Ngo-2025, imakethi ye-spur gear iyaqhubeka ikhula, iqhutywa ziinguqulelo ezintsha kunye nokwanda kwemfuno kumacandelo ahlukeneyo. Eli nqaku libonelela ngohlalutyo olunzulu lwezinto eziphambili zokukhetha kubathengi abaziingcali, ukuqinisekisa olona khetho lufanelekileyo lokuphumelela kweshishini.

Isiqulatho:

-Spur Gear Market Overview

-Intshayelelo eneenkcukacha kunye nohlalutyo lweMarike yeGear ye-Spur

-Izinto eziphambili xa ukhetha i-Spur Gears

-Izicelo zeeGear ze-Spur koomatshini banamhlanje

-Ukuqhubela phambili kwi-Spur Gear Manufacturing Technologies

-Iingqwalasela zokusingqongileyo kunye noZinzo

-IiNdlela zexesha elizayo kuPhuhliso lweGear ye-Spur

-Iingcinga zokugqibela

Spur Gear Market Overview

Imakethi yehlabathi ye-spur gear ibonise ukukhula olomeleleyo kwiminyaka yakutshanje kwaye imiselwe ukuqhubeka nalo mkhwa. Ngo-2024, imakethi yayixabisa malunga ne-6.5 yeebhiliyoni zeedola kwaye kuqikelelwa ukuba ifikelele kwi-8.2 yeebhiliyoni zeedola ngo-2030, ngesantya sokukhula sonyaka (CAGR) se-4.1%. Iigiya ze-Spur zifunwa kuwo wonke amashishini ahlukeneyo afana neemoto, i-aerospace, oomatshini bemizi-mveliso, kunye neerobhothi. Icandelo leemoto libambe esona sabelo sikhulu sentengiso, kunye nezixhobo ze-spur eziqhele ukusetyenziswa kwiinkqubo zothumelo kunye neenkqubo ezahlukeneyo.

Ummandla we-Asia-Pacific ukhokela imakethi ye-spur yezixhobo zehlabathi, ibalwa ngaphezulu kwe-40% yesabelo. Olu lawulo lubangelwa kukukhula kwamacandelo eemoto nezoshishino kumazwe afana neTshayina, iJapan, neIndiya. UMntla Merika kunye neYurophu nazo zinezabelo zentengiso ezibalulekileyo, eziqhutywa yinkqubela phambili yetekhnoloji yokuvelisa kunye nobukho babavelisi abakhulu beemoto kunye noomatshini boshishino.

Intshayelelo eneenkcukacha kunye noHlahlelo lweMarike yeGear yeSpur

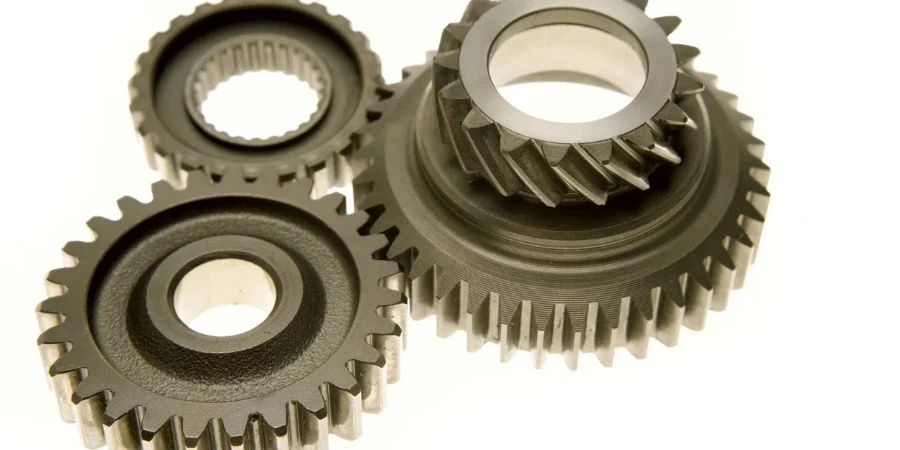

Iigiya zeSpur lolona hlobo lulula lwegiya, oluphawulwa ngamazinyo azo athe nkqo anxusene neasi yegiya. Bahambisa intshukumo kunye namandla phakathi kweeshafu ezihambelanayo, ezaziwa ngokusebenza kwazo, ukuthembeka, kunye nokukwazi ukuphatha imithwalo ephezulu yetorque. Ezi mpawu zibenza babaluleke kuthumelo lweemoto, oomatshini boshishino, kunye nerobhothi.

