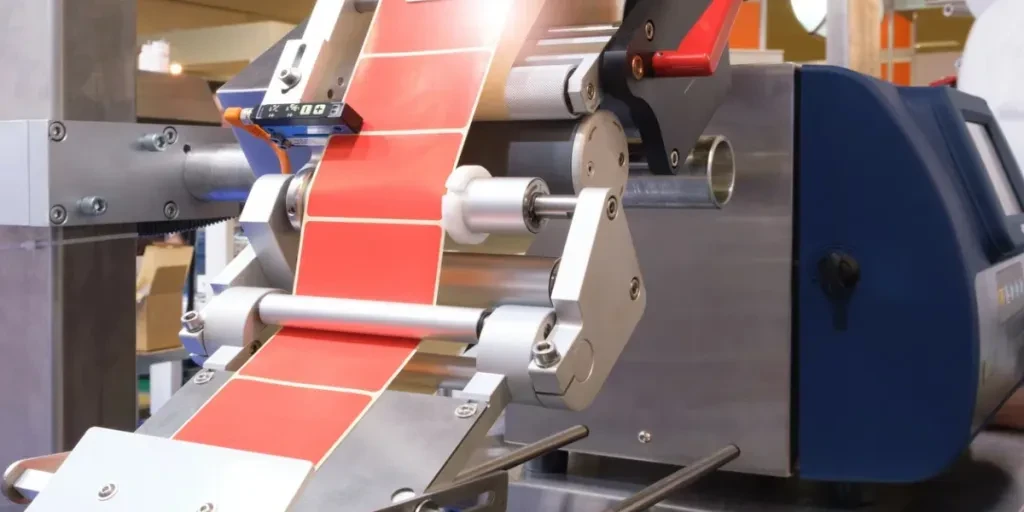

The demand for sticker maker machines has surged in 2025, driven by innovations and the expanding e-commerce sector. This article delves into an in-depth analysis of market trends, performance benchmarks, and the latest technological advancements. Professional buyers will find valuable insights to make informed decisions, ensuring optimal performance and quality in their sticker production operations.

Table of Contents:

– Market Overview of Sticker Maker Machine

– Detailed Analysis of the Sticker Maker Machine Market

– Key Factors When Selecting a Sticker Maker Machine

– Latest Technology Features in Sticker Maker Machines

– Regulatory Compliance and Certifications

– Ease of Use and Initial Setup Complexity

– Conclusion

Market Overview of Sticker Maker Machine

The global sticker maker machine market has experienced significant growth due to the increasing demand for customized and on-demand printing solutions. The market size reached approximately USD 2.5 billion in 2024, with a projected growth rate of 6.5% CAGR up to 2029. The surge in e-commerce activities and the need for efficient packaging and labeling solutions have been primary factors contributing to this growth. The rise of online retail has necessitated high-quality, quick-turnaround label printing, further fueling market expansion.

North America holds the largest market share, accounting for approximately 35% of the global market. This dominance is attributed to the region’s robust e-commerce sector and technological advancements in printing solutions. Europe follows closely with a 28% market share, driven by the demand for sustainable and eco-friendly labeling solutions. The Asia-Pacific region is expected to exhibit the highest growth rate, propelled by the expanding retail sector and increasing investment in digital printing technologies.

In terms of product segments, the vinyl sticker segment dominates, holding a 40% share of the market. Vinyl’s durability and versatility make it a preferred choice for various applications, including product labeling, branding, and promotional materials. The roll labels segment also shows significant growth, primarily due to its compatibility with automatic labeling machines and cost-effectiveness for bulk printing.

Detailed Analysis of the Sticker Maker Machine Market

The sticker maker machine market has undergone significant transformations, characterized by technological advancements, consumer behavior shifts, and evolving industry demands. Key performance benchmarks in the market include print speed, resolution, and material compatibility. Modern sticker makers can achieve print speeds of up to 14 inches per second, with resolutions as high as 1200 dpi, ensuring high-quality output suitable for intricate designs and vibrant colors.

Market share dynamics reveal a competitive landscape with major players such as Brother Industries, Canon, and Zebra Technologies leading the market. These companies have leveraged technological innovations, such as mobile printing capabilities and cloud-based solutions, to enhance their product offerings. The integration of wireless connectivity options has also played a crucial role in meeting the needs of remote work and mobile operations.

Economic influences, such as the growth of the e-commerce sector, have significantly boosted the demand for sticker maker machines. The need for efficient and accurate labeling solutions in logistics and inventory management has driven businesses to invest in advanced sticker makers. Additionally, regulatory requirements in industries like healthcare and pharmaceuticals, which mandate tamper-evident labels and serialization capabilities, have further propelled market growth.

Consumer behavior shifts towards personalized and customized products have led to an increased demand for sticker makers capable of on-demand printing. This trend is particularly evident in the retail and food and beverage industries, where businesses seek to differentiate their products through unique and eye-catching labels. Digitalization has also played a pivotal role, with the adoption of digital label printing solutions offering cost-effectiveness and flexibility.

Recent innovations in the market include the development of eco-friendly and sustainable printing solutions. Sticker makers that use biodegradable materials and eco-inks are gaining traction, aligning with the growing environmental consciousness among consumers and businesses. This shift towards sustainability not only addresses regulatory requirements but also enhances brand reputation and customer loyalty.

