Ngo-2025, imakethi yediski yokusila ikhonkrithi isetelwe ukuba ivele ngenkqubela phambili yetekhnoloji entsha kunye neendlela ezilungele indalo. Eli nqaku libonelela ngohlalutyo olunzulu lwemarike, iintlobo zeediski, kunye neendlela zokhetho ezibalulekileyo, ezinikezela ngengqiqo exabisekileyo kubathengi abaziingcali ukuba benze izigqibo ezinolwazi.

Isiqulatho:

– Ukuqonda iMarike yeConcrete Grinder Disc

-Iintlobo ezahlukeneyo zeeDiskhi zokuSila zekhonkrithi

-Iizinto ekufuneka ziqwalaselwe xa ukhetha i-Concrete Grinder Discs

-Ukugcinwa njani kunye nokuTshintsha iiDiss zokuSila zekhonkrithi

-IiNzuzo zokuSebenzisa iiDiskhi zokuSila zekhonkrithi ezikwiMgangatho oPhezulu

-Iingcinga zokuGqibela ekuKhetheni iiDiskhi zeSigri zeKhonkrese

Ukuqonda iMarket Grinder Disc Market

Abadlali abaphambili kuShishino lweDiskhi yeConcrete Grinder

Imakethi yediskhi yokusila ikhonkrithi ilawulwa ngabadlali abaphambili abaliqela abazimise ngokwenza izinto ezintsha kunye nomgangatho. Iinkampani ezifana ne-3M Company, Carborundum Universal Ltd., kunye ne-NORITAKE Co., Ltd. Ezi nkampani zinobukho obubalulekileyo kwintengiso kuzo zonke iindawo ezahlukeneyo, kubandakanya i-US, i-China kunye neYurophu. Ngokomzekelo, iNkampani ye-3M ibihamba phambili ekuphuhliseni iidiski zokugaya ezisebenza kakuhle ezijongene neemfuno zamashishini okwakha kunye nokuvelisa.

Ukongeza kwezi zigebenga, abanye abadlali abaphawulekayo baquka i-Camel Grinding Wheels Works Sarid Ltd. kunye ne-DEERFOS Co., Ltd. Ezi nkampani ziye zagxila ekwandiseni iiphothifoliyo zabo zemveliso ukubandakanya uluhlu olubanzi lweediski zokusila ezifanelekileyo kwizicelo ezahlukeneyo. Imbonakalo-mhlaba ekhuphisanayo iphawulwa kukuqamba izinto ezintsha okuqhubekayo, kunye neenkampani ezityala imali eninzi kuphando nakuphuhliso ukunyusa ukusebenza kunye nokuqina kweemveliso zazo. Ngokomzekelo, i-NORITAKE Co., Ltd. iye yaphuhlisa amavili okusila enziwe ngokwezifiso ezilungiselelwe usetyenziso oluthile, okwenza iziphumo eziphezulu kunye nexesha elincinane kunye nenkunkuma yezinto eziphathekayo.

Imarike ikwangqina ukungena kwabadlali abatsha abasebenzisa itekhnoloji ephezulu ukuze bafumane ukhuphiswano. Iinkampani ezifana ne-DSA Products Ltd. kunye ne-Kure Grinding Wheel zenza inkqubela ebonakalayo ngokuzisa iimveliso ezintsha ezihlangabezana neemfuno eziguqukayo zeshishini. Aba bangeneli batsha bagxile kwiimarike ze-niche kunye nezicelo ezikhethekileyo, ngaloo ndlela bedala indawo yemarike eyahlukeneyo kunye nokhuphiswano.

Imfuno yeMarike kunye neeMpawu

Imfuno yeediski zokusila zekhonkrithi iqhutywa ziindlela ezininzi eziphambili zentengiso, kubandakanywa ukonyuka kokugxila kwimveliso echanekileyo kunye nokukhula koshishino lokwakha. Imakethi yehlabathi jikelele yamavili okusila, ebandakanya iidiski zokugaya ikhonkrithi, yayimalunga needola ezingama-20.7 eebhiliyoni ngo-2023 kwaye kuqikelelwa ukuba iya kufikelela kwi-25.0 yeebhiliyoni zeedola ngo-2030, ikhula kwi-CAGR ye-2.8%. Oku kukhula kubalelwa kukukhula kwemfuno yomgangatho ophezulu kunye neemveliso ezigqitywe kakuhle kumashishini ahlukeneyo, kubandakanya iimoto, i-aerospace, kunye nokwakha.