Iimpawu eziphambili zokusebenza ze-spur gears ziquka umthamo ophezulu wokuthwala umthwalo, ukuchaneka, ukuqina, kunye nengxolo encinci. Amandla entengiso aphenjelelwa kukunyuka kwemfuno yezixhobo zokusebenza eziphezulu kwizithuthi kunye nosetyenziso lwemizi-mveliso, ukuqhubela phambili kwimveliso yezixhobo, kunye nokusetyenziswa okukhulayo komatshini kunye neerobhothi.

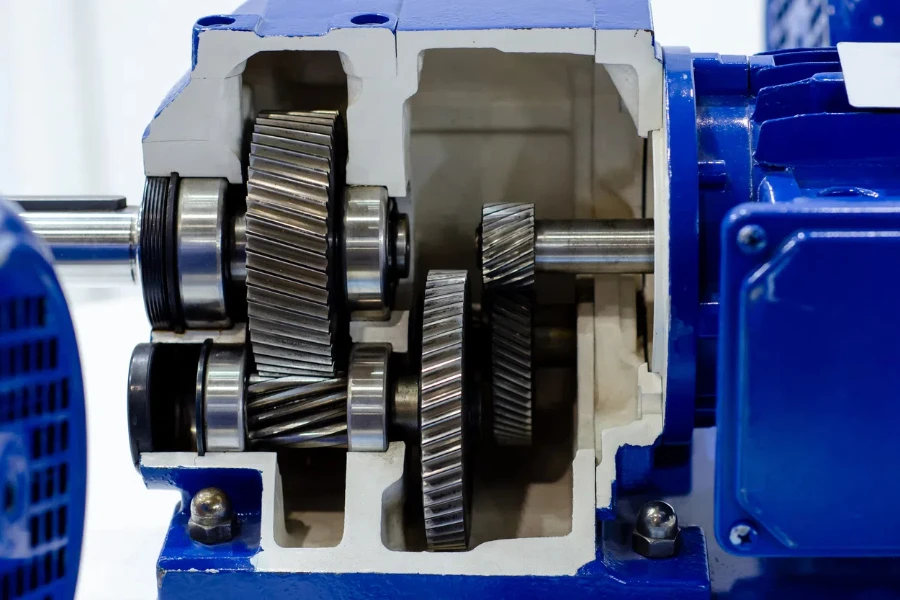

Iinguqulelo zamva nje kuyilo lwe-spur gear kunye nokuveliswa kuphucule ukusebenza. Izinto eziphucukileyo ezifana nekharbhon fibre composites kunye ne-alloys ephezulu yamandla zongeza amandla kunye nokuqina. Ubuchwephesha bedijithali obufana noyilo oluncediswa yikhompyuter (CAD) kunye nokuveliswa koncedo lwekhompyuter (CAM) kwandisa ukuchaneka kunye nokusebenza kakuhle kwimveliso yezixhobo.

Imarike yahlulwe ngohlobo lwemathiriyeli, ukusetyenziswa, kunye nommandla. Iigiya zeMetallic spur, ezenziwe ngentsimbi, ialuminiyam, kunye nobhedu, zilawula ngenxa yamandla kunye nokuqina kwazo. Iigiya ezingezizo ezentsimbi, ezenziwe ngepolycarbonate kunye nenayiloni, zizuza ukuthandwa kwizicelo apho ukunciphisa ubunzima kunye nokunciphisa ingxolo kubalulekile.

