompyutha, kunye nayo nayiphi na isoftware yomzila we-CNC ekhethwayo nayo iya kufakwa. Ukulandela oko, ifayile yovavanyo yovavanyo enikezelwe ngumenzi iya kusetyenziswa ukuvavanya umatshini. Ukuba uvavanyo lugqityiwe ngokuchanekileyo, ukuhanjiswa kunye nokwamkelwa komatshini kugqityiwe.

Abaqhubi be-CNC kufuneka babe nesiqinisekiso semfundo yasesekondari yobugcisa okanye ngaphezulu kwaye babe nesiseko sokusebenza kwekhompyutha. Ngexesha lenkqubo yoqeqesho, baba nobuchule ekukhetheni izantya ezahlukeneyo zezinto ezahlukeneyo kunye nokusebenzisa izixhobo ezahlukeneyo ze-CNC router. Oku kudla kufuna amava abanzi kunye nobuchule babo kunceda ukwandisa ubomi oomatshini bomzila we-CNC kunye nezixhobo.

Umthombo ovela stylecnc.com

Ukuziphendulela: Ulwazi olubekwe ngasentla lunikezelwa yi-stylecnc independentiy ye-Cooig.com. I-Cooig.com ayenzi lumelo kunye neziqinisekiso malunga nomgangatho kunye nokuthembeka komthengisi kunye neemveliso.