Inkqubela phambili yezobuchwephesha nayo idlala indima ebalulekileyo ekubumbeni urhwebo. Ukuveliswa kwezinto ezintsha, ezifana nedayimane kunye ne-cubic boron nitride (CBN), ziphucula amandla okusika iidiski zokugaya, ezivumela ukuba zisebenze kwizinto ezinzima ngokuchaneka okukhulu. Inkqubela phambili kwitekhnoloji ye-bonding yandisa ixesha lokuphila kweediski zokusila, ukunciphisa ukuguga kunye nokukrazula, kunye nokwandisa ukusebenza kwabo kwisantya esiphezulu kunye nomsebenzi onzima wokusila. Le nkqubela phambili yetekhnoloji iqhuba ukwamkelwa kweediski zokusila eziphambili kuwo wonke amashishini ahlukeneyo, ukuxhasa ukukhula kwemarike.

Omnye umkhwa obalulekileyo kukwanda kokwamkelwa kwezisombululo zokusila ezihambelana nokusingqongileyo. Abavelisi bajolise ekuphuhliseni iidiski zokugaya ezivelisa uthuli oluncinci kunye nengxolo, ngaloo ndlela ukunciphisa impembelelo yendalo kunye nokuphucula ukhuseleko lomsebenzi. Lo mkhwa ubonakala ngakumbi kwimimandla enemithetho engqongqo yokusingqongileyo, njengeYurophu noMntla Merika. Ugxininiso oluqhubekayo lokuzinza kunye nokukhuselwa kwendalo kulindeleke ukuba kuqhube imfuno yeediski zokugaya i-eco-friendly kwiminyaka ezayo.

Iindidi ezahlukeneyo zeeDiskhi zokuSila zekhonkrithi

Iidiski zedayimani

Iidiski zedayimani ziphakathi kwezona ntlobo zidumileyo zeediski zokusila zekhonkrithi ngenxa yobuchule bazo bokusika obuphezulu kunye nokuqina. Ezi diski zifakwe ngamasuntswana edayimane, ezibonelela ngobulukhuni obukhethekileyo kunye nokumelana nokunxiba. Iidiski zedayimani zilungele ukusika kunye nokusila izinto eziqinileyo ezifana nekhonkrithi, igranite, kunye nebhastile. Zisetyenziswa ngokubanzi kwiiprojekthi zokwakha kunye nokuhlaziya apho ukuchaneka nokusebenza kakuhle kubalulekile.

Imarike yeediski zedayimani kulindeleke ukuba ikhule kakhulu, iqhutywa kukunyuka kwemfuno yezisombululo zokugaya ezikumgangatho ophezulu. Ngokwengxelo yeMarike yokuSila yamavili eGlobal, ukwamkelwa kwedayimane kunye ne-CBN abrasives kuyanda, njengoko ezi zixhobo zibonelela ngezakhono zokusika ezongezelelweyo kunye nobomi obude. Lo mkhwa ubonakala ngokukodwa kwishishini lokwakha, apho imfuno yezixhobo zokugaya ezisebenzayo nezithembekileyo zibaluleke kakhulu.

Ukongeza ekusebenzeni kwabo kokusika, iidiski zedayimani nazo ziyaziwa ngokuguquguquka kwazo. Zifumaneka kwiintlobo ezahlukeneyo zegrit kunye neentlobo zeebhondi, ezizenza zilungele uluhlu olubanzi lwezicelo. Umzekelo, iidiski zedayimani ezirhabaxa-grit zisetyenziselwa ukususwa kwezinto ezinobundlongondlongo, ngelixa ii-fine-grit discs zisetyenziselwa ukupolisha nokugqiba. Oku kuguquguquka kwenza iidiski zedayimani zibe yinto ekhethwayo kwiingcali kumashishini okwakha kunye nokuvelisa.

Iidiski zeSilicon Carbide

Iidiski ze-silicon ze-carbide zolunye uhlobo oludumileyo lwe-concrete grinder disc, eyaziwa ngokuba lukhuni kunye nobukhali. Ezi diski zenziwe kwi-silicon carbide, izinto zokwenziwa ezibonelela ngokugqwesileyo kokusika kunye nokuqina. Iidiski ze-silicon ze-carbide ziqhele ukusetyenziselwa ukugaya kunye nokusika izinto ezithambileyo ezifana nekhonkrithi, i-masonry, kunye nelitye. Zikwasetyenziselwa ukulungiswa komphezulu kunye nokugqiba izicelo.

Imarike yeediski ze-silicon carbide iqhutywa yimfuno ekhulayo yezisombululo zokusila ezingabizi kakhulu. I-silicon carbide ayibizi kakhulu xa ithelekiswa nedayimane, iyenza ibe lukhetho olunomtsalane kubathengi abajonga uhlahlo lwabiwo-mali. Ngokwengxelo yeMarike yokuSila ye-Global Grinding Wheels, imfuno yeediski ze-silicon carbide kulindeleke ukuba ikhule ngokuthe chu, ixhaswa kukukhula kwemisebenzi yokwakha kunye neeprojekthi zophuhliso lweziseko zophuhliso kwihlabathi liphela.