Imingeni yabathengi ibandakanya iindleko eziphezulu zezixhobo kunye nobuchwepheshe, kunye nesidingo sokugcinwa rhoqo kunye nokuthambisa. Abavelisi baphuhlisa izisombululo ezingabizi kakhulu kunye nokuphucula ukuqina kunye nokuthembeka ngokuyila okutsha kunye nokukhethwa kwezinto eziphathekayo.

Izicwangciso zokubeka uphawu kwimakethi ye-spur igxile kumgangatho, ukusebenza, kunye nokuthembeka. Abavelisi abaphambili batyala imali kuphando nakuphuhliso ukwenza izisombululo zegiya eziphuhlayo ezihlangabezana neemfuno zeshishini. Iindlela zokwahlulahlula zibandakanya izisombululo zegiya ezilungelelanisiweyo, inkxaso ebanzi emva kokuthengisa, kunye nokuxhasa itekhnoloji yedijithali ukuphucula ukusebenza kunye nokwaneliseka kwabathengi.

Iimarike ze-Niche ze-spur gears ziquka i-aerospace kunye ne-robotics, apho ukuchaneka kunye nokuthembeka kubaluleke kakhulu. Kula macandelo, iigiya ze-spur zisetyenziswa kwii-activators, iindlela zokulawula, kunye neengalo zerobhothi. Ulwamkelo olwandayo lwe-automation kunye nerobhothi kumashishini ahlukeneyo kulindeleke ukuba kuqhube imfuno yomgangatho ophezulu wokusebenza kwe-spur gears kwiminyaka ezayo.

Izinto eziphambili xa ukhetha iiGear ze-Spur

Uhlobo lwezinto

Ukuqulunqwa kwezinto eziphathekayo kubalulekile ekukhetheni izixhobo ze-spur, ukuchaphazela ukuqina, ukusebenza, kunye neendleko. Izinto eziqhelekileyo zibandakanya isinyithi, i-alloy steel, kunye neeplastiki. Intsimbi yentsimbi yomelele kwaye kulula ukuyenza, iyenza ilungele ukusetyenziswa kobunzima. Intsimbi ye-alloy inika ukuqina okuphezulu kunye nokumelana nomhlwa, ilungele indawo enokunxitywa. Iiplastiki ezifana ne-acetal kunye nenayiloni zikhaphukhaphu kwaye ziyakwazi ukumelana nomhlwa, zilungele ukusebenza okuzolileyo kunye ne-inetia esezantsi.

Imilinganiselo yeGear kunye neNgcaciso

Imilinganiselo ye-spur gear ichaphazela ngokuthe ngqo ukusebenza kwayo. Iimpawu eziphambili ziquka i-diametral pitch (DP), i-circular pitch (CP), kunye nemodyuli (M). I-Diametral pitch ibonisa inani lamazinyo nge-intshi nganye ye-pitch diameter, kunye ne-DP ephezulu ebonisa isithuba samazinyo. I-pitch yesetyhula ilinganisa umgama phakathi kwamazinyo akufutshane, ngelixa imodyuli ingumlinganiselo wemetric yobungakanani begiya. Imilinganiselo echanekileyo iqinisekisa i-meshing efanelekileyo kunye nokuhanjiswa kwamandla okufanelekileyo.

I-Angle yoxinzelelo kunye neProfayili yezinyo

I-angle yoxinzelelo, ngokuqhelekileyo i-14.5 ° okanye i-20 °, ichaphazela ukuhanjiswa komthwalo wegiya kunye nemigangatho yengxolo. I-engile yoxinzelelo ephezulu ikhokelela kumazinyo omelele akwaziyo ukuphatha imithwalo ephezulu kodwa inokonyusa ingxolo. Iprofayili yezinyo, kubandakanywa imilo ye-involute kunye ne-cycloidal, imisela ukugudiswa kunye nokusebenza kakuhle. Iiprofayili ze-involute zixhaphakile ngenxa yomlinganiselo wesantya esingaguqukiyo kunye nokulula kokwenziwa.