Despite the market’s growth, challenges such as intense competition and price pressure persist. Smaller and newer entrants often struggle to compete with established companies that offer cost-effective solutions. Additionally, rapid technological advancements necessitate continuous investment in research and development, posing a challenge for smaller players. Supply chain disruptions, such as those experienced during the COVID-19 pandemic, have also highlighted the need for resilient and stable supply chains.

Key Factors When Selecting a Sticker Maker Machine

Choosing the right sticker maker machine is crucial for ensuring optimal performance, quality, and efficiency. Here, we delve into the most critical factors to consider, offering a comprehensive guide to help you make an informed decision.

Types and Styles

Sticker maker machines come in various types and styles, tailored to different applications and user needs. Desktop sticker makers are perfect for small-scale operations, offering ease of use and portability. These machines typically handle limited volumes and are ideal for crafting, small businesses, or home use. Industrial sticker makers cater to larger-scale operations, providing higher output and robust performance.

For industrial applications, automated sticker maker machines are a prime choice. These machines can handle high volumes with minimal operator intervention, enhancing productivity. They often come with advanced features like automatic feed and cut functions, reducing manual labor and the potential for errors. Semi-automatic machines strike a balance between manual and automated operations, offering flexibility for medium-scale production.

Performance and Functionality

Performance is a critical aspect when selecting a sticker maker machine. Key performance indicators include the speed of operation, precision of cuts, and the range of materials the machine can handle. High-speed machines are essential for large production runs, significantly reducing processing time. Precision is equally important, especially for intricate designs, ensuring clean and accurate cuts.

Functionality extends to the machine’s ability to handle various materials. Versatile sticker makers can process different types of adhesive-backed paper, vinyl, and other substrates, providing flexibility in sticker production. Additionally, features like die-cutting, kiss-cutting, and perforating capabilities can enhance the machine’s functionality, allowing for diverse sticker types.

Technical Specifications

Understanding the technical specifications of sticker maker machines is essential for aligning the machine’s capabilities with your production needs. Specifications such as cutting width, cutting force, and resolution are pivotal. Cutting width determines the maximum size of stickers that can be produced, with wider machines catering to larger formats.

Cutting force, measured in grams, indicates the machine’s ability to handle thicker materials. Higher cutting force is necessary for robust materials like vinyl or laminated paper. Resolution, typically measured in dots per inch (dpi), affects the detail and clarity of the cuts. Higher resolution machines produce finer and more detailed stickers, which is crucial for intricate designs and high-quality outputs.

Price Range and Budget

Price is often a decisive factor when selecting a sticker maker machine. It is important to balance cost with the features and performance required for your specific needs. Entry-level machines are more affordable and suitable for personal or small business use, offering essential functions at a lower cost. Mid-range machines provide a good mix of performance and features, catering to medium-scale production needs without a hefty price tag.

For large-scale industrial applications, investing in high-end machines can be justified by the advanced features, higher speeds, and greater durability they offer. While the initial investment may be higher, the long-term benefits in terms of productivity and quality can outweigh the costs. Considering the total cost of ownership, including maintenance and operational costs, can provide a clearer picture of the machine’s affordability.

Latest Technology Features in Sticker Maker Machines

As technology advances, sticker maker machines are becoming more sophisticated, incorporating features that enhance performance and usability. One notable advancement is the integration of digital interfaces and connectivity options. Machines equipped with Wi-Fi or Bluetooth connectivity allow for seamless operation and easy integration with design software, enabling remote control and monitoring.

Another significant feature is the inclusion of automated calibration and alignment systems. These systems ensure precise cuts and reduce the need for manual adjustments, enhancing accuracy and reducing waste. Additionally, some machines now come with built-in sensors that detect material type and thickness, automatically adjusting settings for optimal cutting performance.

The use of advanced materials and construction techniques has also improved the durability and lifespan of sticker maker machines. Machines built with high-grade stainless steel components offer better resistance to wear and tear, ensuring long-term reliability. Furthermore, the incorporation of energy-efficient motors and components reduces power consumption, making these machines more environmentally friendly and cost-effective to operate.

Regulatory Compliance and Certifications

Regulatory compliance and certifications are critical considerations, especially for industrial applications. Machines that comply with international safety standards, such as ISO and CE certifications, ensure safe operation and adherence to quality benchmarks. These certifications indicate that the machine has undergone rigorous testing and meets the required safety and performance criteria.

In addition to safety standards, compliance with environmental regulations is becoming increasingly important. Machines that adhere to eco-friendly standards, such as RoHS (Restriction of Hazardous Substances), minimize the environmental impact by reducing the use of harmful materials. Ensuring that your sticker maker machine complies with these regulations can not only enhance your brand’s reputation but also align with global sustainability goals.

Ease of Use and Initial Setup Complexity

The ease of use and complexity of initial setup are important factors that can influence your choice of a sticker maker machine. User-friendly machines with clear instructions and intuitive controls reduce the learning curve, allowing operators to get up to speed quickly. Machines that come with pre-set templates and automated setup features further simplify the process, ensuring that even novice users can achieve professional results.

Initial setup complexity can vary significantly between different models. Machines that require extensive manual adjustments and calibrations can be time-consuming and may require specialized knowledge. Conversely, machines with plug-and-play features and automated setup processes can be operational within minutes, saving valuable time and reducing the potential for errors.

Conclusion

In summary, selecting the right sticker maker machine involves careful consideration of various factors, including types and styles, performance, design, technical specifications, and price range. Staying abreast of the latest technology features and ensuring regulatory compliance can further enhance your decision-making process. By evaluating these aspects, you can choose a machine that meets your specific needs, ensuring optimal performance and quality in your sticker production operations.