Iidiski ze-Silicon carbide ziyafumaneka kwiisayizi ezahlukeneyo zegrit kunye noqwalaselo, okuvumela abasebenzisi ukuba bakhethe idiski elungileyo kwiimfuno zabo ezithile. Umzekelo, i-coarse-grit silicon carbide discs isetyenziselwa ukususwa kwezinto ezinzima, ngelixa iidiski ze-fine-grit zisetyenziselwa ukupolisha nokugqiba. Ubukho bobukhulu obahlukeneyo begrit kunye noqwalaselo kwenza iidiskhi zesilicon carbide zibe yinketho eguquguqukayo kunye neendleko ezisebenzayo kwiinkqubo ezahlukeneyo zokusila.

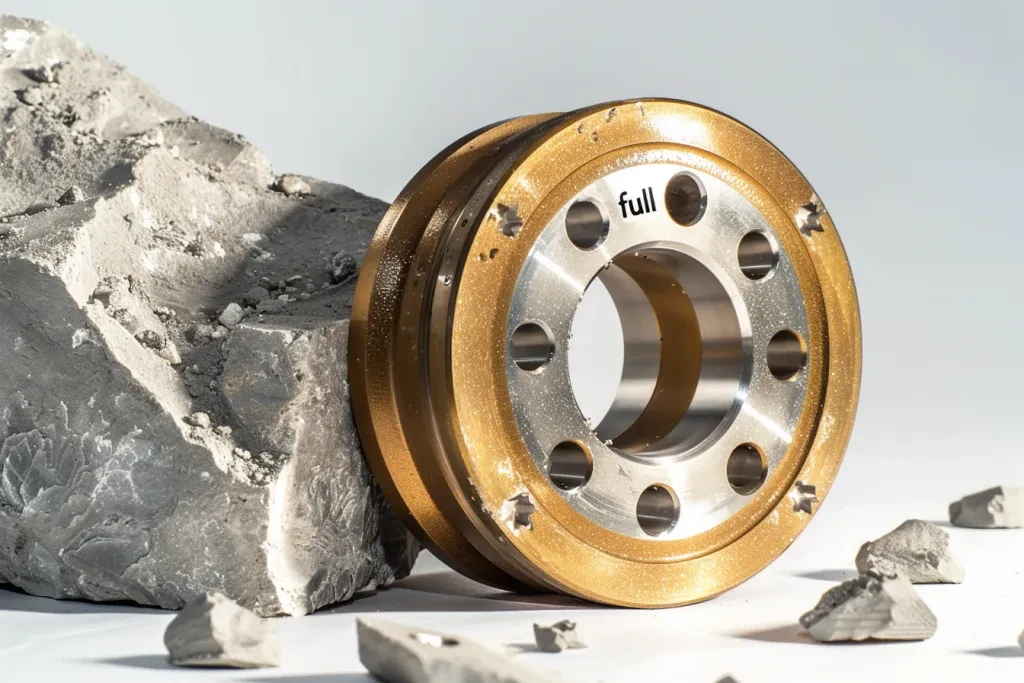

Iidiski zeTungsten Carbide

Iidiski ze-tungsten carbide zaziwa ngobunzima bazo obukhethekileyo kunye nokunganyangeki kokunxiba, okubenza ukuba balungele usetyenziso olunzima lokugaya. Ezi diski zenziwe kwi-tungsten carbide, into enzima kakhulu kunentsimbi kwaye inika umsebenzi obalaseleyo wokusika. Iidiski zeTungsten carbide ziqhele ukusetyenziselwa ukugaya kunye nokusika izinto eziqinileyo ezifana nekhonkrithi, isinyithi, kunye neeseramics.

Imarike yeediski ze-tungsten carbide kulindeleke ukuba ikhule, iqhutywa kukunyuka kwemfuno yezixhobo zokugaya ezisebenza kakhulu kumashishini ahlukeneyo. Ngokwengxelo yeMarike yokuGla yamavili eGlobal, ukwamkelwa kwezixhobo zokugrumba eziphambili ezifana ne-tungsten carbide kuyanda, njengoko ezi zixhobo zibonelela ngezakhono zokusika eziphezulu kunye nobomi obude. Lo mkhwa ubonakala ngokukodwa kumashishini okwenza isinyithi kunye nokwakhiwa, apho imfuno yezixhobo zokusila ezihlala ixesha elide kunye nezisebenzayo zibalulekile.