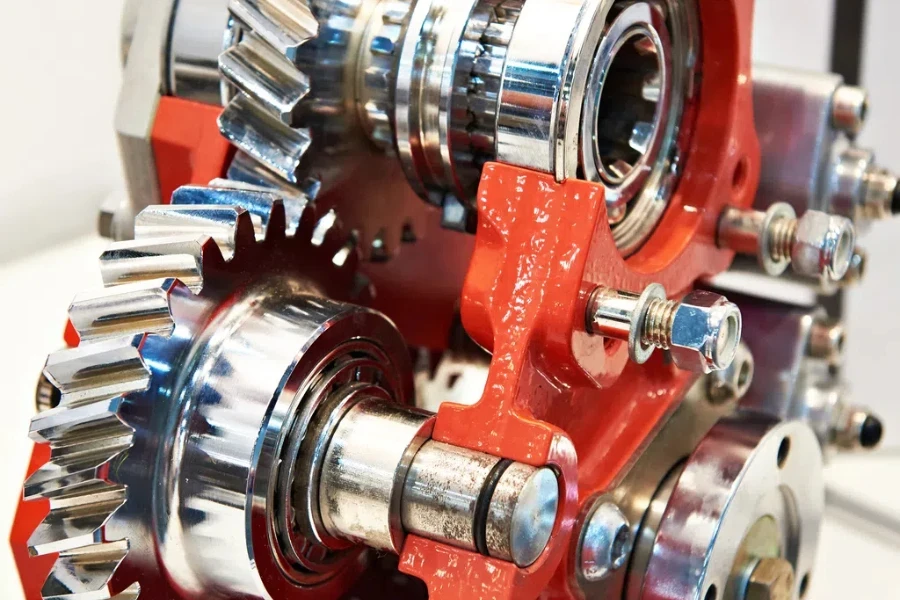

Ukunyuka kunye noLungelelwaniso lweShaft

Ukunyuswa okufanelekileyo kunye nokulungelelaniswa kwe-shaft kubalulekile ekusebenzeni okuthembekileyo kwe-spur gear. Iinketho zokukhwela ziquka ihabhu, indlela engundoqo, iseti isikrufu, kunye noyilo lokwahlulahlula. Iziko lezixhobo, i-diameter ebolekileyo, kunye nedayamitha ye-shaft kufuneka ihambelane noncamathiselo olukhuselekileyo. Ukungahambi kakuhle kunokukhokelela ekwandeni kokugqoka, ingxolo, kunye nokunciphisa ukusebenza kakuhle, kufuna ukulungelelaniswa okuchanekileyo ngexesha lofakelo.

Ukuthambisa ajikeleze kunye nolondolozo

Ukuthambisa kubalulekile ekunciphiseni ukukhuhlana, ukunxiba, kunye nokuveliswa kobushushu kwiigiya ze-spur. Uhlobo lwe-lubricant kunye ne-lubrication method, ezifana neebhafu zeoli okanye igrisi, kuxhomekeke kwindawo yokusebenza kunye neemeko zomthwalo. Ukugcinwa rhoqo, kubandakanywa ukuhlolwa kunye nokuthambisa kwakhona, kwandisa ixesha lokuphila kwesixhobo kunye nokuqinisekisa ukusebenza kakuhle. Kwiindawo ezingcolisayo okanye zobushushu obuphezulu, izithambiso ezikhethekileyo zinokufuneka ukugcina imfezeko yezixhobo.

Ukusetyenziswa kweeGear ze-Spur koomatshini banamhlanje

Iigiya ze-Spur zisetyenziswa ngokubanzi kuwo wonke amashishini ahlukeneyo ngenxa yokulula kunye nokusebenza kakuhle. Kwizicelo zeemoto, ziyimfuneko kwiinkqubo zothumelo, zibonelela ukuhanjiswa kwamandla okuthembekileyo phakathi kweeshafu ezihambelanayo. Oomatshini bemizi-mveliso, abanje ngeenkqubo zokuhambisa kunye nezixhobo zokupakisha, basebenzisa iigiya ze-spur ukuze bakwazi ukuphatha imithwalo ephezulu kunye nokubeka kwindawo echanekileyo. Ukongeza, iirobhothi kunye neenkqubo ezizenzekelayo zisebenzisa iigiya ze-spur zolawulo oluchanekileyo kunye nokunciphisa isantya.

