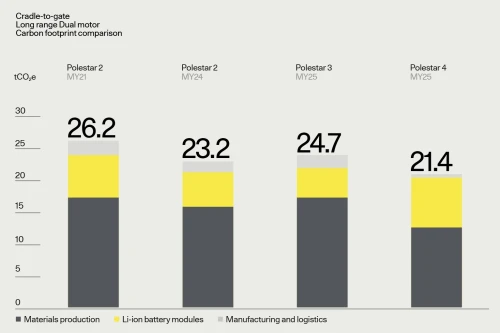

The total cradle-to-gate carbon footprint of Polestar’s first electric performance SUV, Polestar 3, is lower than that of the smaller Polestar 2 when it was launched in 2020 at 24.7 tCO2e 대 26.1tCO2e.

The majority of greenhouse gas (GHG) emissions stem from the extraction and processing of various materials for three components: aluminum, steel, and batteries. The Lifecycle Assessment (LCA) report for Polestar 3 shows that material production and refining contribute 68% of its cradle-to-gate carbon footprint of which aluminum represents 24%, iron and steel 17% and battery module production 24%.

Polestar aims to implement existing solutions, advocate for emerging solutions, and actively address what is currently considered unsolvable. Existing solutions may involve purchasing aluminum produced using renewable electricity, emerging solutions could include steel made with renewable energy, and entirely new solutions may relate to electronics, tires, and thermoplastics.

The approach to meeting the ambitious cradle-to-gate target for Polestar 3 took learnings from the carbon footprint reductions of Polestar 2. Consequently, 81% of Polestar 3’s total aluminum mass production, the Li-ion battery cell module production as well as anode and cathode material production use 100% renewable electricity. By doing this, 8.5 tCO2e는 제거되었습니다.

Manufactured initially at Volvo Cars’ Chengdu factory in China, additional production is slated to start in South Carolina in the middle of 2024. Both manufacturing plants use 100% renewable electricity. A separate LCA will be produced for cars produced in this factory.

The majority of a vehicle’s greenhouse gas emissions stem from extracting and processing materials. As we accelerate the adoption of electric cars, there is a lot we can do to reduce their production-related emissions and strengthen the role of innovations and of electric cars as a climate solution, Polestar 3 is a testament to that.

—Fredrika Klarén, Head of Sustainability at Polestar

Comprehensive transparency about the environmental impact of the car is offered by the LCA report. The LCA has been calculated using three different electricity mixes and a 200,000 km lifetime distance driven. The methodology to assess the electricity in use phase has been updated and now includes more realistic scenarios from the IEA (International Energy Agency) which take into account increased shares of renewables, underscoring their potential for reducing the car’s emissions during the use phase.

For the first time in any Polestar LCA, vehicle maintenance is included in the calculations. The car’s cradle-to-grave carbon footprint ranges between 28.5 – 44.5 tCO2e 차량 수명 동안 차량을 충전하는 데 사용되는 전기에 따라 달라집니다.

ISO 14067:2018에 따라 수행된 LCA 보고서는 제XNUMX자, 즉 글로벌 전략, 환경 및 엔지니어링 컨설팅 회사인 Ricardo plc가 검토한 최초의 Polestar LCA 보고서입니다.

출처 녹색 자동차 의회

면책조항: 위에 명시된 정보는 Cooig.com과 별개로 greencarcongress.com에서 제공한 것입니다. Cooig.com은 판매자와 제품의 품질과 신뢰성에 대해 어떠한 진술이나 보증도 하지 않습니다.