Iidiski ze-Tungsten carbide zifumaneka kwiisayizi ezahlukeneyo zegrit kunye neentlobo zebhondi, zibenza zilungele uluhlu olubanzi lwezicelo. Ngokomzekelo, ii-coarse-grit tungsten carbide discs zisetyenziselwa ukususwa kwezinto ezinobundlobongela, ngelixa ii-fine-grit discs zisetyenziselwa ukupolisha nokugqiba. Ukuguquguquka kunye nokuqina kweediski ze-tungsten carbide kuzenza zibe lukhetho olukhethwayo kwiingcali kulwakhiwo, ukusebenza kwesinyithi, kunye nokuvelisa.

Izinto ekufuneka ziqwalaselwe xa ukhetha i-Concrete Grinder Discs

Ubulukhuni bezinto eziphathekayo

Ubulukhuni bezinto eziphathekayo yinto ebalulekileyo ekufuneka iqwalaselwe xa ukhetha iidiski zokusila eziphathekayo. Ubunzima bezinto eziphantsi komhlaba bumisela uhlobo lwezinto ezinqabileyo ezimele zisetyenziswe. Umzekelo, iidiski zedayimani zilungele ukugaya izinto ezinzima ezifana nekhonkrithi kunye negranite, ngelixa iidiski ze-silicon carbide zifanelekile kwizinto ezithambileyo ezifana ne-masonry kunye nelitye. Ngokwengxelo ye-Global Grinding Wheels Market, ukwamkelwa kwezinto eziphucukileyo ezinje ngedayimani kunye ne-CBN kuyanda, kuqhutywa yimfuneko yezisombululo ezisebenzayo nezithembekileyo zokusila.

Ukuqina kwediski yokugaya ngokwayo kubalulekile, njengoko kuchaphazela ukuqina kunye nokusebenza kwediski. Iidiski ezinzima, ezifana nezo zenziwe ngedayimane kunye ne-tungsten carbide, zibonelela ngokumelana nokunxiba okuphezulu kunye nobomi obude, okubenza bafanelekele izicelo zokugaya. Ngakolunye uhlangothi, iidiski ezithambileyo, ezifana nezo zenziwe kwi-silicon carbide, zixabisa ngakumbi kwaye zifanelekile kwimisebenzi yokusila elula. Ukuqonda ubulukhuni bezinto zombini ezisemhlabeni kunye nediski yokusila kubalulekile ekukhetheni idiski efanelekileyo yomsebenzi.

Ukongeza kubulukhuni bezinto eziphathekayo, ezinye izinto ezifana nohlobo lwebhondi kunye nobukhulu begrit kufuneka ziqwalaselwe. Uhlobo lwebhondi luchaphazela ukusebenza kwe-disc yokusika kunye nokuqina, ngelixa ubungakanani begrit bumisela inqanaba lokususwa kwezinto kunye nokugqiba umphezulu. Ngokuqwalasela le miba, abasebenzisi banokukhetha idiski yokusila echanekileyo ehlangabezana neemfuno zabo ezithile kwaye iqinisekisa ukusebenza kakuhle kunye nokusebenza kakuhle.

Ubungakanani beDisc Grit

Ubungakanani begrit yediskhi yenye into ebalulekileyo ekufuneka uyiqwalasele xa ukhetha iidiski zokusila zekhonkrithi. Ubungakanani begrit bubhekisela kubukhulu beengqungquthela ezinqabileyo kwi-disc, emisela inqanaba lokususwa kwezinto kunye nokugqiba umgangatho. Iidiski ze-coarse-grit, ezinamasuntswana amakhulu abrasive, zisetyenziselwa ukususwa kwezinto ezinobundlobongela kunye nokusila ngokukrakra, ngelixa i-fine-grit discs, enamancinci amancinci amancinci, asetyenziselwa ukupolisha nokugqiba.

Ukukhethwa kobukhulu begrit kuxhomekeke kwisicelo esithile kunye nokugqiba okufunwayo kwendawo. Umzekelo, ii-coarse-grit discs zifanelekile ekususeni iileya ezishinyeneyo zemathiriyeli, njengepeyinti endala okanye iicoatings, ngelixa ii-fine-grit discs zisetyenziselwa ukufikelela umphezulu ogudileyo kunye nopolishiwe. Ngokwengxelo ye-Global Grinding Wheels Market, imfuno yeediski zokugaya ezikumgangatho ophezulu kunye nobukhulu obahlukeneyo begrit iyanyuka, iqhutywa yimfuneko yokuchaneka kunye nokusebenza kakuhle kumashishini ahlukeneyo.