Ukuqhubela phambili kwi-Spur Gear Manufacturing Technologies

Inkqubela phambili kwitekhnoloji yokuvelisa iphucule kakhulu umgangatho kunye nokusebenza kweegiya ze-spur. Uyilo oluncediswa yikhompyuter (i-CAD) kunye nemveliso encediswa yikhompyuter (CAM) yenza imodeli yegiya echanekileyo kunye nemveliso, ukunciphisa iimpazamo kunye nokuphucula ukusebenza kakuhle. Imveliso eyongeziweyo, okanye ushicilelo lwe-3D, luvumela ukuveliswa ngokukhawuleza kunye noyilo lwegiya yesiko, ukulungiselela iimfuno ezithile zesicelo. Izinto eziphucukileyo, kubandakanywa ii-composites kunye neeplastiki eziphezulu zokusebenza, zinika amandla aphuculweyo kunye nokuqina ngelixa unciphisa ubunzima.

Ukuqwalaselwa kokusingqongileyo kunye noZinzo

Uzinzo luya lubaluleke kakhulu ekwenzeni izixhobo. Ukusetyenziswa kwezinto ezilungele i-eco-friendly kunye ne-lubricant, kunye neenkqubo zokuvelisa amandla, kunciphisa impembelelo yokusingqongileyo kwimveliso yegiya. Ukurisayikilishwa kunye nokulungiswa kwakhona kwezixhobo zandisa umjikelo wobomi bazo, kucutha inkcitho. Abavelisi bakwaphonononga izithambisi ezinokonakala ngebhayoloji kunye nemathiriyeli ukwandisa ngakumbi uzinzo lweenkqubo zegiya.

IiNdlela zekamva kuPhuhliso lweGear ye-Spur

Ikamva lophuhliso lwe-spur gear kusenokwenzeka ukuba ligxile ekwandiseni ukusebenza kakuhle, ukuqina, kunye nokwenza ngokwezifiso. Izinto ezintsha kwisayensi yezinto eziphathekayo, ezifana nophuhliso lwama-nanomaterials kunye nee-composites eziphambili, ziya kukhokelela kwiigiya ezinamandla kunye nezilula. Ubuchwephesha bokuvelisa i-Smart, kubandakanywa ne-Intanethi yeZinto (i-IoT) kunye ne-Industry 4.0, iya kwenza ukubeka iliso ngexesha langempela kunye nokugcinwa kwangaphambili, ukuphucula ukuthembeka kwegiya kunye nokunciphisa ixesha lokuphumla. Ukwenza ngokwezifiso ngobuchule obuphezulu bokuvelisa kuya kuvumela iigiya ezilungiselelwe usetyenziso oluthile, ukwenza ngcono ukusebenza kunye nokusebenza kakuhle.

Iingcinga Final

Isishwankathelo, ukukhetha i-spur gear efanelekileyo kubandakanya ukuthathela ingqalelo izinto ezinje ngokwakhiwa kwezinto, imilinganiselo, i-angle yoxinzelelo, ukunyuswa, kunye nokuthambisa. Ukuqonda iimfuno ezithile zesicelo sakho kunye nokuhlala unolwazi malunga nenkqubela phambili yamva nje kwitekhnoloji yegiya kuya kuqinisekisa ukusebenza ngokugqibeleleyo kunye nokuphila ixesha elide. Ngokubeka phambili le miba iphambili, unokwenza izigqibo ezinolwazi ezonyusa ukusebenza kakuhle kunye nokuthembeka kweenkqubo zoomatshini bakho.