Ukongeza kubungakanani begrit, uhlobo lwezinto ezirhabaxa kunye nohlobo lwebhondi nalo ludlala indima ebalulekileyo ekumiseleni ukusebenza kwediski. Umzekelo, iidiski zedayimani ezinobungakanani begrit entle zisetyenziselwa ukupolisha izinto eziqinileyo ezifana negranite kunye nebhastile, ngelixa iidiski zesilicon carbide ezinobungakanani begrit erhabaxa zisetyenziselwa ukucola izinto ezithambileyo ezifana nekhonkrithi kunye nelitye. Ngokuqwalasela ubungakanani begrit, i-abrasive material, kunye nohlobo lwebhondi, abasebenzisi banokukhetha i-disc ye-grinder efanelekileyo ehlangabezana neemfuno zabo ezithile kwaye iqinisekisa ukusebenza kakuhle kunye nokusebenza kakuhle.

Uhlobo lweDisc Bond

Uhlobo lwebhondi yediski ye-grinder yekhonkrithi yinto ebalulekileyo echaphazela ukusebenza kwayo kunye nokuqina. Uhlobo lwebhondi lubhekisela kwizinto ezibamba amaqhekeza abrasive ndawonye kwidiski. Iindidi zeebhondi eziqhelekileyo ziquka i-resin, isinyithi, kunye neebhondi eziqinisekisiweyo, nganye inika amanqanaba ahlukeneyo okusebenza kunye nokuqina. Ngokomzekelo, iibhondi ze-resin zibonelela ngokuguquguqukayo kwaye zifanelekile ukugaya injongo jikelele, ngelixa iibhondi zetsimbi zinika ukuqina okuphezulu kwaye zilungele izicelo zokugaya.

Ukukhethwa kohlobo lwebhondi kuxhomekeke kwisicelo esithile kunye nezinto eziphathekayo. Ngokomzekelo, iidiski eziboshwe nge-resin ziqhelekileyo zisetyenziselwa ukugaya izinto ezithambileyo ezifana nekhonkrithi kunye ne-masonry, ngelixa iidiski eziboshiweyo zetsimbi zisetyenziselwa ukugaya izinto ezinzima ezifana negranite kunye nentsimbi. Ngokwengxelo ye-Global Grinding Wheels Market, imfuno yobuchwepheshe obuphezulu bokudibanisa inyuka, iqhutywa yimfuneko yokusebenza okuphezulu kunye nezisombululo zokugaya ezizinzileyo.

Ukongeza kuhlobo lwebhondi, ezinye izinto ezifana nobukhulu begrit kunye nezinto ezixubekileyo kufuneka ziqwalaselwe. Ukudityaniswa kwezi zinto kumisela ukusebenza kwediski, ukuqina, kunye nokusebenza kakuhle. Ngokukhetha uhlobo oluchanekileyo lwebhondi, abasebenzisi banokuqinisekisa ukuba idiski yokugaya ihlangabezana neemfuno zabo ezithile kwaye ibonelela ngokusebenza ngokufanelekileyo kunye nokuphila ixesha elide.

Ukuhambelana ne-Grinder

Ukuhambelana negrinder yenye into ebalulekileyo ekufuneka iqwalaselwe xa ukhetha iidiski zokugaya ikhonkrithi. Idiski yokugaya kufuneka ihambelane nohlobo oluthile kunye nomzekelo wegrinder esetyenziswayo. Oku kubandakanya izinto ezifana nobukhulu bediski, ubungakanani be-arbor, kunye nesantya esiphezulu sokusebenza. Ukusebenzisa i-disc engahambelaniyo kunokubangela ukusebenza kakubi, umonakalo kwi-grinder, kunye nobungozi obunokhuseleko.

Ubungakanani bediskhi bubhekisa kububanzi bediski yokusila, ekufuneka ihambelane nobukhulu bomlindi wevili losila. Ubungakanani bediski eziqhelekileyo ziquka i-intshi ye-4.5, i-intshi ye-7, kunye ne-intshi ezi-9, kunye neediski ezinkulu ezisetyenziselwa ukugaya izicelo ezinzima. Ubungakanani be-arbor bubhekiselele kububanzi bomngxuma osembindini wediski, ekufuneka ihambelane nobukhulu be-spindle ye-grinder. Ubungakanani obuqhelekileyo be-arbor bubandakanya i-intshi ye-5/8 kunye ne-7/8 intshi.

Isantya esiphezulu sokusebenza kwediski ye-grinder kufuneka kwakhona ihambelane nesantya sokulinganisa i-grinder. Ukusebenzisa i-disc enesantya esisezantsi kunokulinganisa i-grinder kunokubangela ukungaphumeleli kwediski kunye neengozi ezinokuthi zikhuseleke. Ngokuqinisekisa ukuhambelana negrinder, abasebenzisi banokuqinisekisa ukusebenza kakuhle, ukhuseleko kunye nokusebenza kakuhle.

Iindleko kunye nohlahlo lwabiwo-mali

Iindleko kunye nohlahlo lwabiwo-mali zizinto ezibalulekileyo zokuqwalaselwa xa ukhetha iidiski zokusila eziphathekayo. Iindleko zeediski zokusila zinokwahluka kakhulu ngokuxhomekeke kwizinto ezifana nohlobo lwezinto eziqhumayo, uhlobo lwebhondi, ubungakanani begrit, kunye nophawu. Ngokomzekelo, iidiski zedayimani zihlala zibiza kakhulu kunee-silicon carbide discs ngenxa yokusebenza kwazo okuphezulu kunye nokuqina. Nangona kunjalo, ixabiso eliphezulu leediski zedayimani zinokuthetheleleka kubomi bazo obude kunye nokunciphisa isidingo sokutshintshwa rhoqo.

Xa uqwalasela iindleko kunye nohlahlo lwabiwo-mali, kubalulekile ukulinganisela iindleko zokuqala zediski yokugaya kunye nokusebenza kwayo kunye nokuphila ixesha elide. Utyalo-mali kwiidiski zokucoca ezikumgangatho ophezulu kunokubangela ukonga iindleko kwixesha elide ngokunciphisa imfuno yokutshintshwa rhoqo kunye nokuphucula ukusebenza kakuhle. Ngokwengxelo ye-Global Grinding Wheels Market, imfuno yokusebenza okuphezulu kunye nezisombululo zokusila ezixabisa kakhulu zinyuka, ziqhutywa yimfuneko yokuphucula imveliso kunye nokunciphisa iindleko zokusebenza.

Ukongeza kwindleko yediski yokugaya, ezinye izinto ezifana nesicelo esithile, izinto eziphantsi komhlaba, kunye nokugqiba okufunwayo kufuneka kuthathelwe ingqalelo. Ngokuphonononga ngononophelo le miba, abasebenzisi banokukhetha idiski yokusila echanekileyo ehlangabezana neemfuno zabo ezithile kwaye ibonelela ngexabiso elifanelekileyo lohlahlo lwabiwo-mali lwabo.

Uzigcina njani kwaye ubeke endaweni yazo iiDiskhi zokuSila zekhonkrithi

Iindlela zokucoca ezizizo

Ukucocwa ngokufanelekileyo kweediski ze-grinder zekhonkrithi kubalulekile ekugcineni ukusebenza kwazo kunye nokuphila ixesha elide. Qala ngokuqhawula igrinder kumthombo wamandla ukuqinisekisa ukhuseleko. Sebenzisa ibrashi yocingo okanye isixhobo esikhethekileyo sokucoca ukususa nayiphi na inkunkuma okanye i-buildup kumphezulu wediski. Ukucoca ngokucokisekileyo, cinga ukusebenzisa isisombululo esithambileyo kunye nelaphu elithambileyo ukosula idiski, uqinisekise ukuba zonke iintsalela zisusiwe.

Emva kokucoca, kubalulekile ukomisa idiski ngokupheleleyo ukuthintela ukugqwala okanye ukubola. Sebenzisa ilaphu elicocekileyo, elomileyo ukosula nakuphi na ukufuma, kwaye uvumele icwecwe ukuba lome umoya xa kuyimfuneko. Ukucoca rhoqo kufuneka kwenziwe emva kokusetyenziswa ngalunye ukugcina ukusebenza kakuhle. Ukongezelela, hlola i-disc nayiphi na imiqondiso yomonakalo okanye ukugqoka ngexesha lokucoca.

Kwiidiski ezingcoliswe kakhulu, cinga ukusebenzisa isicoci sekhemikhali esenzelwe ngokukodwa izixhobo ezirhabaxa. Landela imiyalelo yomenzi ngononophelo ukunqanda ukonakalisa idiski. Ukugcinwa ngokufanelekileyo kweediski ezicociweyo kwindawo eyomileyo, engenathuli kuya kwandisa ngakumbi ubomi babo kwaye kuqinisekiswe ukuba zilungele ukusetyenziswa xa zifuneka.

Iimpawu zoKunxila kunye nokuKhalaza

Ukuchonga iimpawu zokuguga kunye nokukrazula kwiidiski zokusila zekhonkrithi kubalulekile ekugcineni imisebenzi yokusila esebenzayo. Olunye uphawu oluqhelekileyo lukuncipha okubonakalayo ekusebenzeni kakuhle kokugaya, oku kunokubonisa ukuba indawo enqabileyo igugile. Ukongezelela, hlola i-disc yokuqhekeka okubonakalayo, ii-chips, okanye iipatheni zokugqoka ezingalinganiyo, ezinokuthi zidibanise ingqibelelo yesakhiwo kunye nokusebenza.

Esinye isalathisi sokunxiba kubukho bokungcangcazela okungaqhelekanga okanye izandi ngexesha lokusebenza. Ezi zimpawu zingabonisa ukuba i-disc ayisalingani okanye ivelise izitenxo. Ukujonga rhoqo ubukhulu bediski kubalulekile, njengoko ukuncipha okugqithisileyo kunokukhokelela ekuqhekekeni phantsi koxinzelelo.

Ukubeka iliso kwintsebenzo yediski kunye nokuqhuba uhlolo olubonakalayo lwesiqhelo lunokunceda ukufumanisa ukuguga kwangoko. Ukutshintshwa kweediski ezigugileyo okanye ezonakalisiweyo ngokukhawuleza kuya kuthintela iingozi ezinokuthi zikhuseleke kwaye kuqinisekiswe umgangatho wokugaya. Ukugcina i-log yokusetyenziswa kwe-disc kunye neepatheni zokugqoka kunokunceda kwakhona ukuqikelela ukutshintshwa kwexesha kunye nokugcina unikezelo oluzinzileyo lweediski ezisebenzayo.

Izikhokelo zoTshintsho

Ukutshintsha iidiski zokusila zekhonkrithi kubandakanya amanyathelo amaninzi abalulekileyo okuqinisekisa ukhuseleko kunye nofakelo olufanelekileyo. Qala ngokuqhawula uqhagamshelo kwisixhobo sokusila kumthombo waso wamandla ukuthintela ukusebenza ngempazamo. Sebenzisa isixhobo esifanelekileyo, njengesitshixo okanye isipanela, ukususa i-nut yokutshixa okanye i-flange ekhusela i-disc endaweni. Susa ngononophelo idiski endala, uthathele ingqalelo ukuqhelaniswa kwayo kunye naziphi na iiwasha okanye izikhewu ezisetyenzisiweyo.

Ngaphambi kokufaka icwecwe elitsha, jonga i-spindle ye-grinder kunye ne-hardware yokunyuswa kwayo nayiphi na impawu yomonakalo okanye ukuguga. Coca la macandelo ukususa nayiphi na inkunkuma okanye intsalela enokuchaphazela ukulungelelaniswa kwediski. Beka idiski entsha kwindawo yokusonta, uqinisekise ukuba ihleli ngokuchanekileyo nangokukhuselekileyo. Phinda unamathisele i-nut yokuvala okanye i-flange, uyiqinise ngokweenkcukacha zomenzi.

Emva kokufakela, yenza uvavanyo olufutshane ukuze uqinisekise ukuba i-disc ilungelelaniswe ngokufanelekileyo kwaye ilinganisiwe. Mamela naziphi na ingxolo engaqhelekanga kwaye ujonge ukungcangcazela okugqithisileyo, okunokubonisa ukufakela okungafanelekanga. Ukutshintsha rhoqo iidiski ezigugileyo kwaye ulandele ezi zikhokelo kuya kunceda ukugcina ukusebenza kakuhle kokusila kunye nokwandisa ubomi bezixhobo zakho.

Iinzuzo zokuSebenzisa iiDiskhi zokuSila zekhonkrithi ezikwiMgangatho oPhezulu

Ukuphuculwa kweNtsebenzo

Iidiski zokusila zekhonkrithi ezikumgangatho ophezulu ziphucula kakhulu ukusebenza ngokubonelela ngobuchule obuphezulu bokusika kunye nokusila. Ezi diski ziqhele ukwenziwa ngemathiriyeli yeprimiyamu, njengedayimani yodidi lweshishini okanye iiseramikhi eziphambili, ezibonelela ngobulukhuni obukhethekileyo kunye nokuqina. Oku kubangela amazinga okususwa kwezinto ezikhawulezayo kunye neenkqubo ezisebenzayo zokugaya.

Ukwenziwa ngokuchanekileyo kweediski ezikumgangatho ophezulu kuqinisekisa ukusebenza okuhambelanayo kunye neepatheni zokugqoka ezifanayo. Oku kuhambelana kuvumela ukusebenza kakuhle kwaye kunciphisa amathuba okuhluleka kwediski ngexesha lokusetyenziswa. Ukongeza, iidiski ezikumgangatho ophezulu zihlala zibandakanya itekhnoloji yokudibanisa ephucukileyo ephucula ukusebenza kwabo kokusika kunye nobomi.

Ukusebenzisa iidiski ezikumgangatho ophezulu kwakhona kunciphisa ixesha lokuphumla elihambelana nokutshintsha rhoqo kwediski kunye nokugcinwa. Ukusebenza okuphuculweyo kunye nokuthembeka kwezi diski kunegalelo ekwandeni kwemveliso kunye nokongiwa kweendleko ngokuhamba kwexesha. Utyalo-mali kwiidiski zegrinder zekhonkrithi ezikumgangatho ophezulu sisigqibo esicwangcisiweyo esinokuvelisa inzuzo ebalulekileyo ekusebenzeni kunye nokusebenza kakuhle.

Ukwanda kwexesha elide

Ubomi obude beediski zokugaya ikhonkrithi buphuculwe kakhulu xa usebenzisa iimveliso ezikumgangatho ophezulu. Ezi diski zenzelwe ukumelana nobunzima bezicelo zokugaya, ezinikezela ubomi obude benkonzo xa kuthelekiswa neediski eziqhelekileyo. Ukusetyenziswa kwezixhobo eziphezulu ze-abrasive kunye nobuchule obuphezulu bokubambisana buqinisekisa ukuba ii-discs eziphezulu zigcina i-cut cut yazo ixesha elide.

Ukunyuka kwexesha elide kuguqulela kutshintsho olumbalwa kunye nokuncipha kweendleko zokusebenza. Iidiski ezikumgangatho ophezulu aziqhelekanga ukunxitywa kwangaphambi kwexesha kunye nomonakalo, okuthetha ukuba ziyakwazi ukusingatha imijikelo yokusila ngaphambi kokuba ifune ukutshintshwa. Oku kuhlala kunenzuzo ngokukodwa kwiindawo ezibango apho ukusebenza okufanayo kubalulekile.

Ngaphezu koko, ubomi obandisiweyo beediski ezikumgangatho ophezulu bunegalelo ekusebenzeni kakuhle kwezixhobo ngokubanzi. Abaqhubi banokuthembela kwezi diski ukuba ziqhube ngokuqhubekayo ngaphandle kwesidingo sohlengahlengiso rhoqo okanye ukutshintshwa. Oku kuthembeka kwandisa ukuqhubeka komsebenzi kwaye kunciphisa amathuba okunciphisa ixesha elingalindelekanga, ekugqibeleni kuphuculwe amaxesha eprojekthi kunye neziphumo.

UkuGqiba komphezulu ongcono

Ukusebenzisa iidiski zokusila zekhonkrithi ezikumgangatho ophezulu kubangela ukugqitywa komphezulu ophezulu, okuyimfuneko kwiiprojekthi ezininzi zokwakha kunye nokulungiswa. Ezi diski zenzelwe ukunika ngokuchanekileyo kunye nokucola, ukunciphisa ukungafezeki komphezulu kunye nokufikelela kwisiphelo esigudileyo, esigudisiweyo. Izinto eziphezulu ze-abrasive ezisetyenziswe kula ma-discs ziqinisekisa isenzo sokusika esingaguqukiyo, ukunciphisa umngcipheko wokugaya okanye ukugaya ngokungalingani.

Ukugqitywa komgangatho ongcono akugcini nje ukwandisa isibheno sobuhle bekhonkrithi kodwa siphucula iimpawu zayo zokusebenza. Imiphezulu egudileyo kulula ukuyicoca kunye nokuyigcina, kwaye ibonelela ngokuncamathela okungcono kwiingubo kunye nezitywini. Iidiski ezikumgangatho ophezulu zisebenza ngokukodwa ekufezekiseni ukugqitywa okufanelekileyo okufunekayo kwizicelo zekhonkrithi zokuhombisa kunye nemisebenzi echanekileyo ephezulu.

Ukongezelela, ukugqitywa komgangatho ophuculweyo ophunyeziweyo ngeediski eziphezulu kunokunciphisa imfuno yamanyathelo okugqiba okongeziweyo, njengesanti okanye ukupolisha. Oku kusebenza kakuhle konga ixesha kunye neendleko zabasebenzi, okwenza inkqubo yokugaya iyonke ingabizi kakhulu. Utyalo-mali kwiidiski zokusila zekhonkrithi ezikumgangatho ophezulu lukhetho olusebenzayo lokuzuza iziphumo zebakala lobuchwephesha ngomzamo omncinci.

Iingcamango zokuGqibela ekuKhetheni iiDiskhi zokuSila zekhonkrithi

Ukukhetha iidiski zokusila zekhonkrithi ezifanelekileyo kubalulekile ekufezekiseni ukusebenza kakuhle kunye nobomi obude. Iidiski ezikumgangatho ophezulu zibonelela ngobuchule bokusika obuphuculweyo, ukomelela okwandisiweyo, kunye nokugqitywa komphezulu ongaphezulu, okubenza babe lutyalo-mali oluxabisekileyo kuso nasiphi na isicelo sokusila. Ukubeka phambili umgangatho kunye nokugcinwa okufanelekileyo kuya kuqinisekisa iziphumo ezihambelanayo kunye nokugcinwa kweendleko zexesha elide.